-

Description

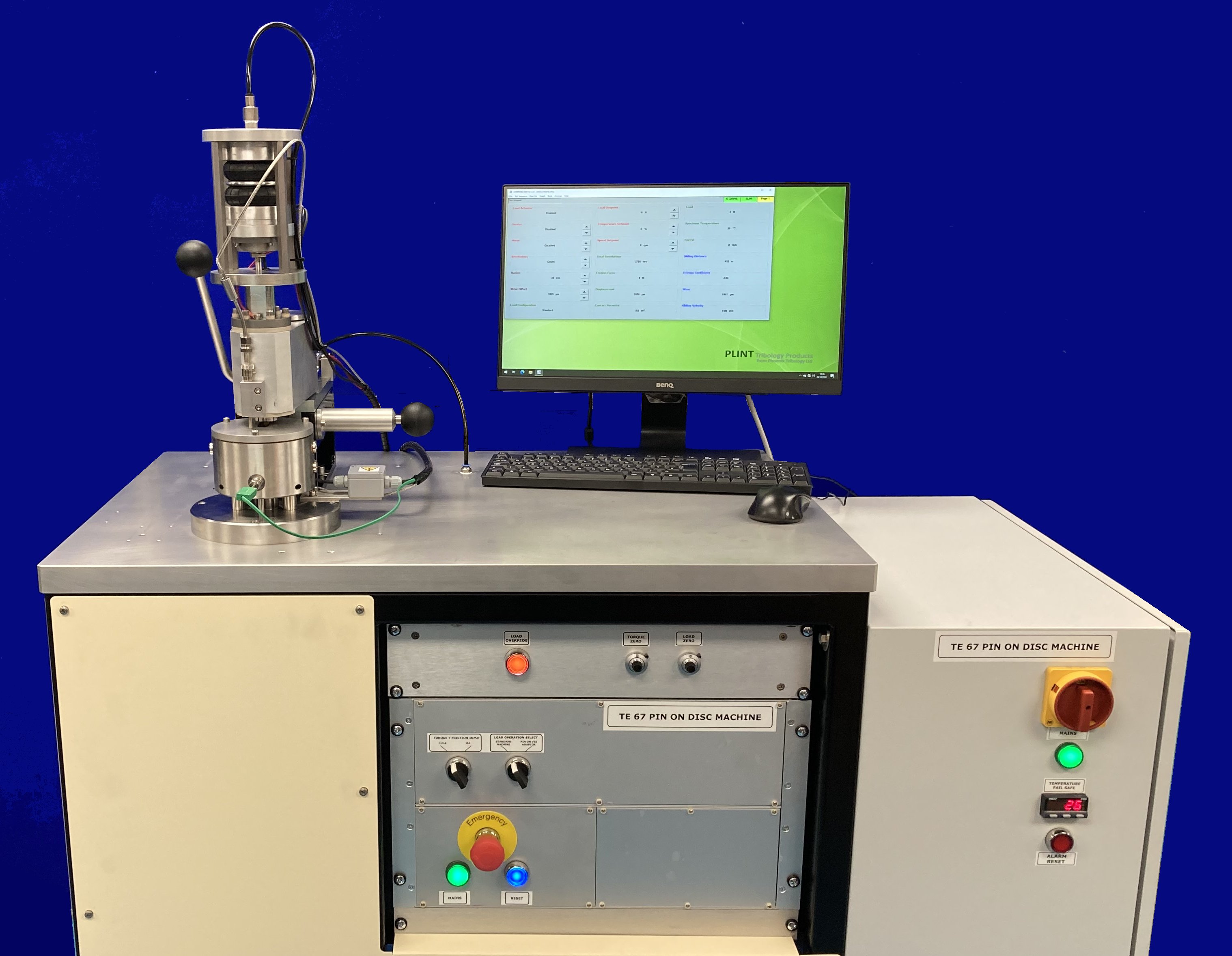

