-

Description

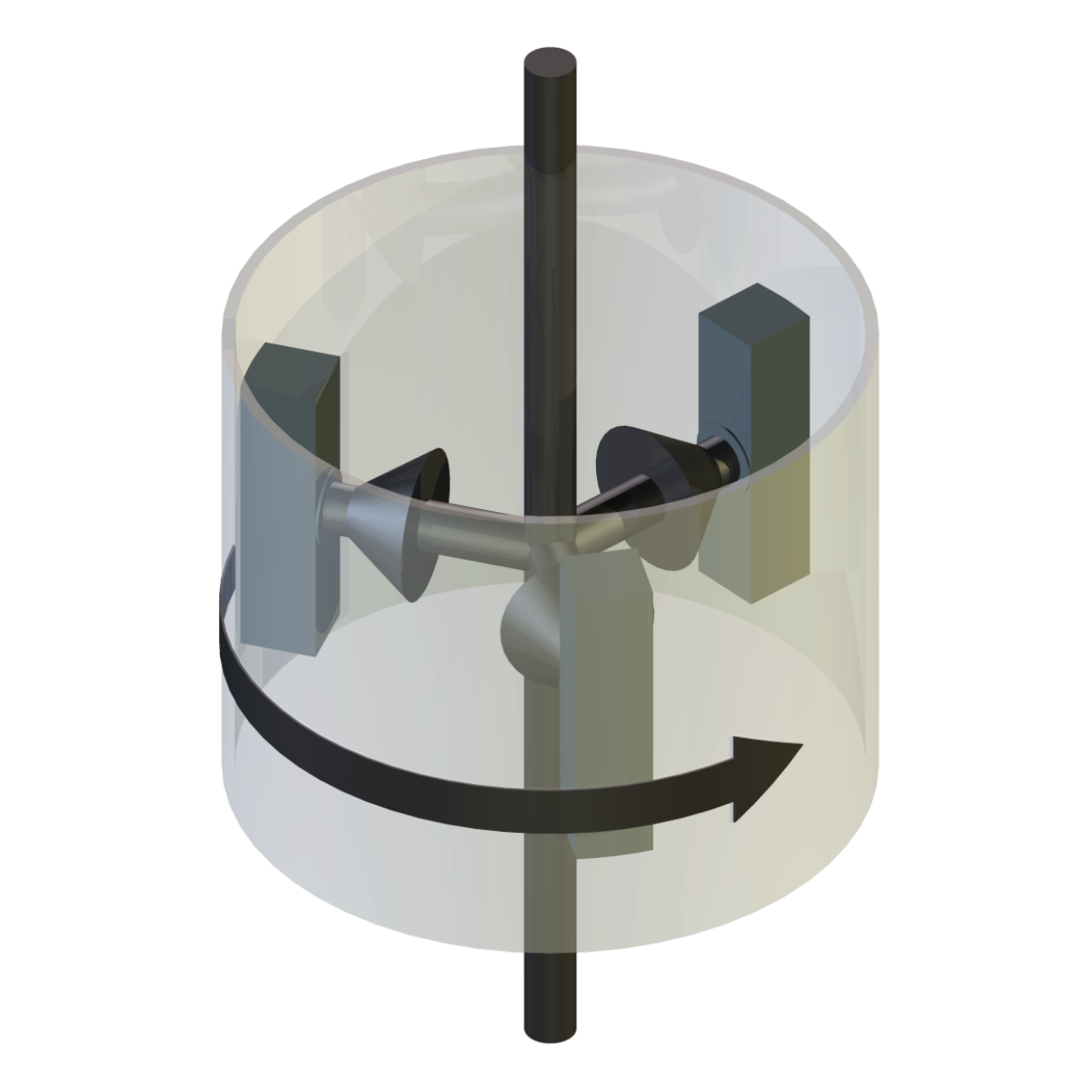

The TE 47 Three Station Ring/Liner Tribometer allows three idealised piston ring samples to be run against an unmodified cylinder liner. The key difference between this device and more conventional reciprocating tribometers is that instead of running up and down the liner, the samples are run around the internal circumference of the liner in either continuous rotation, allowing high sliding speeds to be achieved, or oscillating motion.

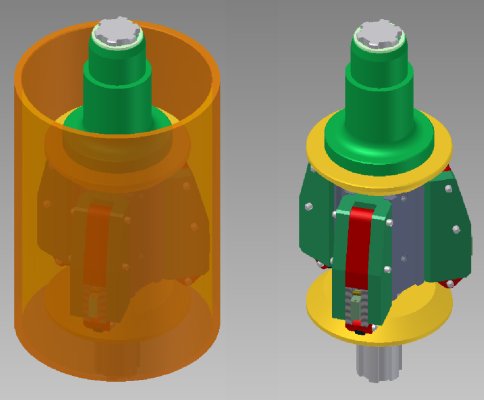

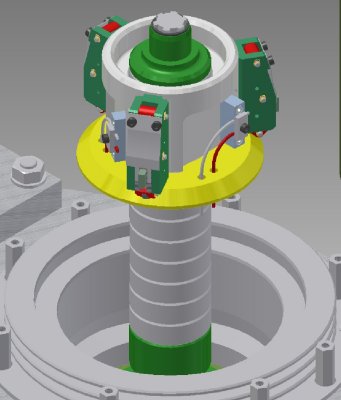

A complete (unmodified) cylinder liner sample is attached by means of an expanding collet to the test spindle. The lower end of the liner sample is supported by a steady bearing carried on a secondary cross-head. A spline shaft assembly, which mounts on the main cross-head, carries a ring sample carousel. The carousel is free to slide axially on, while its rotation is resisted by, the spline.

