-

Description

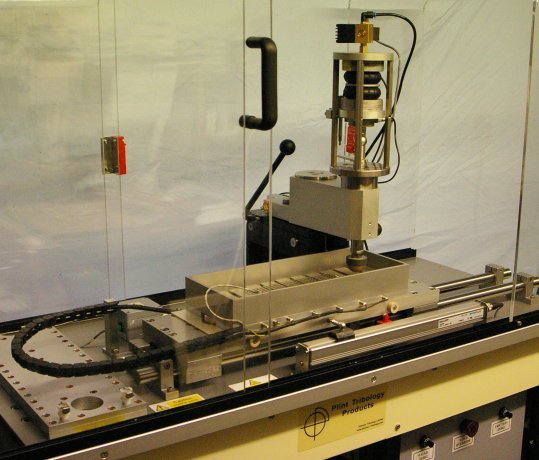

The TE 37 Bowden-Leben machine is a conventional long stroke, low speed, reciprocating tribometer, combining an electro-mechanical ball-screw actuator and linear slide with the proven loading and friction measuring assembly of the TE 67 Pin on Disc Machine.

The pin specimen carrier assembly consists of a massive aluminium block pivoted about a vertical axis through its centre. A precision piston with a pin specimen holder is loaded vertically downwards directly above the contact point, by means of a servo-controlled pneumatic bellows, with a load range of 25-1,000 N at 7.5 bar operating pressure. An in-line compression load cell measures the applied load and provides load feedback for control. Both steady and fluctuating loads with a sine or triangular waveform can be applied.

The entire pin carrier assembly can be rotated out of its locked horizontal position thus separating the contact and allowing access for changing specimens and examining the surfaces.

A strain gauge load cell is mounted at the rear of the pin carrier block, preventing the block pivoting about its central axis. This transducer therefore measures the force exerted on the pin during sliding. A retaining clamp maintains the pin carrier in contact with the transducer at all times, ensuring that bi-directional forces generated in pin on disc and reciprocating contacts are measured.

An indication of wear processes going on in the contact is given by an LVDT mounted in the loading assembly. This transducer measures the movements of the piston during a test.

The pin loading capsule is electrically isolated from the carrier block and therefore from the specimen. This allows a small potential to be applied across the pin/disc contact from a Lunn-Furey Contact Resistance Circuit.

