-

• 15,000 rpm

• Single function

• Multi-station

• Easy to Operate

• Control via PLC

Description

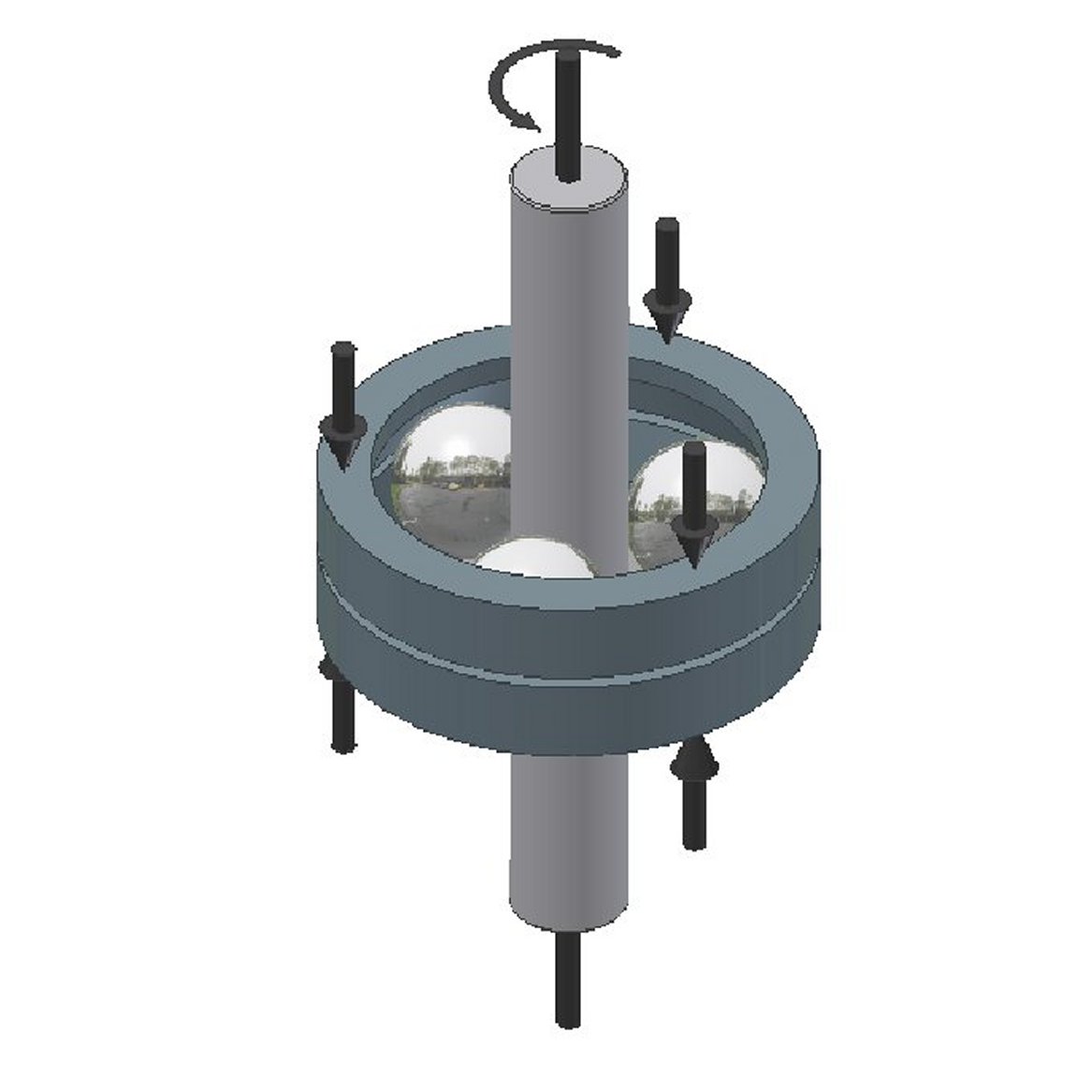

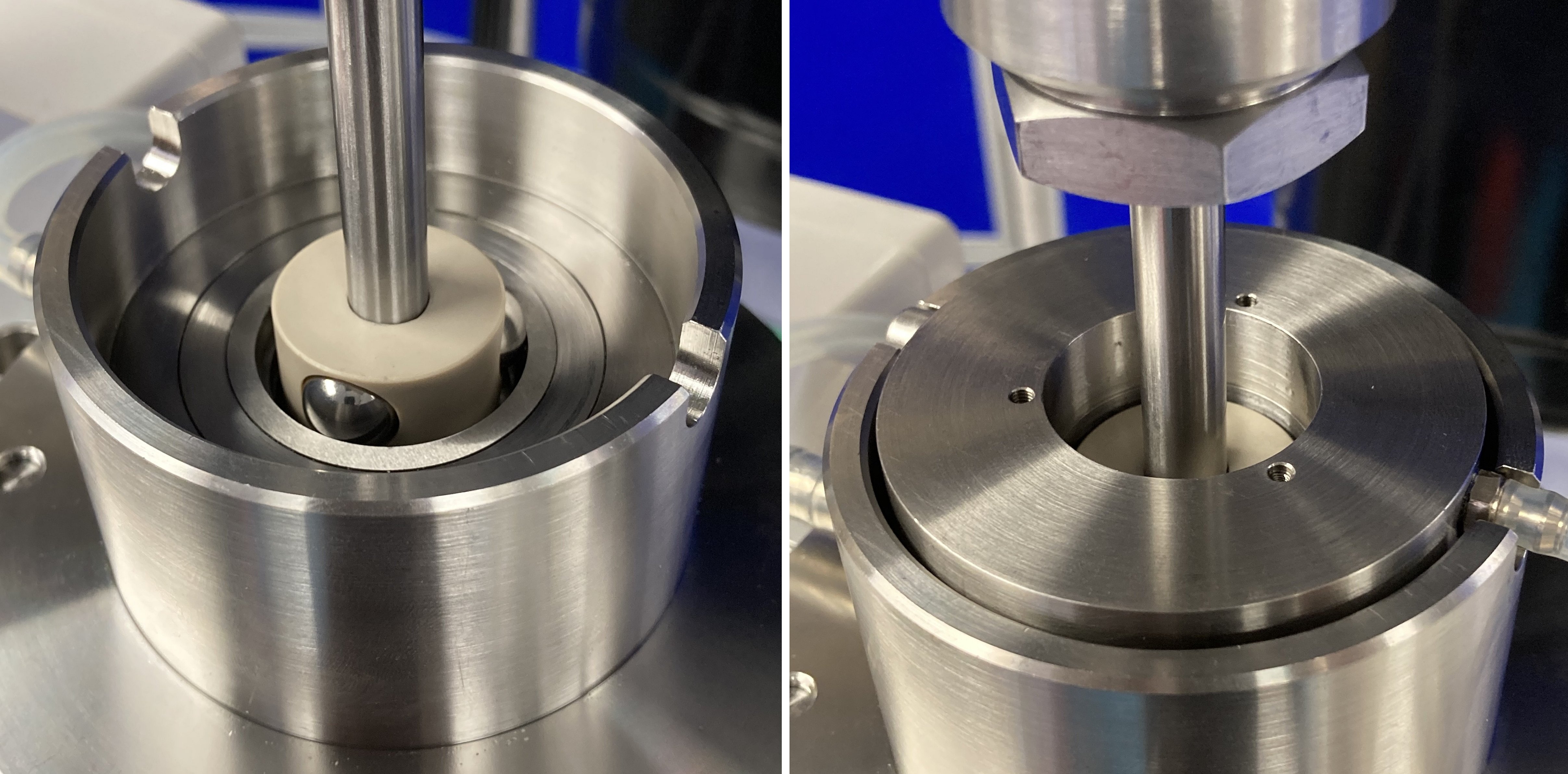

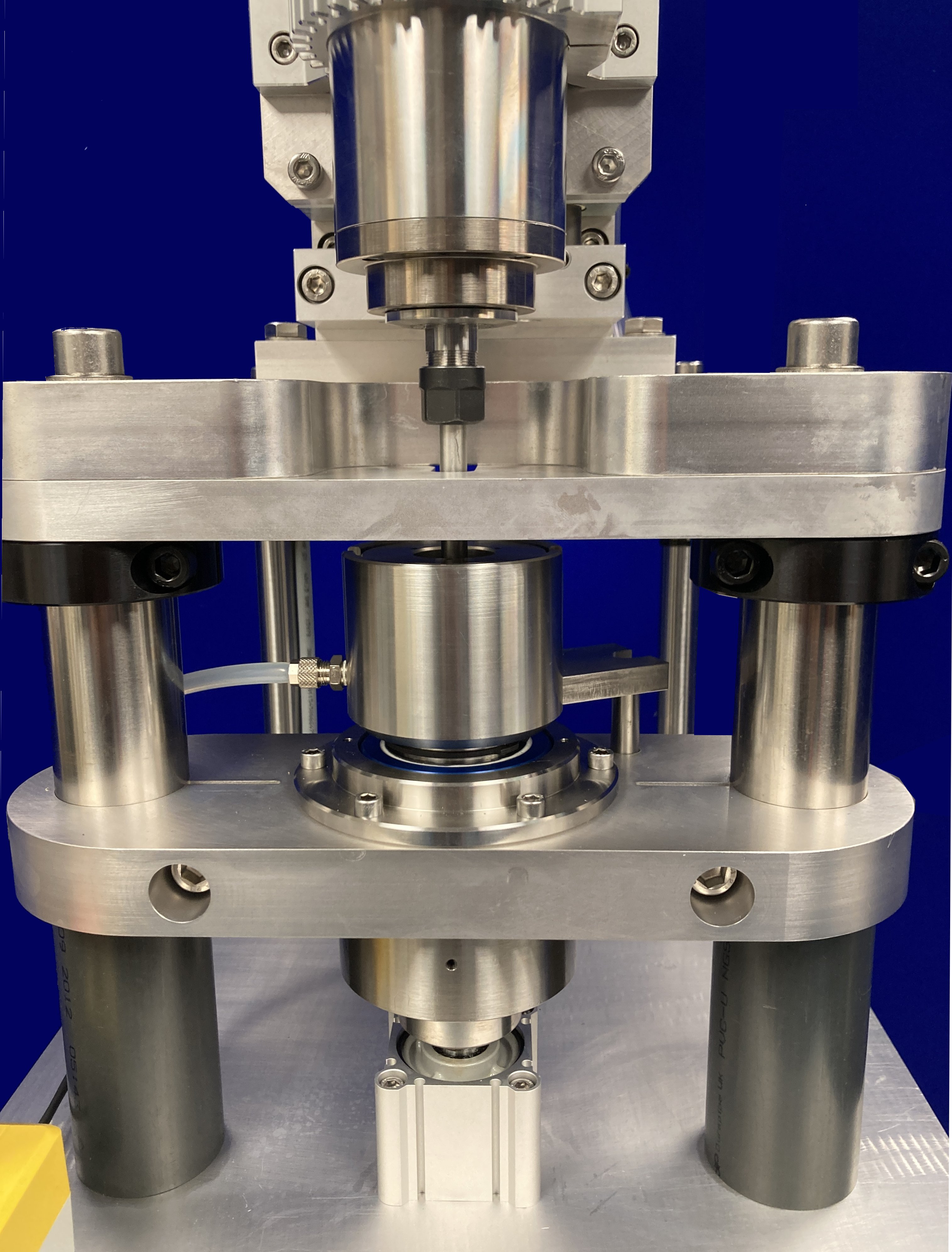

The RCF 6 machine is designed to run the standard three ball on rod rolling contact fatigue test geometry, in which three balls, separated by a retainer, are loaded against a rotating rod specimen, by applying an axial force across two taper bearing cups, mounted above and below the three balls.

The original design, dating from the 1970s, used pre-set compression springs to apply the axial load; in the RCF 6 machine, loads are applied by pneumatic actuator

The rotating rod is mounted in a simple collet and the rod position relative to the ball specimens may be adjusted to allow multiple tracks to be run on a single rod sample.