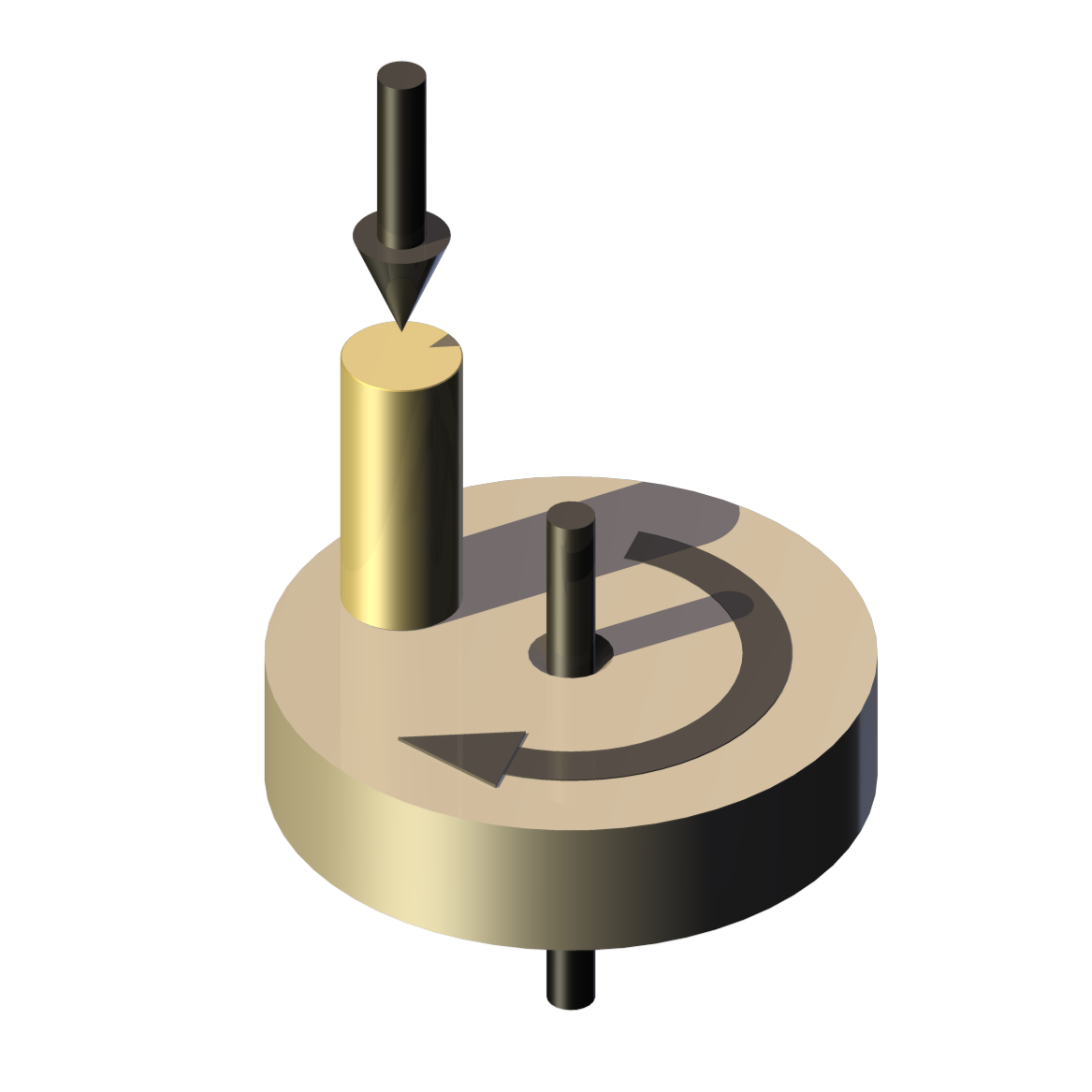