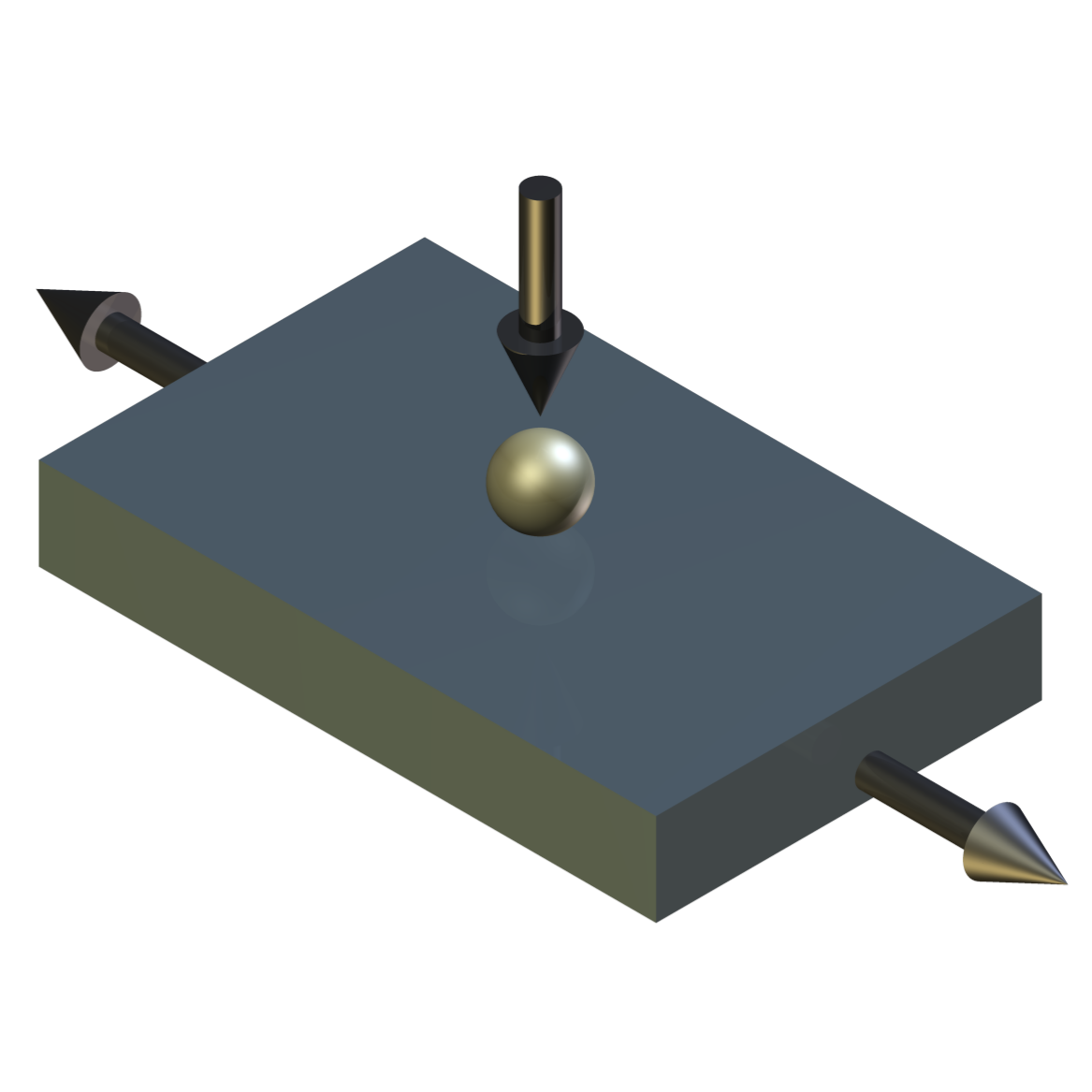

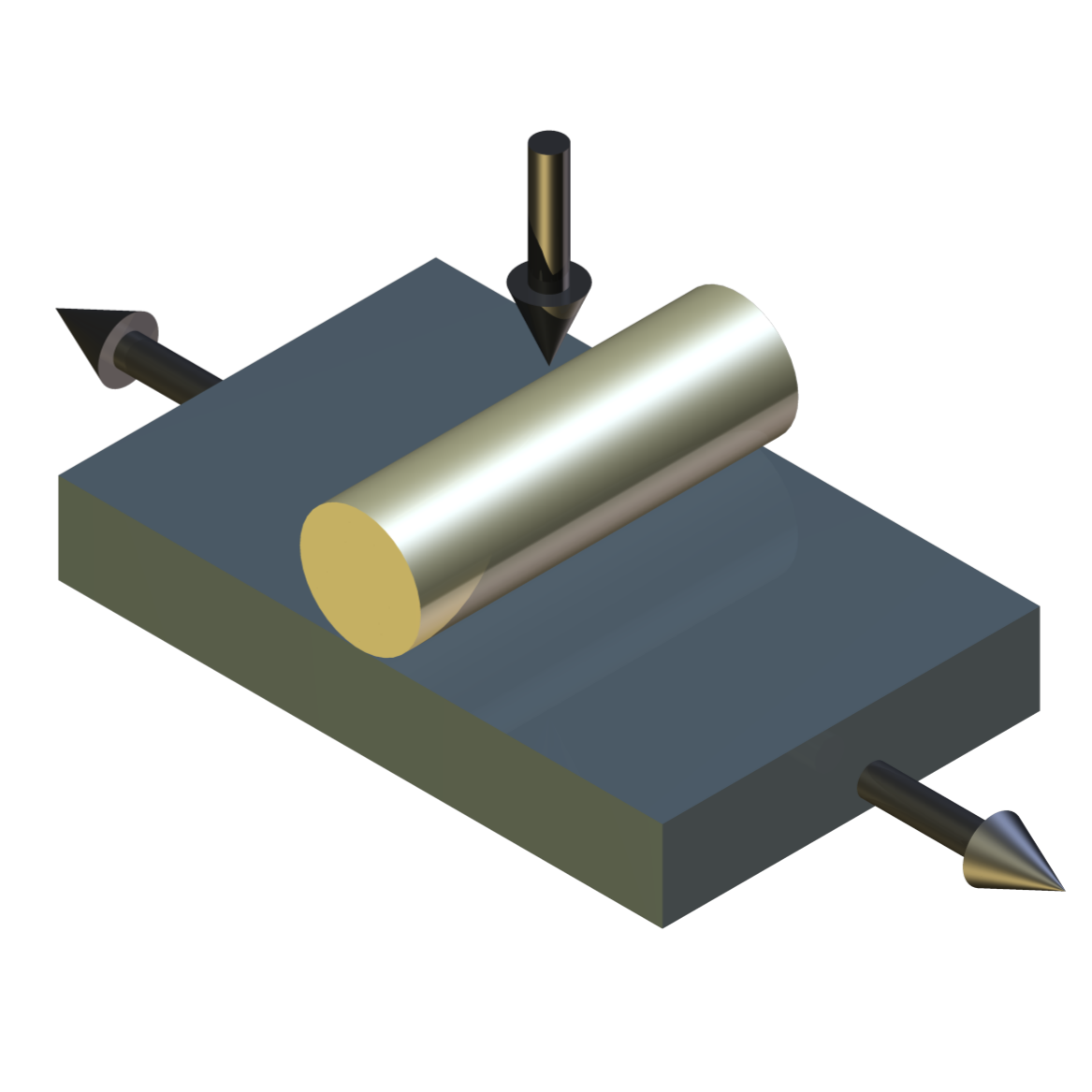

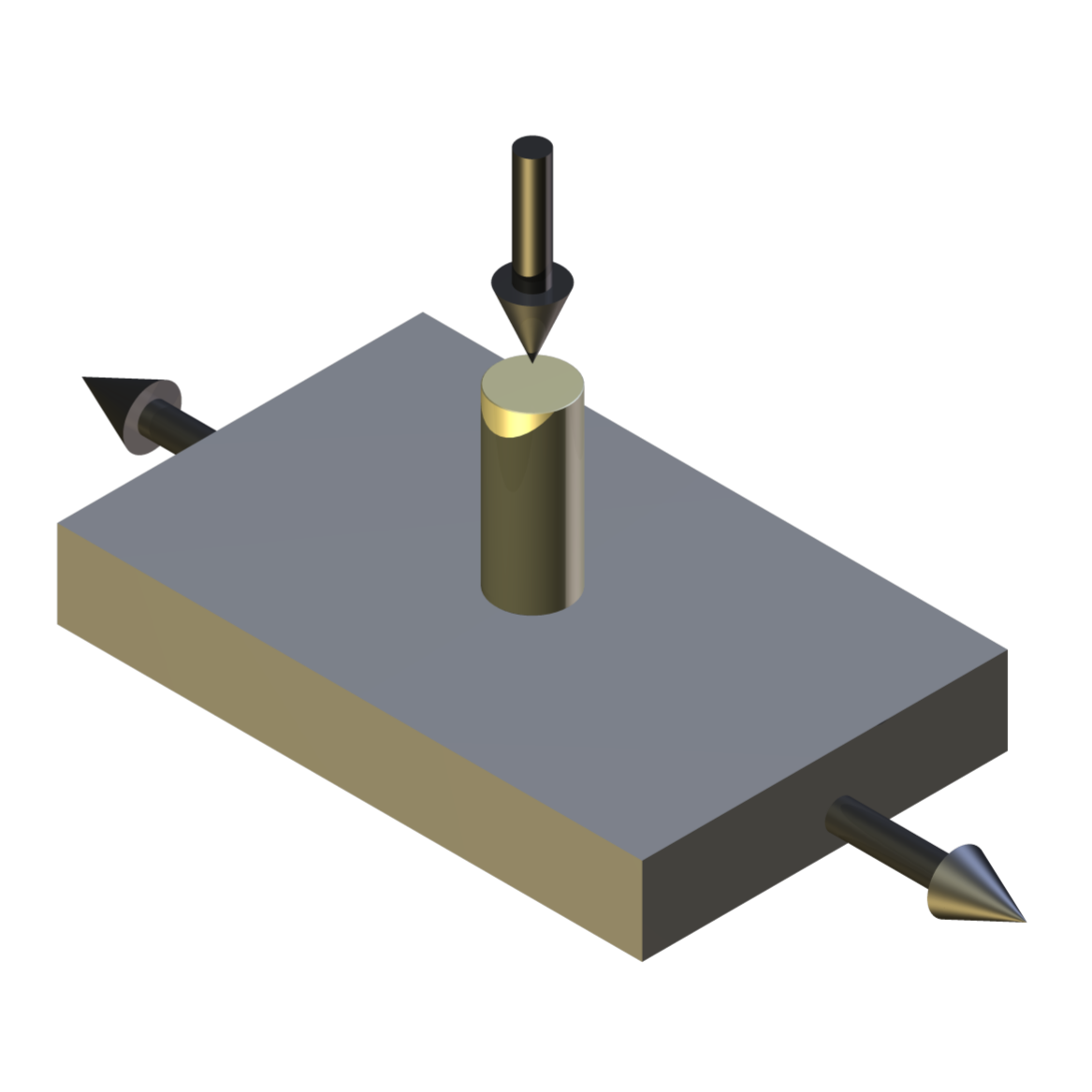

A large specimen bath is provided with both a heater pad and a cooler pad. In addition to conventional small pin or ball on plate type samples, the bath is large enough to accommodate large diameter area contact specimens, with a maximum contact diameter of 50 mm. The bottom of the bath has T-slots allowing ready fixing of different contact surfaces.Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Maximum Load on Stage: 2500 N Actuator Maximum Stroke: 280 mm Maximum Sliding Speed: 100 mm/s Maximum Repetition Rate: 0.3 Hz Load Range: 50 to 2500 N Cyclic Loading Amplitude: Up to 50% of set point Cyclic Loading Type: Sine wave or triangular wave Cyclic Loading Rate: 1 Hz maximum Load Bellows Capacity: 420 N/bar Bellows Maximum Pressure: 8 bar Air Pressure for 2500 N: 6 bar Friction Force: 0 to 50 N and 0 to 2,000 N Displacement Measurement: Range: 0 to 2.5 mm (LVDT) Resolution: 1 µm Maximum Bath Temperature: 200°C Data Acquisition: 12 bit resolution @ maximum 10 Hz Controlled Parameters Load Traverse Speed Stroke Length Traverse Speed Profile Sample Lift, Drop and Dwell Test Duration Recorded Parameters Load Traverse Speed Stroke Displacement Friction Force Specimen Displacement Temperature (Ambient/Sample) Number of Cycles Test Duration Friction Coefficient Sliding Distance Services Electricity: 220/240V, single phase, 50 Hz, 3 kW 110/120 V, single phase, 60 Hz, 3 kW Clean, dry air: 0.4 cubic metres per minute at 8 bar -

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com