HIGH THROUGHPUT TRIBOMETER

• Single function

• Multi-station

• Simple to Operate

• Control via PLC

• Data exported on USB stick

Description

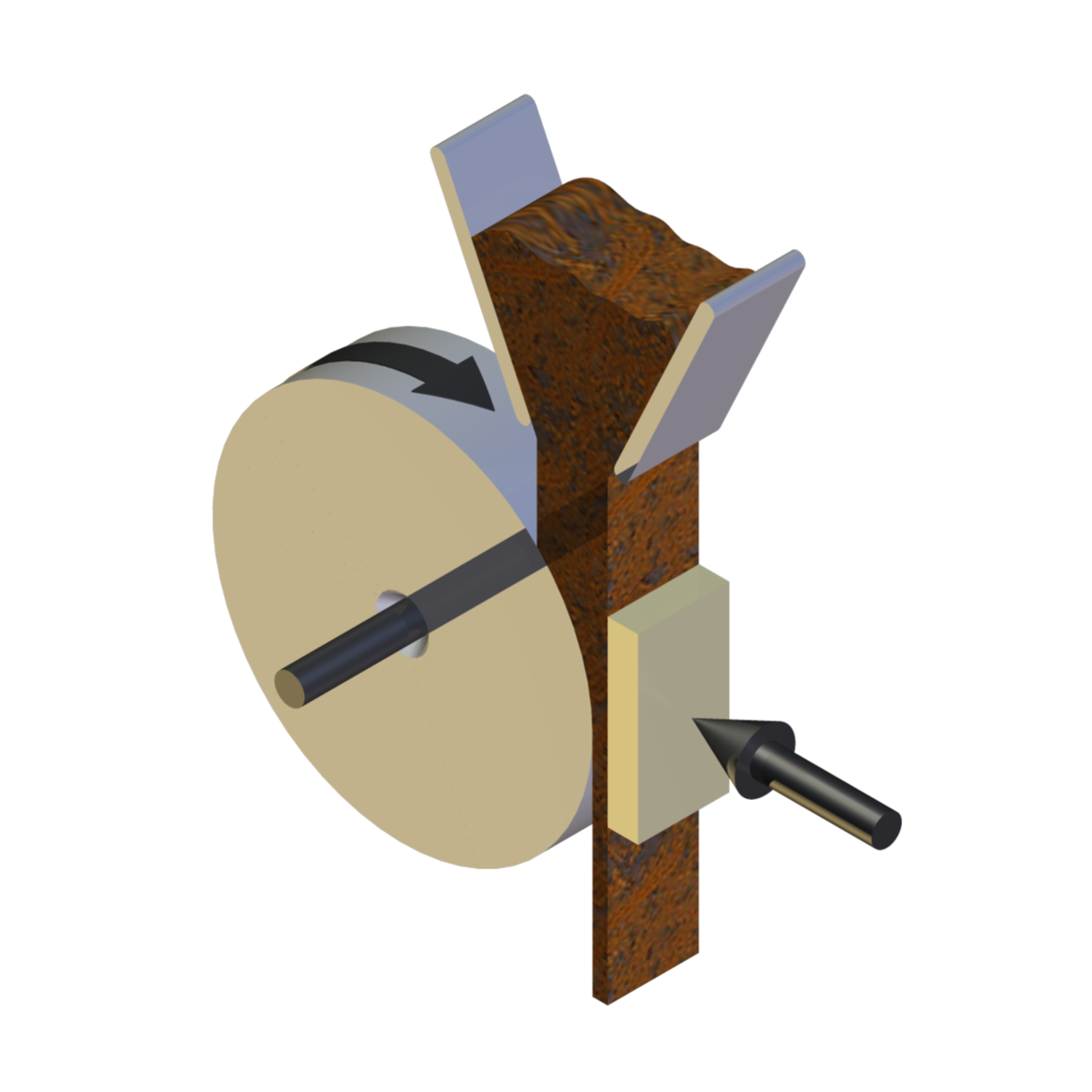

This instrument is a development of the TE 65 Sand/Wheel Abrasion Tester.

