-

Description

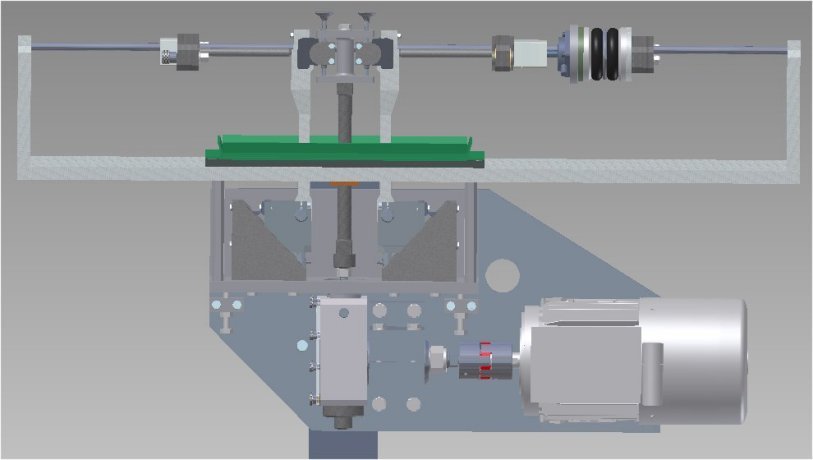

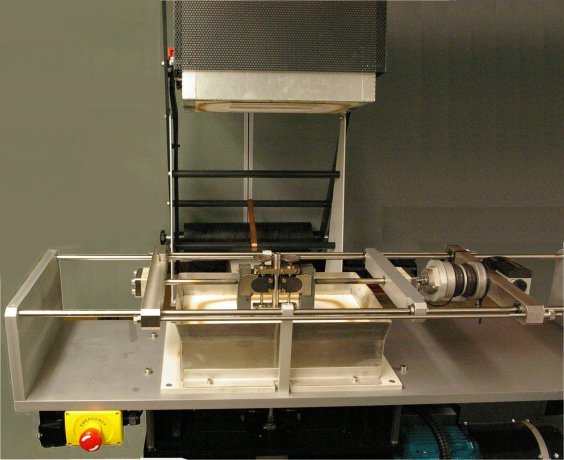

The TE 33 Engine Tribometer is a two-station, vertical axis, long stroke reciprocating tribometer, which combines the reciprocating drive mechanism from the TE 77 High Frequency Friction Machine with the specimen tooling of the DN 55 High Temperature Dry Sliding & Fretting Test Machine.

The test assembly is located vertically above the reciprocating drive assembly and comprises two fixed specimen arms supported on flexural pivot bearings, which are in turn mounted on linear flexure assemblies. Motion in a vertical direction is restrained by piezo force transducers.As each arm reacts against its own independent transducer, the friction between the each moving specimen and each fixed specimen is monitored independently. This allows two different material pairs to be tested simultaneously under identical conditions of load and temperature.

Load is applied to either side of the moving specimens by squeezing the two fixed specimen arms together by means of a servo controlled pneumatic bellows assembly, with force transducer feedback. This arrangement ensures that there is no bending moment acting on the moving specimen carrier.