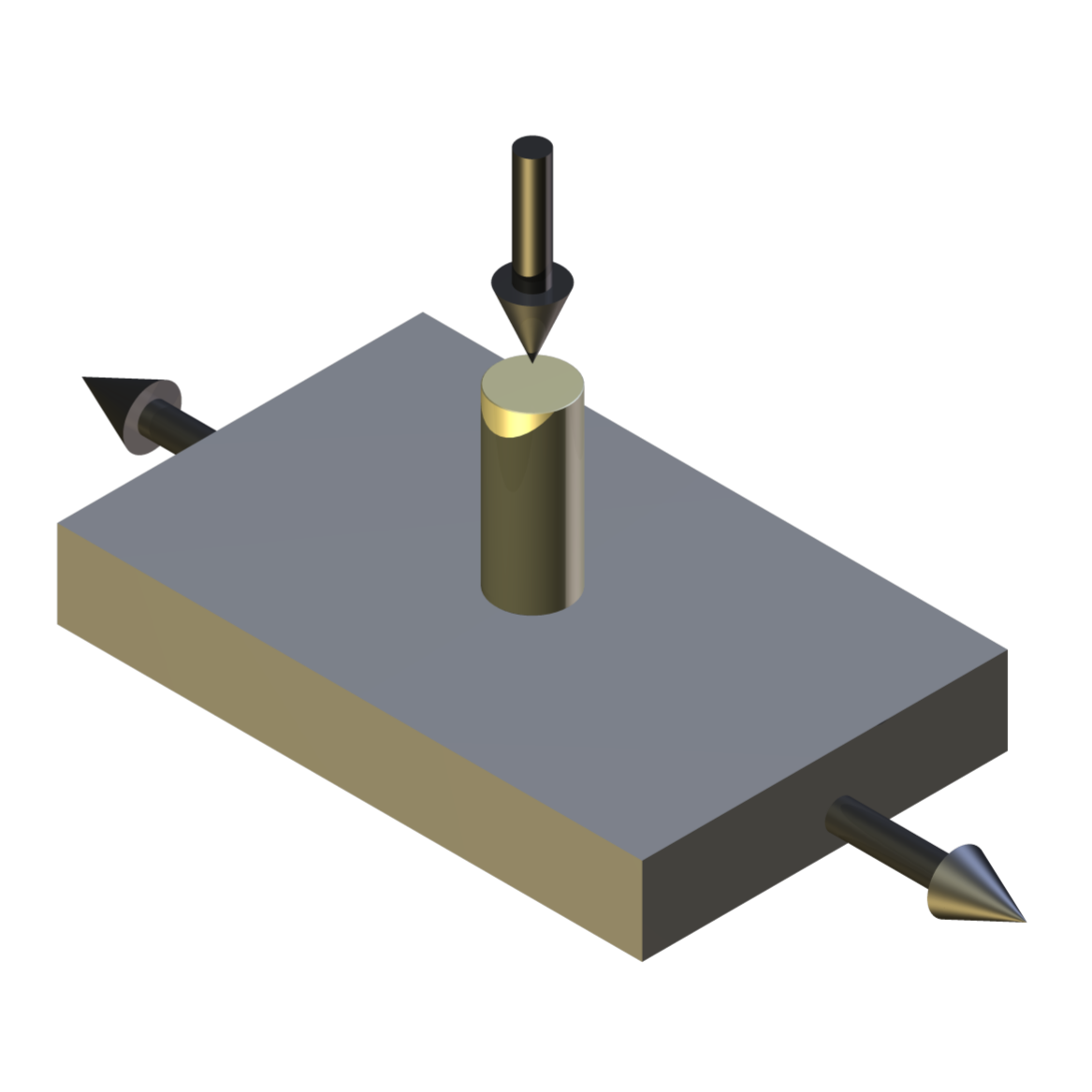

