-

Background

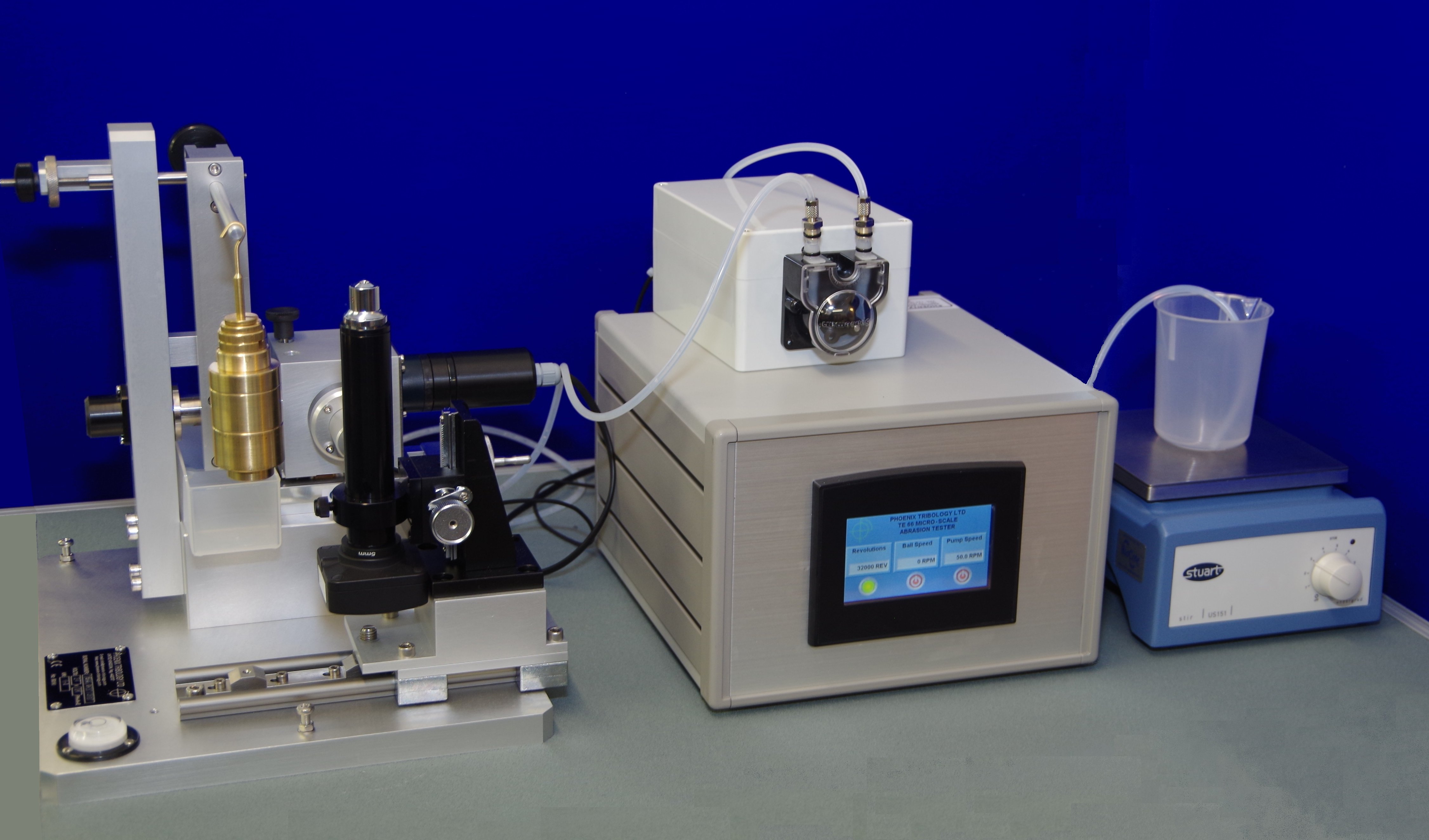

The TE 66 Micro-Scale Abrasion Tester is used for determining the wear coefficient of hard and soft coatings and monolithic materials by abrasive wear, in a ball on plate contact configuration. The machine may also be used as a crater-generating tool on coated surfaces for coating thickness determination. Tests can be performed in accordance with BS EN 1071-6: 2007: Advanced technical ceramics – Methods of test for ceramic coatings – Determination of the abrasion resistance of coatings by a micro-abrasion wear test.