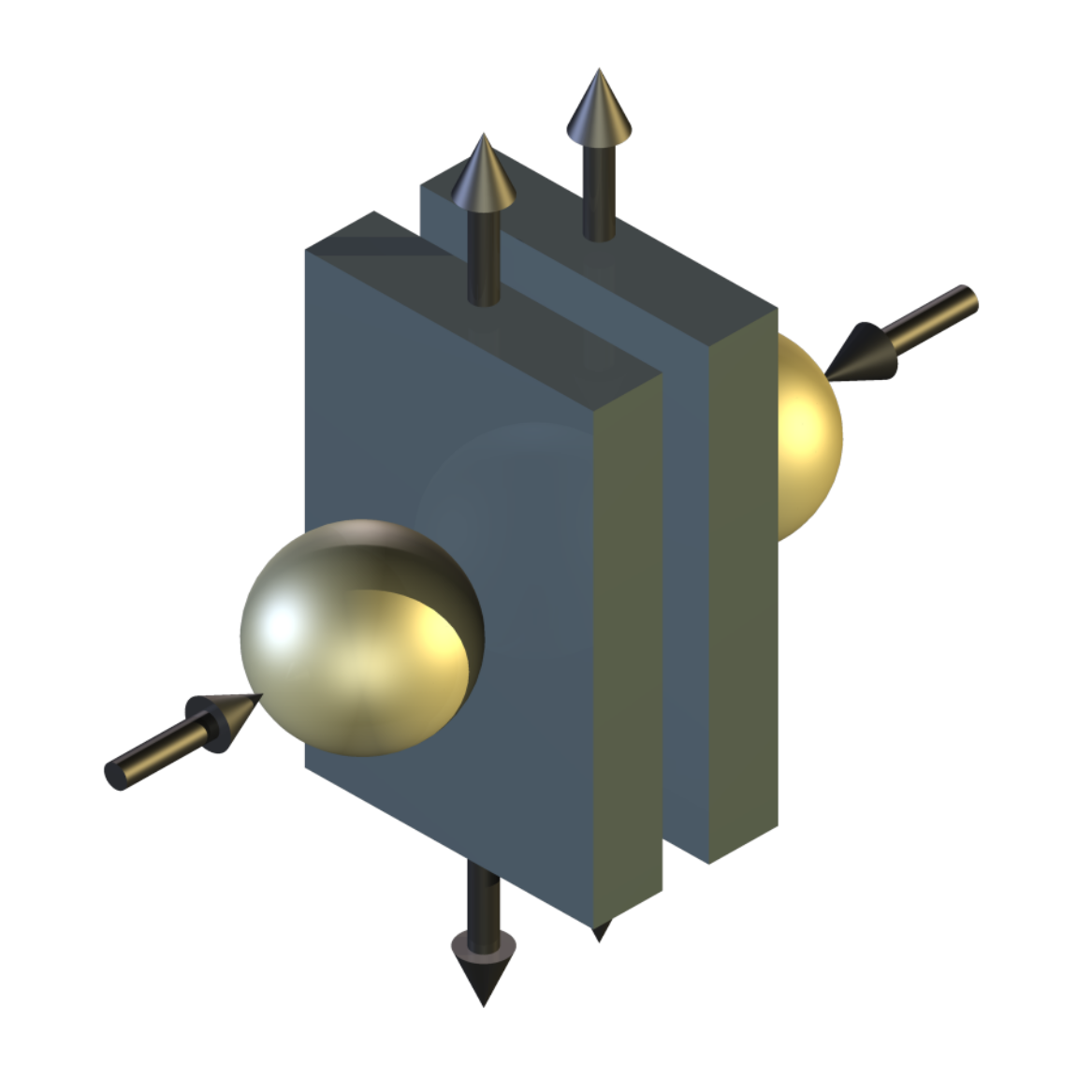

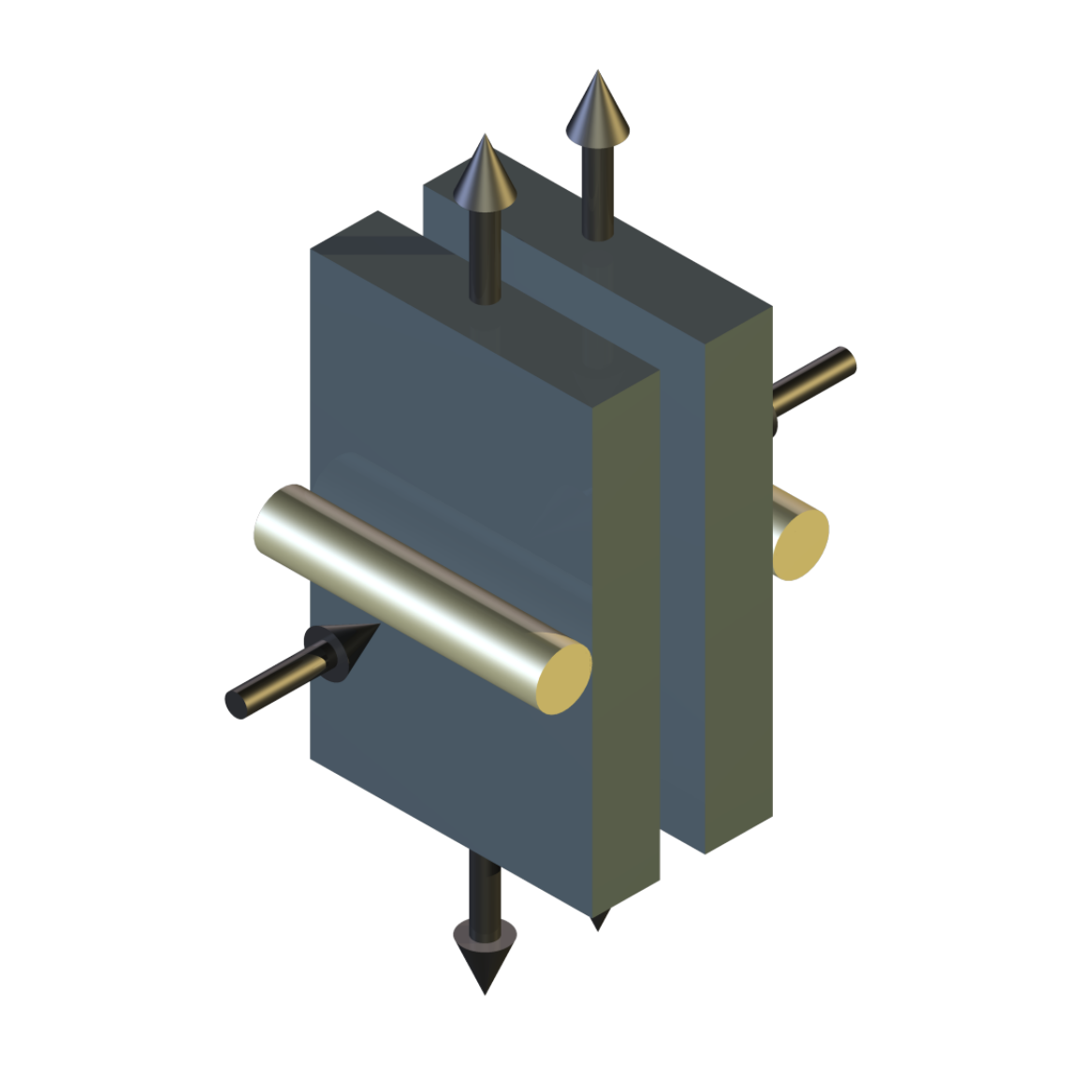

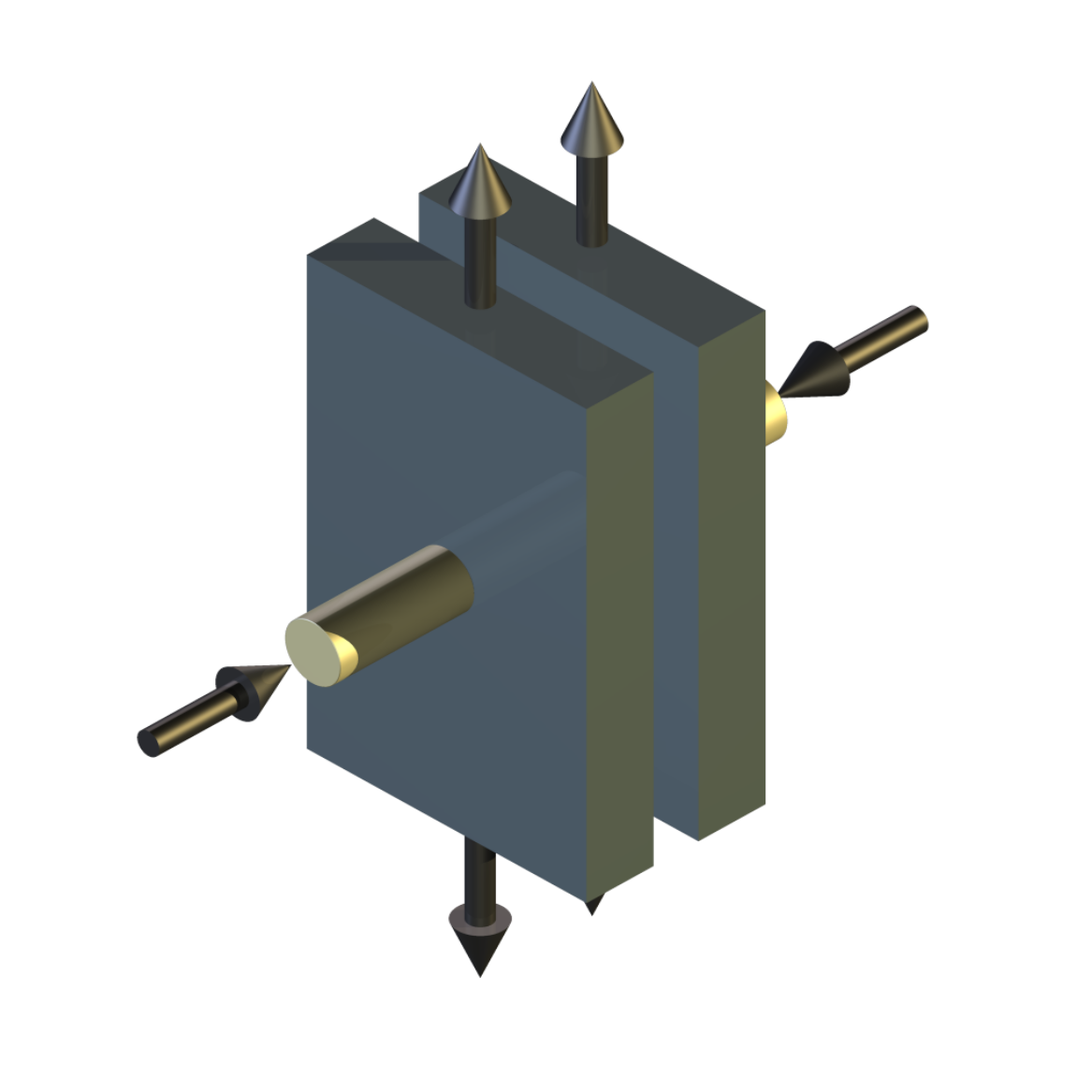

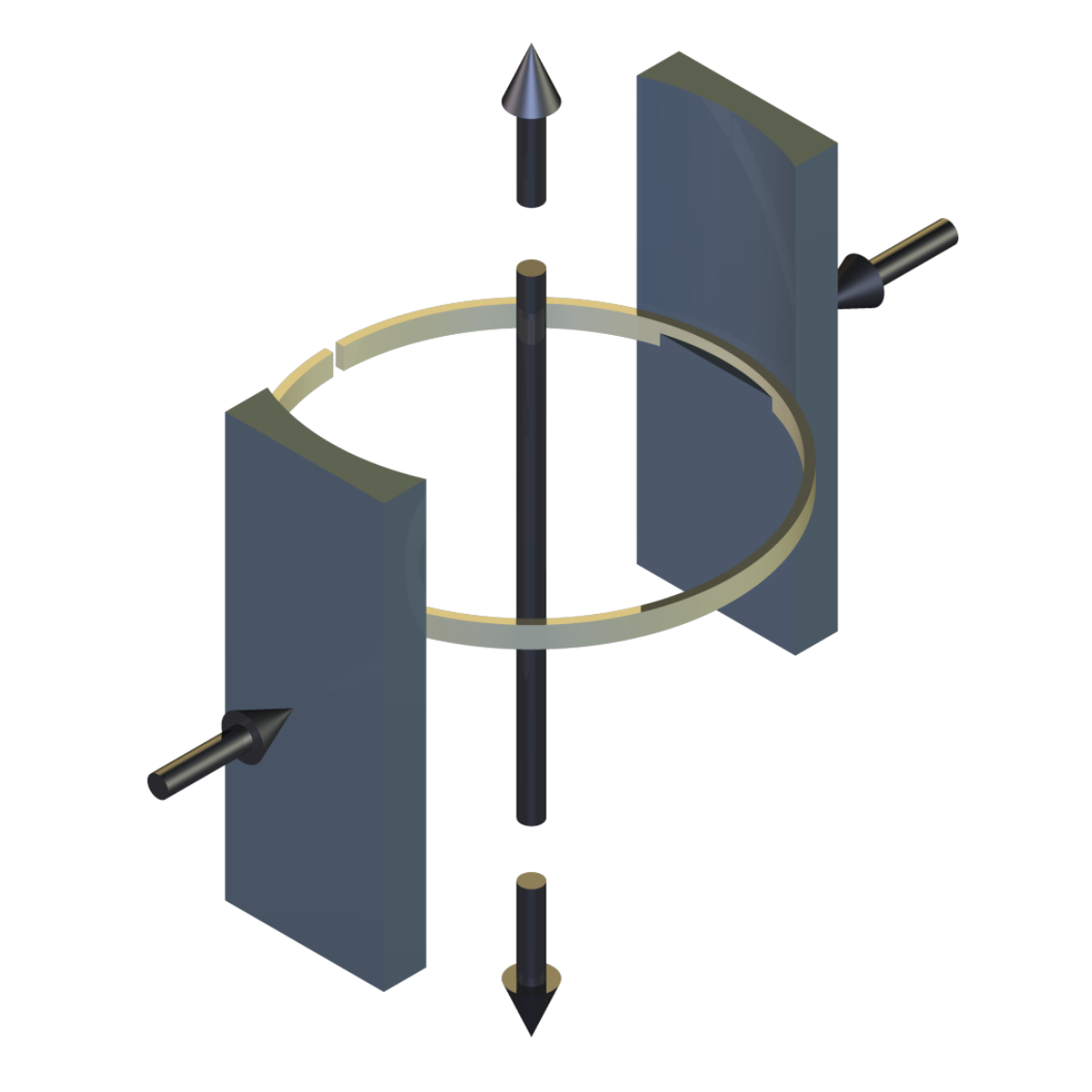

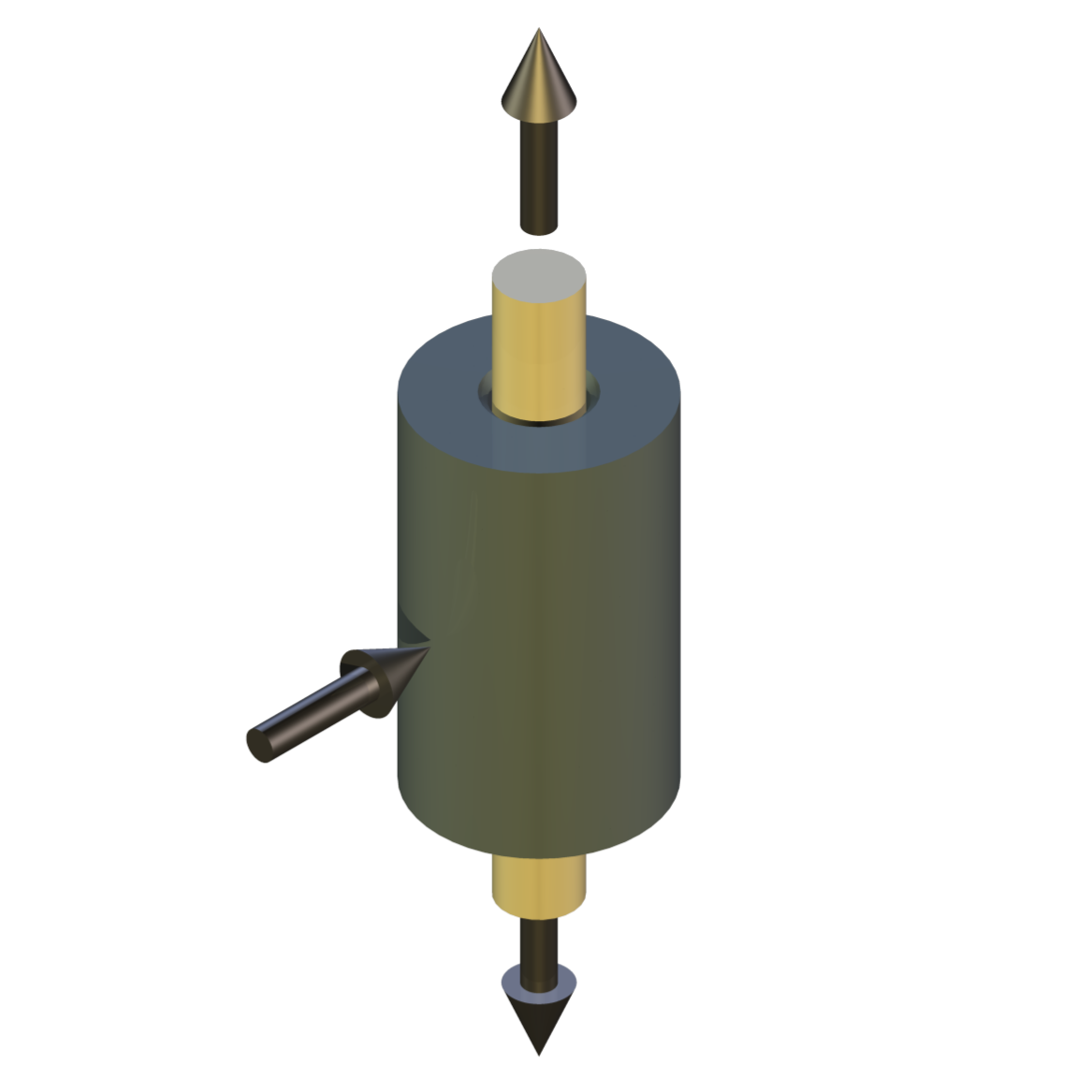

Tooling is provided for point, line and area contact configurations. An electrically heated furnace allows tests to be run at temperatures up to 1000°C.