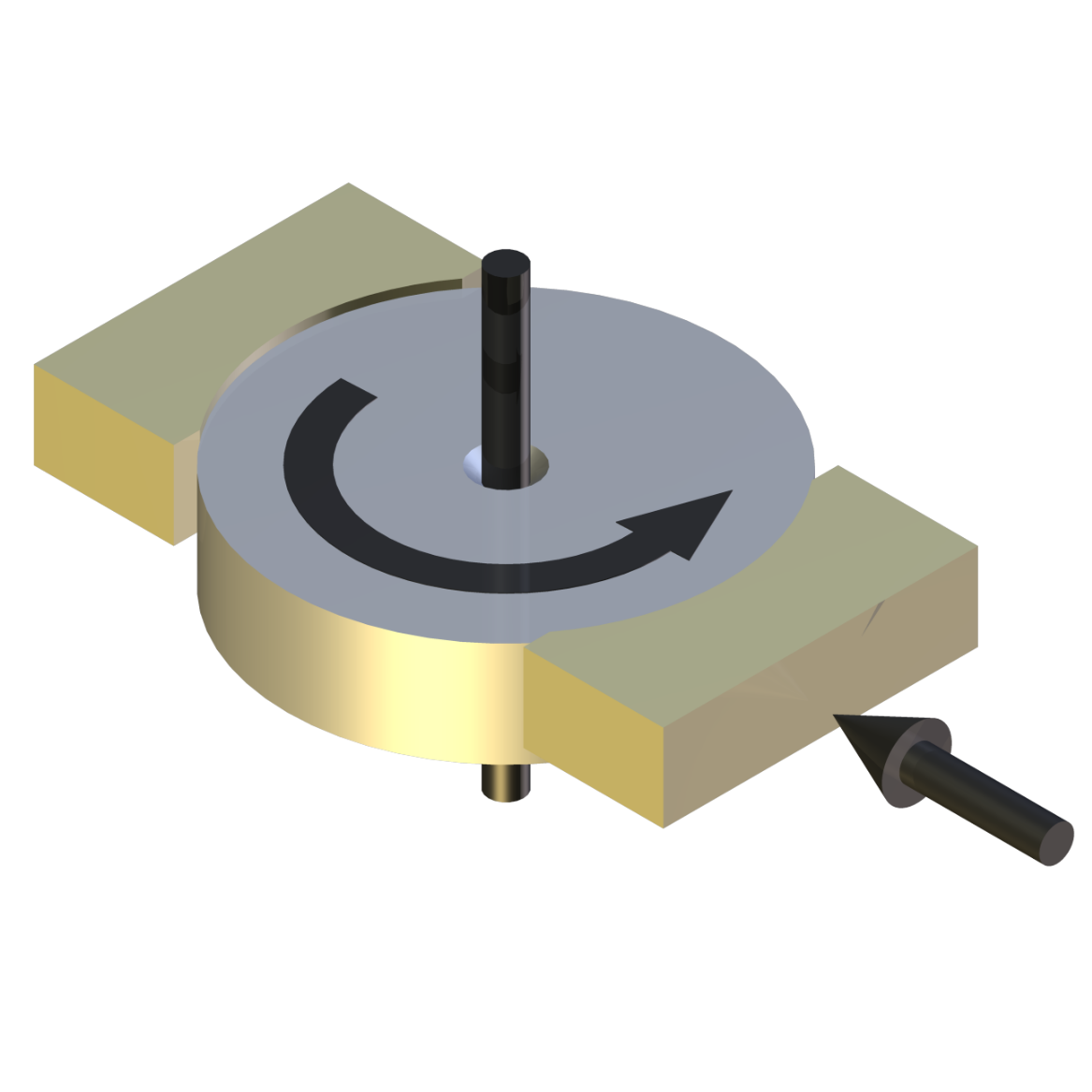

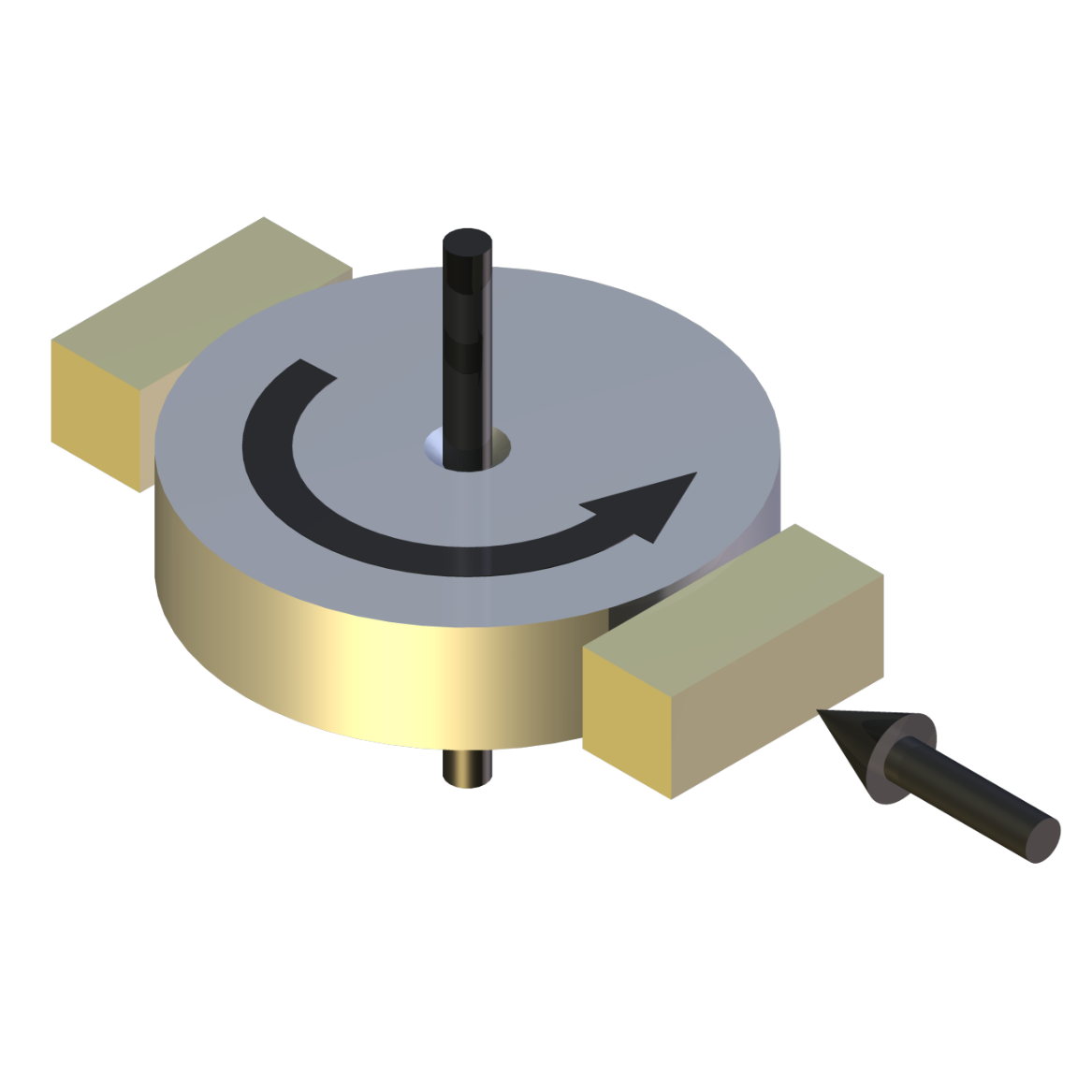

