-

Description

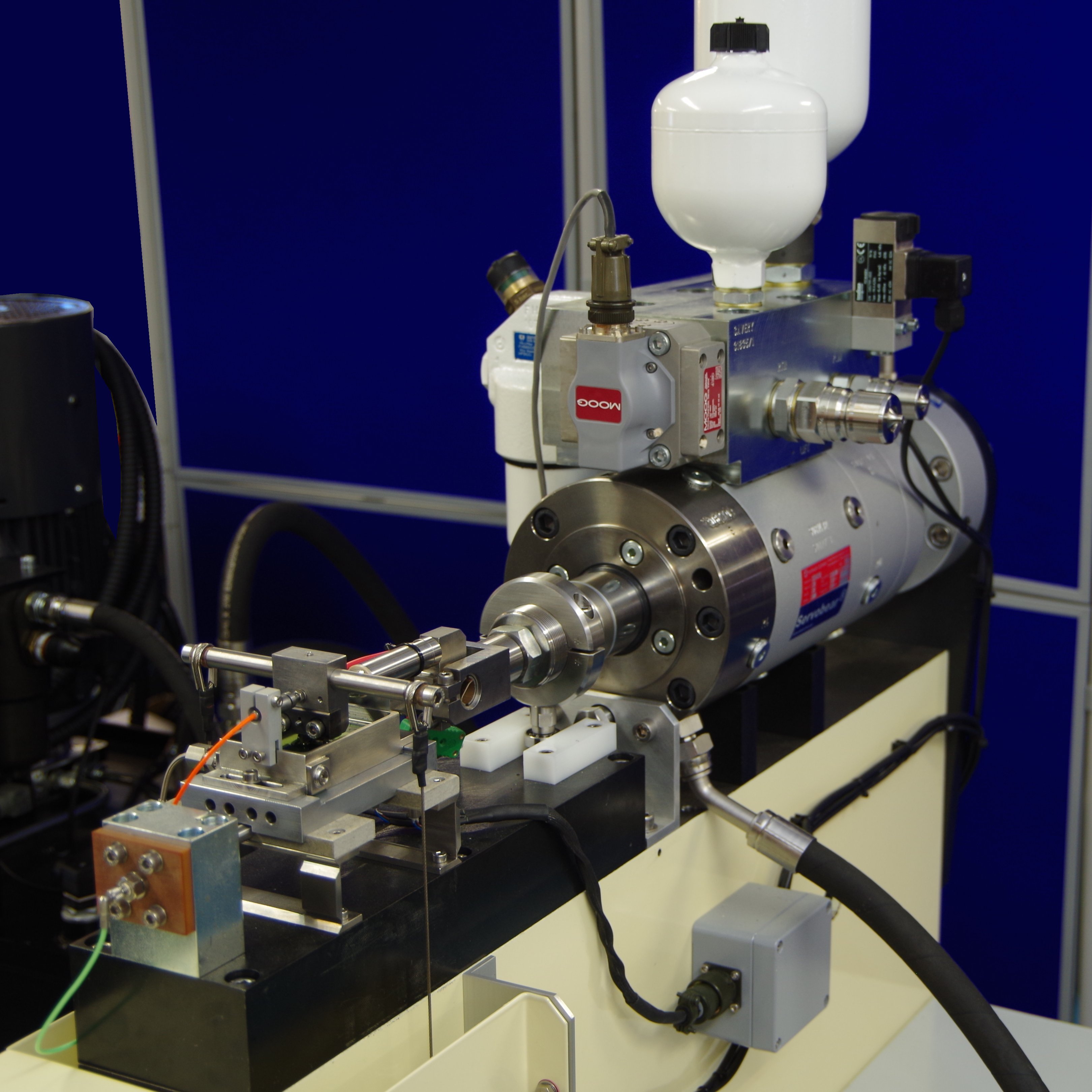

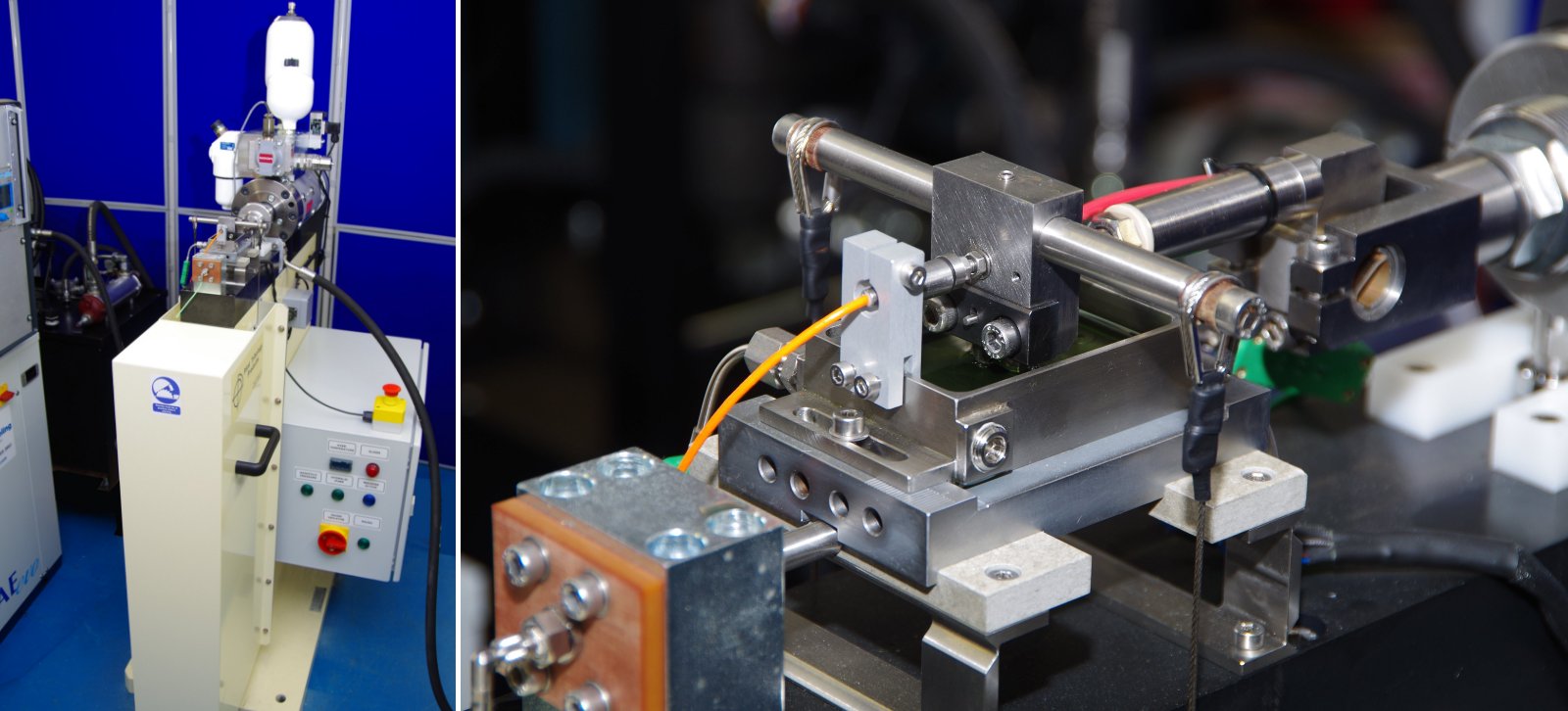

The DN 44 Dry & Lubricated Reciprocating Sliding & Fretting Machine incorporates a servo hydraulic actuator driven by a high frequency analogue controller, which derives its set points via a 16 bit control and data acquisition card from a standard PC, running COMPEND 2020 software. Real time adaptive control features provided within the software allows high precision control of the actuator when working against highly non-linear loads. Sine, square, triangular and random waveforms may be programmed and, depending on the physical capabilities of the hydraulic system, oscillating frequencies up to 200 Hz may be controlled.

The machine is designed for fretting and fretting fatigue tests with nominal relative movement between contacting surfaces in the range 20 microns to 80 microns. It may also be used for sliding reciprocating tests at strokes up to 20 mm. Servo hydraulic actuation with piezo transducer friction force measurement and servo controlled loading with force transducer feedback.

DN 44/1 Small Perturbation Signal Generator

This optional additional signal generator and signal analysis system allows combined sliding motion with co-axial vibration to be generated. The standard servo amplifier incorporates a summing junction on the input stage with dual inputs. This means that with the addition of a second signal generator, two separate signal inputs, one low frequency and long stroke and one high frequency and short stroke, can be combined, thus producing reciprocating motion with superimposed vibration from a single servo hydraulic actuator.