Description

Other ball-cratering devices use a free ball that rests on the coated surface and at two points on a rotating shaft. The static load on the surface is determined by the size of the ball and the tilt angle of the coated surface. The ball is driven by friction against the shaft and abrasive slurry is fed into the wearing contact. As the ball is free and the friction conditions variable, the rotational speed, number of rotations and applied load are both uncertain.

In the TE 66 the ball is clamped into a rotating shaft and the test surface is mounted on a counterbalanced beam that hangs vertically from a pivot. This configuration offers the following advantages over the free ball:- • The load is defined precisely and without interaction with the friction force.

- • A wide range of loads can be applied, without the need for variable ball sizes.

- • Rotational speed of the ball and number of cycles completed is measured precisely.

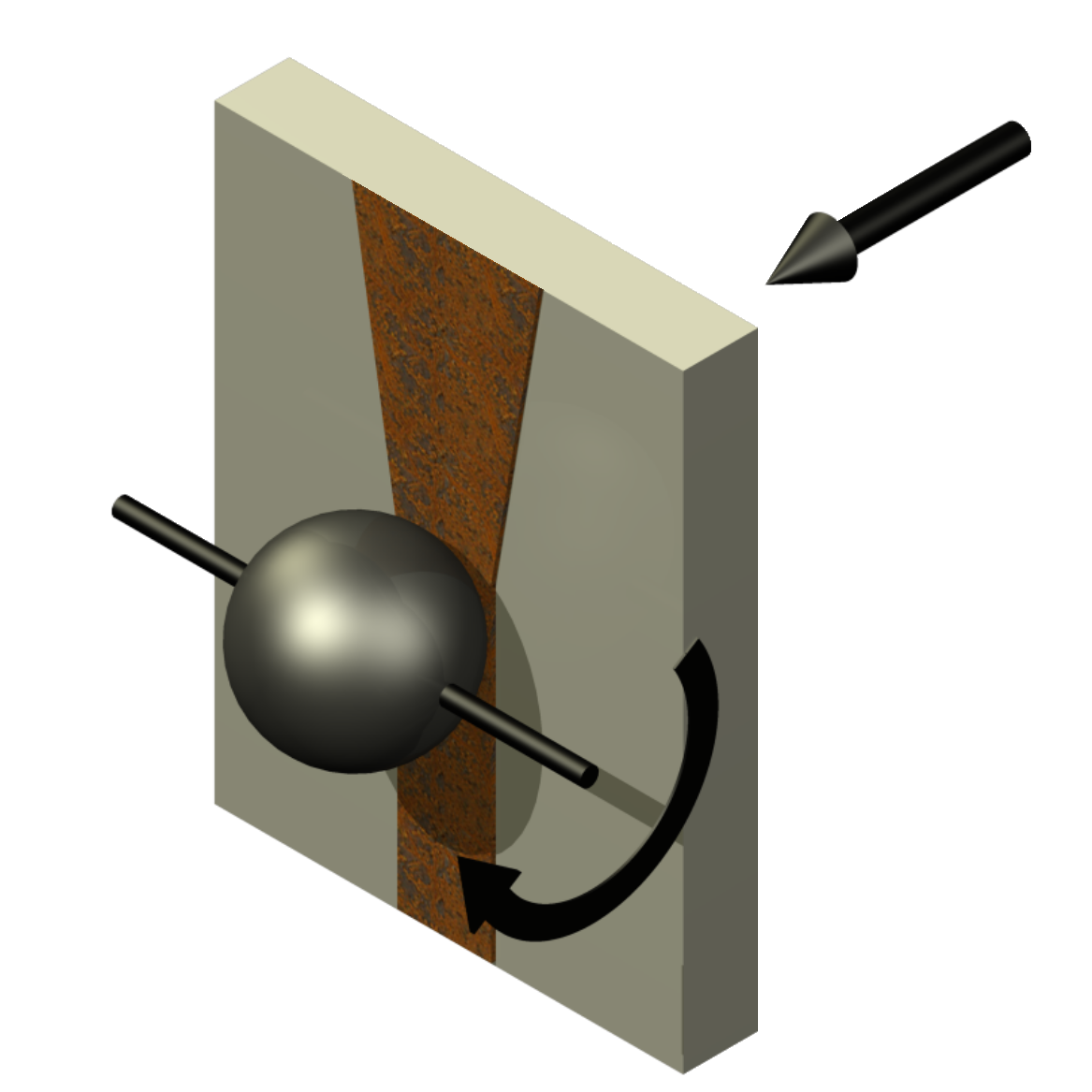

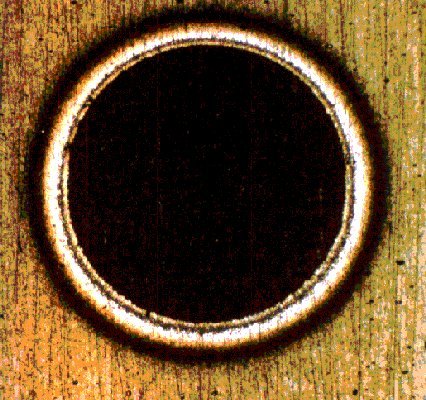

A 25 mm ball is clamped between two coaxial shafts each carried in support bearings. One shaft is driven by a variable speed dc geared motor. A batch counter is provided to measure and control the number of shaft revolutions.The rotation of a ball against a coated plate in the presence of an abrasive slurry results in the production of a circular depression. Eventually the coating is worn through and a “bulls-eye” depression is seen where the substrate shows through. Measurements of the inner and outer diameters of this bulls-eye are easily made and provide an accurate and low cost method of determining coating thickness. This is an established coating thickness measurement technique.