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Contact Configurations: Point Contact Line Contact Area Contact Optional Configurations: Piston-Ring (complete) on Cylinder Liner Valve Stem on Valve Guide Load Range: 5 to 1000 N Loading Rate: 50 N/s Temperature Range: Electric Furnace: 1000°C Temperature Sensor: k-type thermocouple Frequency Range: 2 to 50 Hz Stroke Range: See following tables Friction Transducer: Piezo-Electric Type Force Range: – 500 to 500 N Interface: Serial Link Interface Module Software: COMPEND 2000 Motor: 1.1 kW a.c. vector motor with 2048 ppr encoder Stroke Range Continuously Variable Cam – 0 to 12.5 mm Angle – degrees: Minimum – mm Maximum – mm 0 0 2 18 1.04 3.04 36 2.65 4.65 54 4.25 6.25 72 5.75 7.75 90 7.09 9.09 108 8.24 10.24 126 9.17 11.17 144 9.85 11.85 162 10.26 12.26 180 10.4 12.4 Step Variable 0 to 12.5 mm: Angle – degrees: Nominal Stroke – mm 0 0 18 1.94 36 3.83 54 5.63 72 7.29 90 8.77 108 10.03 126 11.05 144 11.79 162 12.25 180 12.5 Step Variable 12.5 to 25 mm: 0 12.5 18 13.05 36 14.26 54 15.97 72 17.89 90 19.8 108 21.54 126 23 144 24.09 162 24.77 180 25 Controlled Parameters Frequency Load Temperature Test Duration Measured Parameters Load Friction Temperature Frequency Friction Coefficient Services Electricity: 220/240 V, single phase, 50/60 Hz, neutral & earth, 4.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com