-

Technical Specifications

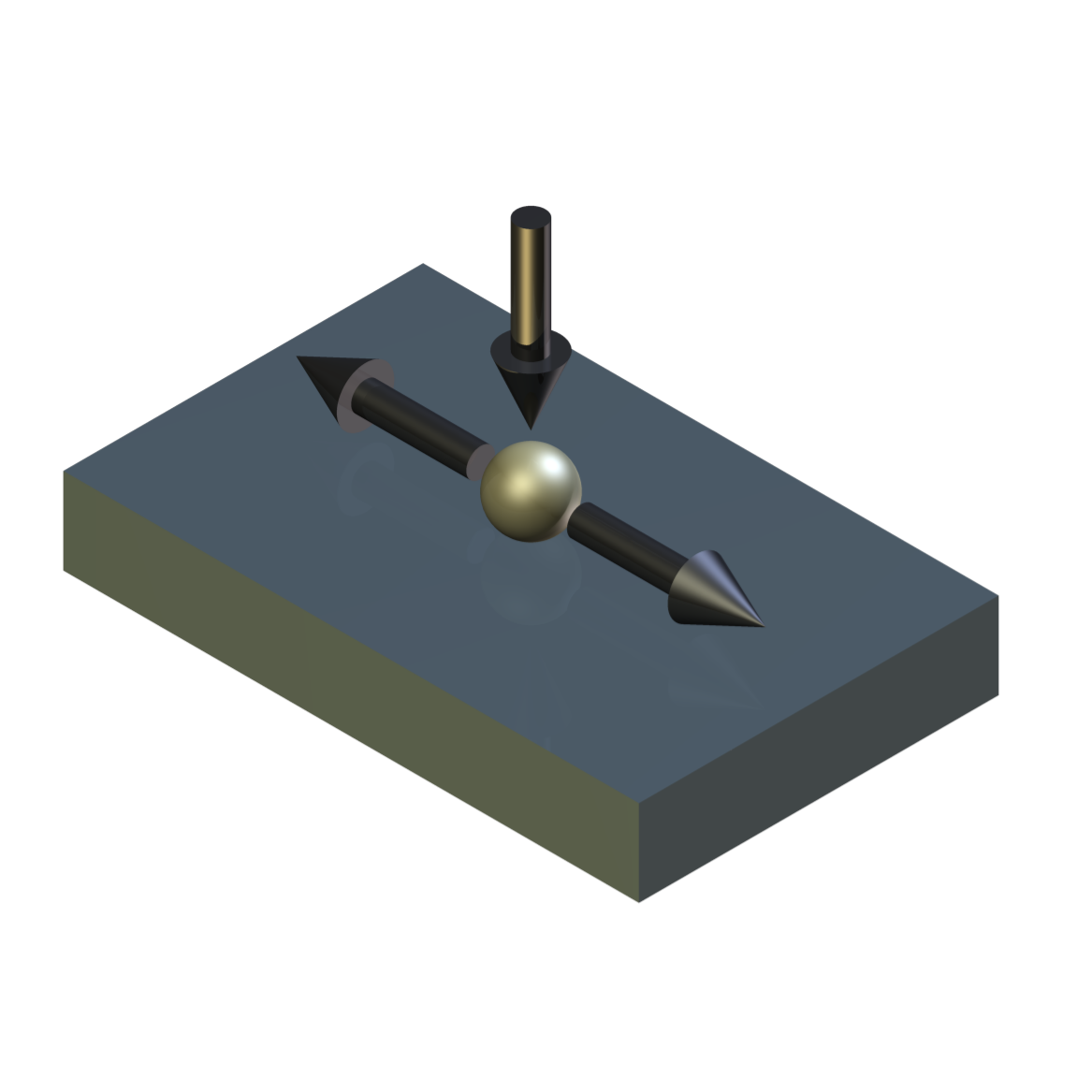

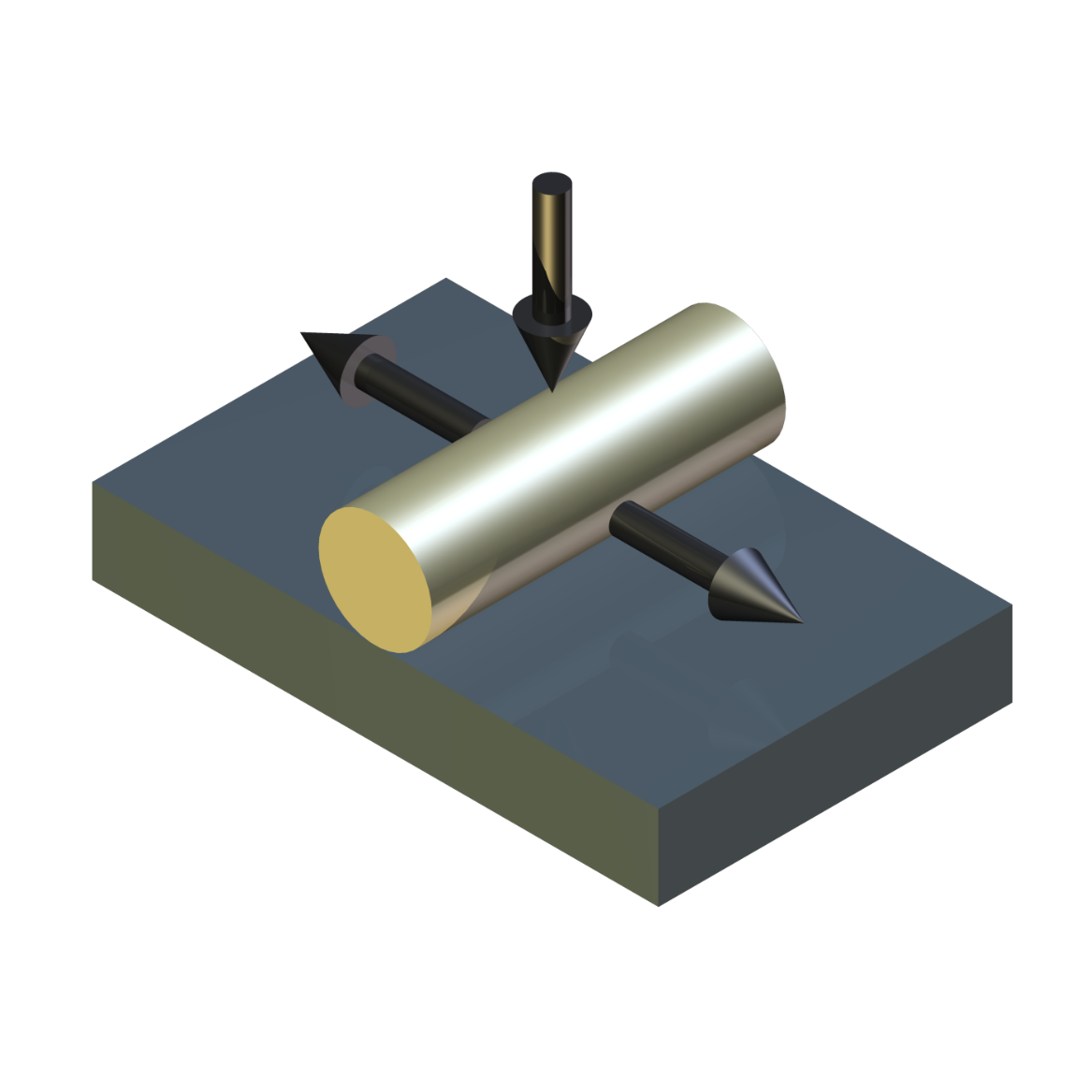

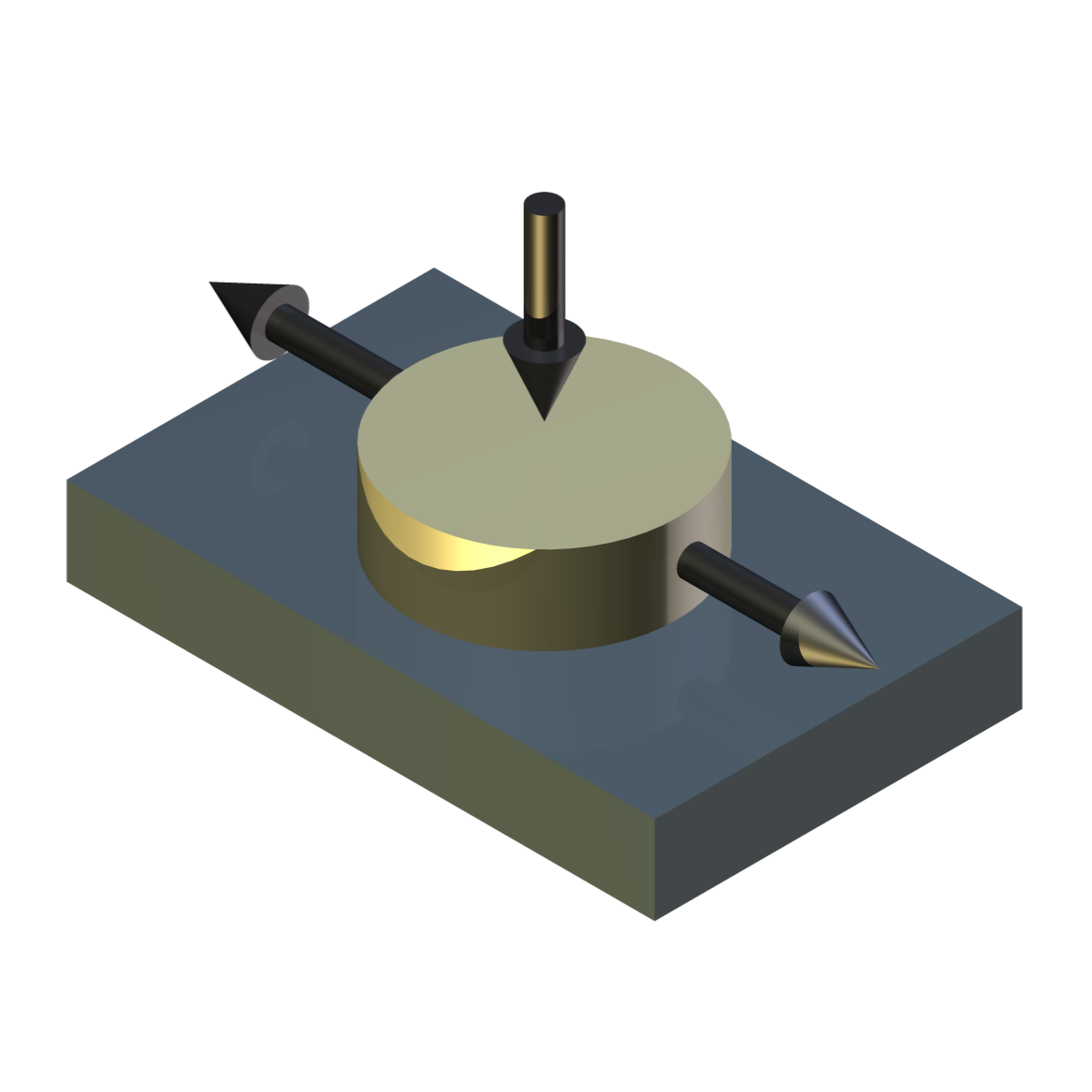

Type of contact: Ball/Flat Flat/Flat Line/Flat Type of Movement: Sine, Square, Triangular and Random Load: 5 to 1,000 N Friction Force: +/-500 N Maximum Stroke – continuously variable: 10 microns to 20 mm Frequency: 0.1 Hz to 200 Hz Environment: Dry or Lubricated Temperature: Ambient to 600°C Super High Response Servo Valve: 12 l/min Actuator Bearings: Hydrostatic Dynamic