Large diameter liner in placeThe ring sample carousel has three locations for mounting ring samples, arranged on the same track level and at 120 degree intervals. Each ring sample is carried in a lever arm with a pivot point at one the upper end and a roller bearing at the lower, the latter engaging with a 45 degree cone, mounted on a spline shaft.

Ring carousel – small diameter liner

Ring carousel – large diameter liner

Ring carouselThe top of the assembly is loaded against a fixed bearing located in the expanding liner collet. The spline shaft is free to slide through the carousel assembly under axial load, forcing the cone against the lever arm bearings. Axial load on the carousel thus gives rise to equal radial load between the three ring samples and the liner, with a defined mechanical advantage.

The ring samples, which provide a straight line contact equivalent to a ring of infinite diameter, are carried in two dimensional spherical seats, allowing self-aligning action.

Tooling is custom designed to match the diameter of the liner specified by the user. The maximum permissible speed depends on the mass and inertia of the liner.Loading System

Load is applied to the main cross-head servo controlled pneumatic bellows actuator assembly which includes an in-line force transducer for measurement and feedback control of load.

Heating

The rotating cylinder liner is free to rotate within a heated enclosure. The heat source is PID controlled infra-red ceramic heating elements, with a pyrometer for measuring the outside surface temperature of the liner. Separate locations are provided for measuring the temperature of each ring sample.

Oil Feed and Drain

The carousel incorporates means for delivering lubricant, via hypodermic tubes, to each ring sample. A gallery is provided at the bottom of the spline shaft to collect discharged oil either for delivery to waste or for re-circulation.

Torque Measurement

The spline shaft assembly is dynamometer mounted in bearings with rotation resisted by a single force transducer, providing measurement of the combined torque generated by the three frictional contacts.

Positioning Cylinders

Pneumatic cylinders are provided for raising the main cross-head to insert the ring sample carousel assembly into the liner. Once in position, load bellows is put in position, specimen load is applied and the cylinders are disengaged from the cross-head.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Base Machine Rotational Speed: 2 to 2,000 rpm Motor: 4 kW ac @ 1500 rpm 50% overload available for 30 seconds Loading System: Pneumatic bellows Load Force: Strain gauge transducer x 1 Friction Torque: Strain gauge transducer x 1 Maximum liner temperature: 250°C Temperature Sensors: Optical pyrometer x 1 k-type thermocouple x 3 Interface: Serial Link Interface Module HSD High Speed Data Acquisition Card Software: COMPEND 2000 Small Liner Example Typical Ring Sample: Contact width: 10 mm Specimen thickness: 3 mm Contact crown radius: 25 mm Typical Cylinder Liner: Internal diameter: 83 mm External diameter: 90 mm Length: 130 mm Maximum Sample Load: 500 N Maximum Rotational Speed: 2,000 rpm Oscillating Motion: +/-10 degrees at 25 Hz +/-15 degrees at 20 Hz +/-20 degrees at 18 Hz +/-25 degrees at 15 Hz +/-35 degrees at 10 Hz +/-45 degrees at 8 Hz Large Liner Example Typical Ring Sample: Contact width: 20 mm Specimen thickness: 4 mm Contact crown radius: 50 mm Typical Cylinder Liner: Internal diameter: 170 mm External diameter: 193 mm Length: 370 mm Maximum Sample Load: 750 N Maximum Rotational Speed: 1,500 rpm Oscillating Motion: +/-10 degrees at 5 Hz +/-15 degrees at 4 Hz +/-20 degrees at 3 Hz +/-25 degrees at 2 Hz Controlled Parameters Rotational Speed Temperature Load Test Duration Recorded Parameters Rotational Speed Friction Torque Temperatures Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance Services Electricity: 380/415 V, three phase, 50/60 Hz, with neutral and earth, 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Installation Floor-standing machine: 900 mm x 600 mm deep x 2000 mm high, 250 kg Floor-standing cabinet: 600 mm x 600 mm x 1800 mm high, 150 kg Packing Specifications: 2.2 m3, GW 550 kg, NW 400 kg -

Overview Videos

-

Index Tags

bore polish boundary lubrication cylinder liner materials low speed pre-ignition multi-station piston ring materials ring and liner scuffing special applications -

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com