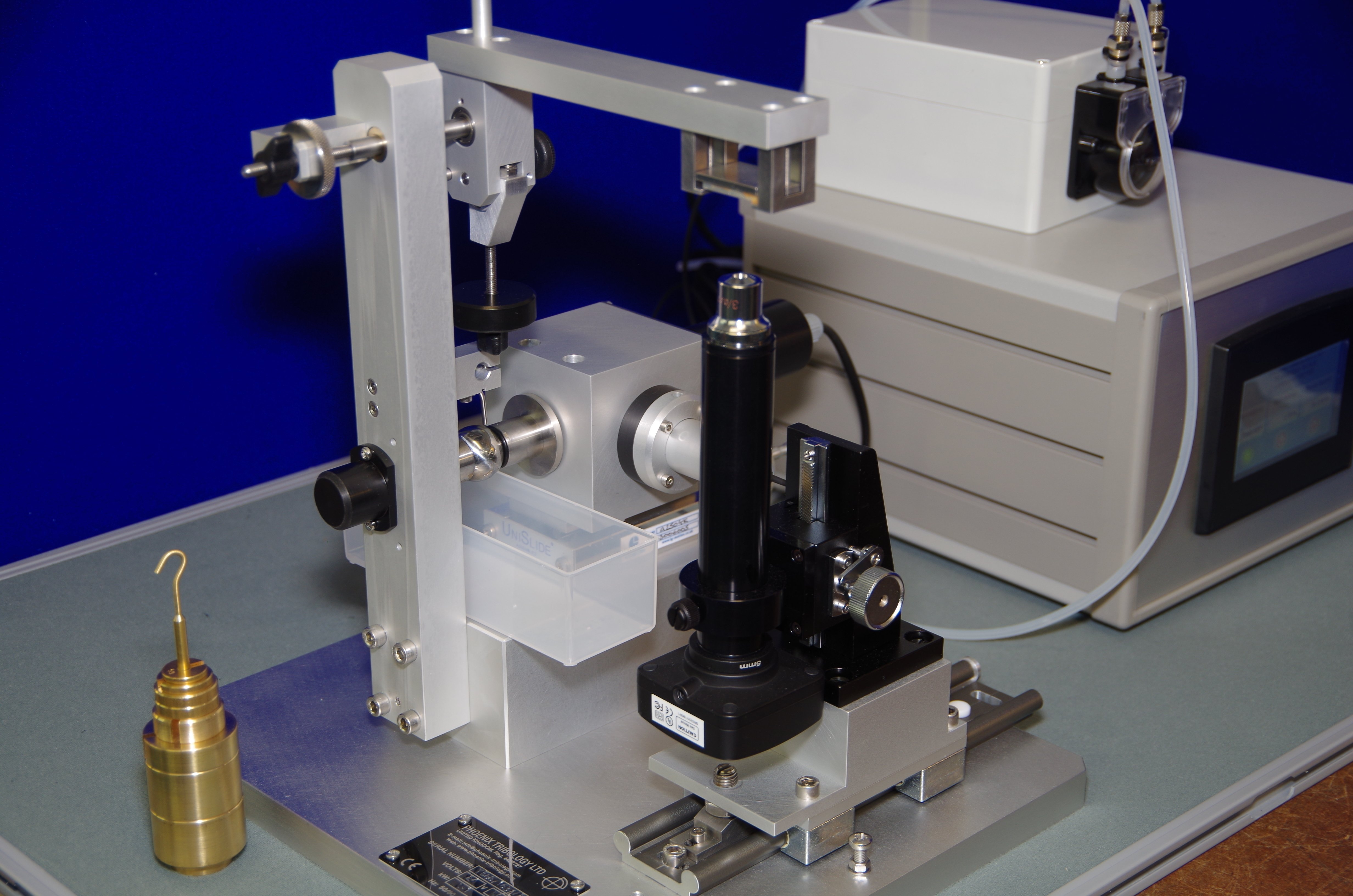

For wear coefficient determination, periodic measurement of wear is made, using an integral digital microscope. The crater is viewed by rotating the load arm to bring the sample out of contact with the ball, thus avoiding disturbance to the contact, by removal of the ball.

Slurry is stored in a container that can be agitated on a laboratory magnetic stirrer (available as option TE 66/S). A peristaltic pump is provided for pumping the slurry into the contact. It is fed to a position just above the contact point and collected in a waste tray underneath.

Control and Data Acquisition

Speed set-point control is manual, implemented via a PLC, with input via touch-screen. For periodic measurement of wear craters using the digital microscope, a PC is required.

TE 66/S Laboratory Magnetic Stirrer

Slurry is stored in a container that is agitated on the laboratory magnetic stirrer. The slurry is pumped by the integral peristaltic pump on the TE 66. It is fed to a position just above the contact point and collected in a waste tray underneath. 3 metres of pump tubing is provided with the TE 66/S.

TE 66/LC Line Contact Adapter

This item of tooling allows tests to be run with a line contact specimen in a non-conforming block on ring configuration. The tooling allows a disc specimen to be mounted in place of the standard ball specimen.

-

Technical Specifications

Ball Speed Range: 30 to 150 rpm Load Range: 0.05 to 5 N Ball Diameter: 25 mm Pump Feed Rate: up to 60 ml/hour Digital Camera: 5MP CMOS USB Camera Magnification: x3 and x5 TE 66/LC Line Contact Adapter Disc Diameter: 25 mm Disc Width: Up to 10 mm Services Electricity: 220/240V, single phase, 50 Hz, 120 W 110/120 V, single phase, 60 Hz, 120 W Installation Bench-mounting machine: 720 mm x 440 mm x 570 mm high, 15 kg Bench-mounting cabinet: 530 mm x 420 mm x 320 mm high, 10 kg Packing specifications: 0.21 m3, GW 50 kg, NW 25 kg -

Index Tags

-

Overview Videos

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com