Load: 5.7 kN Static Load: 8.6 kN Hydraulic Power Pack: 12 l/min at 250 bar High Speed Interface: USB ADC Resolution: 16 bit Number of Input Channels: 1 to 6 Maximum Data Rate: All channels at 50 kHz Interface: Serial Link Interface Module Software: COMPEND 2000 DN 44/1 Small Perturbation Signal Generator Type of Movement: Sinusoidal sliding stroke with co-linear superimposed sinusoidal perturbation Sliding Motion: Maximum Stroke: 20 mm (Amplitude: 10 mm) Type of Movement: Sinusoidal Frequency (FS): 0 to 5 Hz Vibration Motion: Stroke/Frequency: 200 microns (Amplitude 100 microns) @ 0 to 200 Hz 100 microns (Amplitude 50 microns) @ 0 to 300 Hz Frequency (FP): 0 – 300 Hz Control Requirements: FP must be greater than FS x 20 Controlled Parameters Frequency Stroke Load Temperature Test Duration Measured Parameters Frequency Stroke Load Friction Temperature Electrical Contact Resistance Services Electricity: 380/415V, three phase + neutral, 50 Hz, 7.5 kW 380/415V, three phase + neutral, 60 Hz, 7.5 kW Mains water and drain: 10 l/min (typical) -

Index Tags

-