-

Description

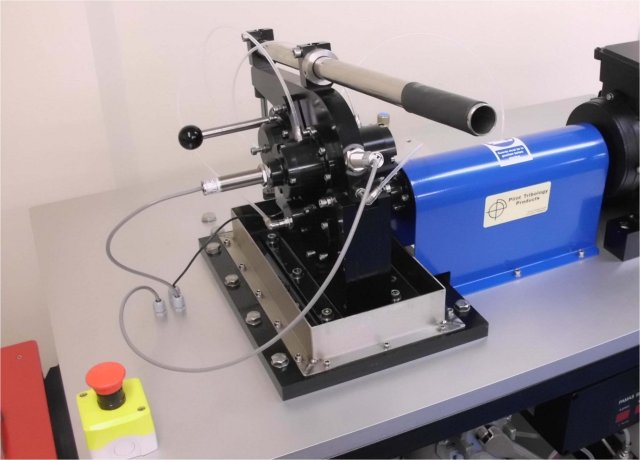

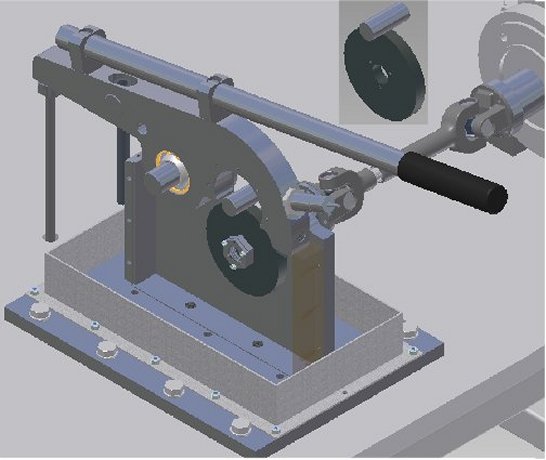

The RCF 1 Rolling Contact Fatigue Machine is a modified version of the TE 74S Two Roller Machine, with the drive to upper roller removed. The upper roller specimen is reduced to a simple cylindrical roller running in rolling contact with a driven lower roller. The machine is designed for performing rolling contact fatigue tests under conditions of elastohydrodynamic lubrication, with well filtered lubricant feed, thus minimizing the potential for adhesive, abrasive or oxidative wear or surface propagated micro-pitting; the intended failure mechanism is thus by pressure generated, sub-surface propagated, flaking or spalling.

The upper roller specimen is 20 mm in diameter and carried in roller bearings. The lower driving roller is 100 mm diameter and may have a flat or crowned surface. It is connected via a cardan shaft to an a.c. vector motor and may be driven at a maximum speed of 6,000 rpm. At this speed, the upper roller will rotate at 30,000 rpm, generating 500 fatigue cycles per second.

The “race-way” surface temperature (the running surface of the lower roller) and the upper roller end-face surface temperatures are monitored by pyrometers and a vibration sensor with adjustable level trigger circuit is provided for stopping the machine at the on-set of rolling contact fatigue.

Control and Data Acquisition

The RCF 1 has PC based sequence programmable control and data acquisition. This is provided by an integrated Serial Link Interface Module and COMPEND 2000 software running on a host PC, operating under Windows. Data is stored to hard disc in standard spread sheet compatible file formats (.csv or .tsv).

Tests are defined by a sequence of steps, each step containing set-point, data recording rates and alarm level information. Set-points may be adjusted by step change or ramp. The test sequence is followed unless interrupted by the operator or an alarm. Set-points may also be adjusted manually using on screen toggles.

-

Technical Specifications

Contact Configurations: Flat Roller on Flat Roller (Line Contact) Flat Roller on Crowned Roller (Elliptical Contact) Maximum Load: 12 kN Loading Rate: 50 N/s Temperature Range: Ambient to 150°C Upper Roller Diameter: 20 mm Lower Roller Diameter: 100 mm Upper Roller Max Speed: 30,000 rpm Lower Roller Max Speed: 6,000 rpm Motor: 1.5 kW a.c. vector motor, 2048 ppr encoder Interface: Serial Link Interface Module Software: COMPEND 2000 Controlled Parameters Motor speed Applied load Test fluid temperature Test duration Recorded Parameters Motor speed Applied load Lubricant inlet temperature Lower Roller Race-way Temperature Upper Roller End-face Temperature Vibration sensor output Services Electricity: 220/240 V, single phase, 50/60 Hz, 3 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Mains water and drain: 10 l/min (typical) -

Applications

elastohydrodynamic lubrication elliptical contact hertzian contact pitting rolling bearing materials rolling contact rolling contact fatigue rolling line contact white etching cracks -

Publications

-

User List

Launched 2013

SKF Holland -

Download the Machine Leaflet