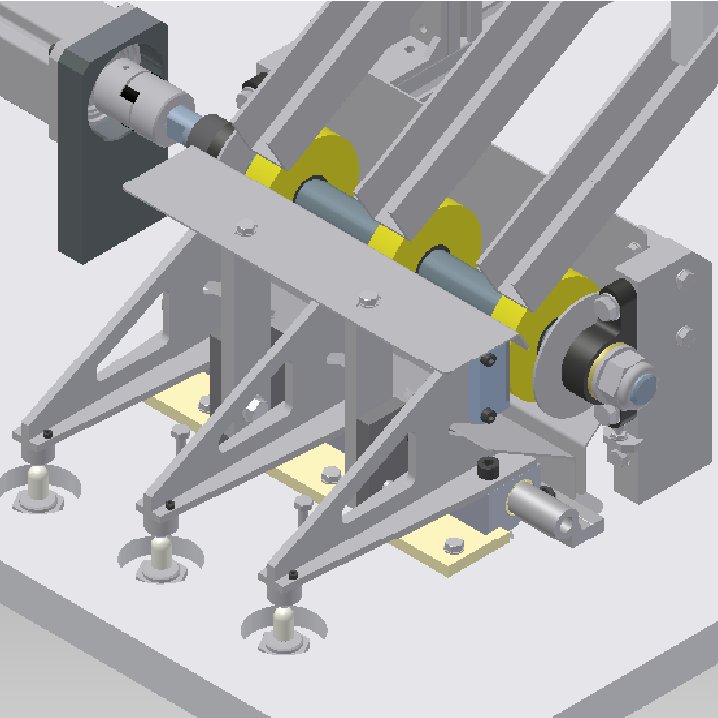

A standard urethane covered conveyer roller, with an outside diameter of 80 mm, and hardness of Shore A50, A70 or A90, can be purchased for less than 1/10th the cost of manufacture of a standard ASTM G65 wheel. Using these rollers results in a reduced cost per data point.

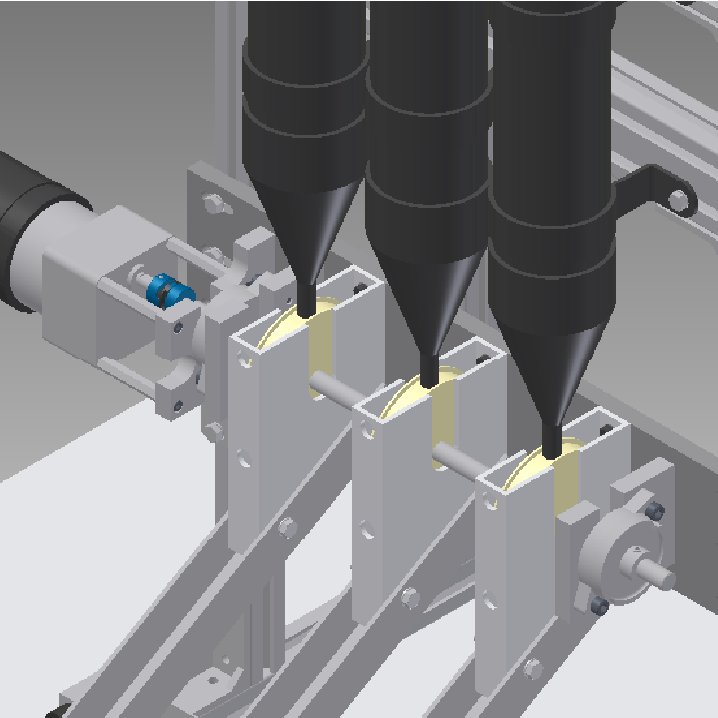

A precision abrasion feed system enhances control giving a range of constant feed rates and producing an even monolayer of particles on the wheel in front of the contact. The abradant is fed from a hopper to a rotating drum with a shallow groove on its surface. The feed rate is varied by adjusting the speed of the slotted drum. For wet tests, water can be introduced on to the wheel surface, just behind the chute. This means that fully wet tests can be carried out, with the mass flow of abradant well controlled.

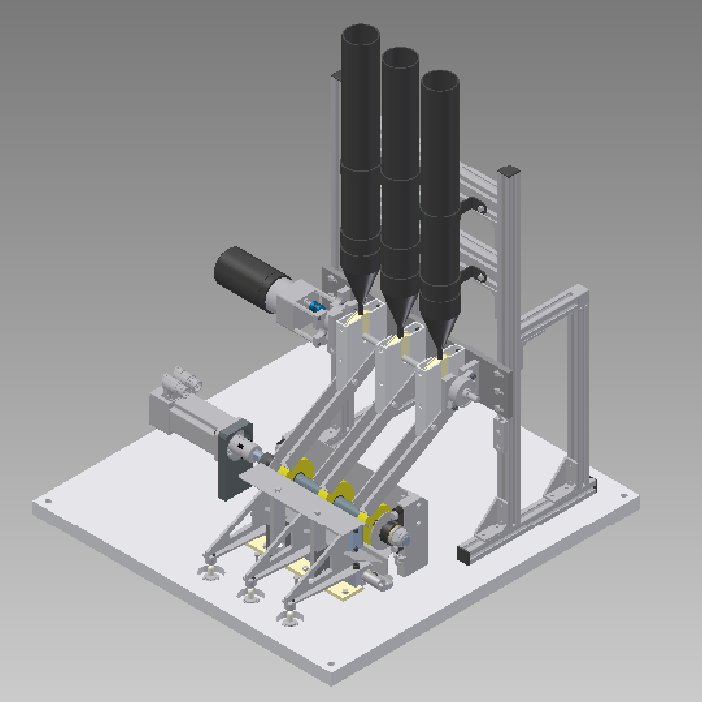

The machine is designed to be bench-mounted, with installation footprint kept to a minimum. It is simple to operate, so requires minimal training. Control is implemented with a PLC, with inputs via touch-screen.

-

Specifications

Motion Rotary Load 5 to 100 N Diameter 80 mm Speed 30 to 150 rpm Temperature Ambient °C Test Stations 3 Manually Set Parameters Load Yes – Pneumatic Rotational Speed Yes Test Duration Yes Data Logged Parameters N/A -