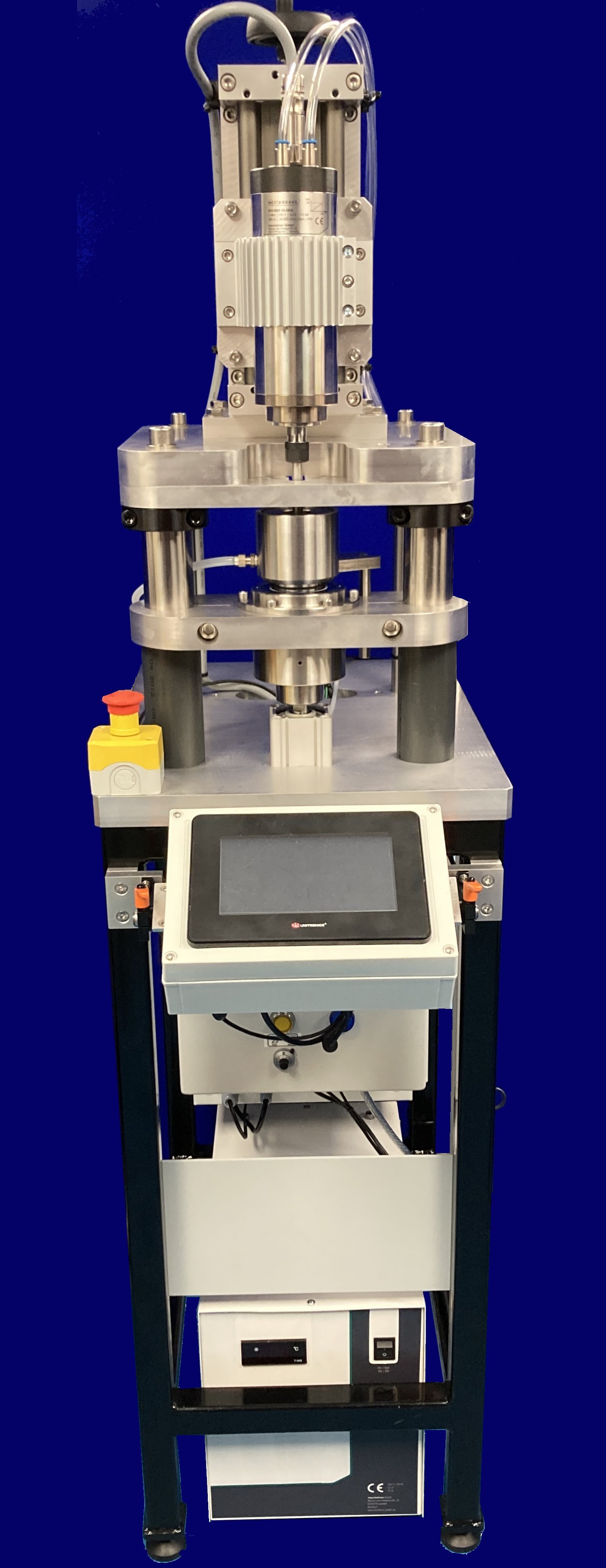

The machine is floor standing and designed to be installed either as a single unit or, more cost effectively, as a multi-unit installation, with the same pneumatic load applied to each test station.

Each test station incorporates a PLC, with inputs via touch-screen, for independent control of motor speed and test assembly temperature, plus a vibration sensor and adjustable level trigger circuit, for detecting rolling contact fatigue and stopping the motor.

Load actuators are connected in parallel to a common pneumatic supply, with a manually set precision regulator and a pressure transducer calibrated for load measurement. Manual valves are provided to allow individual actuators to be isolated from the pneumatic circuit, hence removing the load from the associated test station.

Each station has an independently controlled lubricant supply.

Although test station motor speeds and test assembly temperatures may be independently controlled, tests are run with the same load applied to each station. As rolling contact fatigue is a statistical process, each test station will record a different number of cycles to failure. Further to this, although the tests may be identical, they do not have to be started at the same time, but can be started and run asynchronously.

The machine installation footprint is kept to a minimum. It is simple to operate, so requires minimal training. -

Technical Specifications

Test Geometry: Ball on rod Rod Diameter: 9.53 mm and 10 mm Ball Diameter: 12.7 mm Motion: Rotary Contact Load: 200 to 1200 N Fatigue Cycles per Revolution: 2.3828 with 9.53 mm diameter rod 2.3654 with 10 mm diameter rod Speed: 300 to 15,000 rpm Motor: 1.4 kW @ 15,000 rpm Temperature: Ambient to 80°C Test Stations: Up to 6 Control: PLC Lubricant Service Module: Included Manually Controlled Parameters Load: Pneumatic – actuators in parallel Rotational Speed: Each test station independently controlled Temperature: Each test station independently controlled Vibration Level: Each test station Data Logged Parameters Load: Pressure transducer – one per installation Temperature: Yes – each test station Test Duration: Yes – each test station Services Electricity per Test Station: 220/240V, single phase, 50 Hz, 4.5 kW 110/120V, single phase, 60 Hz, 4.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Index Tags

ball on rod rolling contact fatigue hertzian contact high speed rolling contact fatigue macro-pitting pitting rolling bearing materials rolling contact fatigue machines -