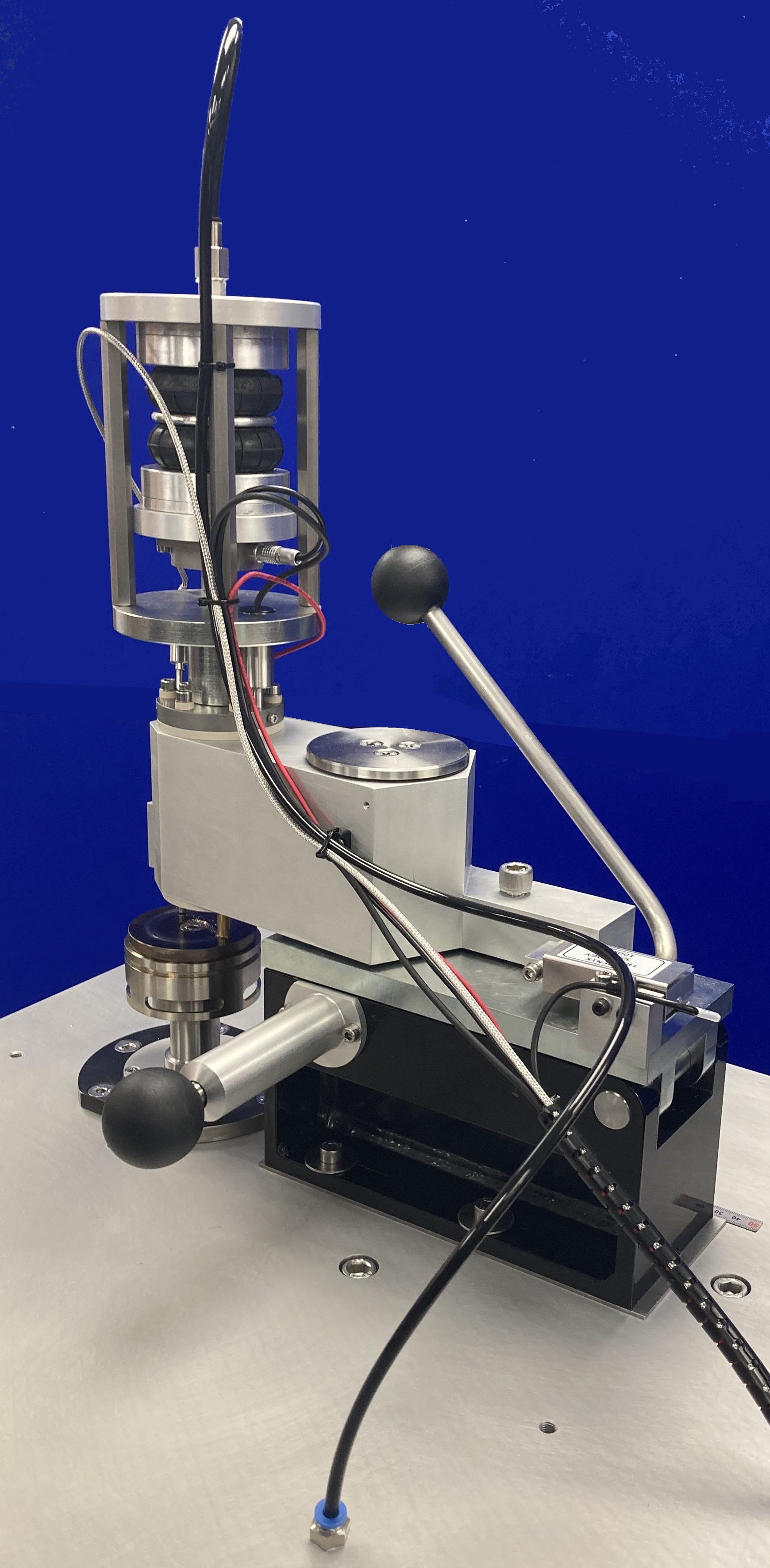

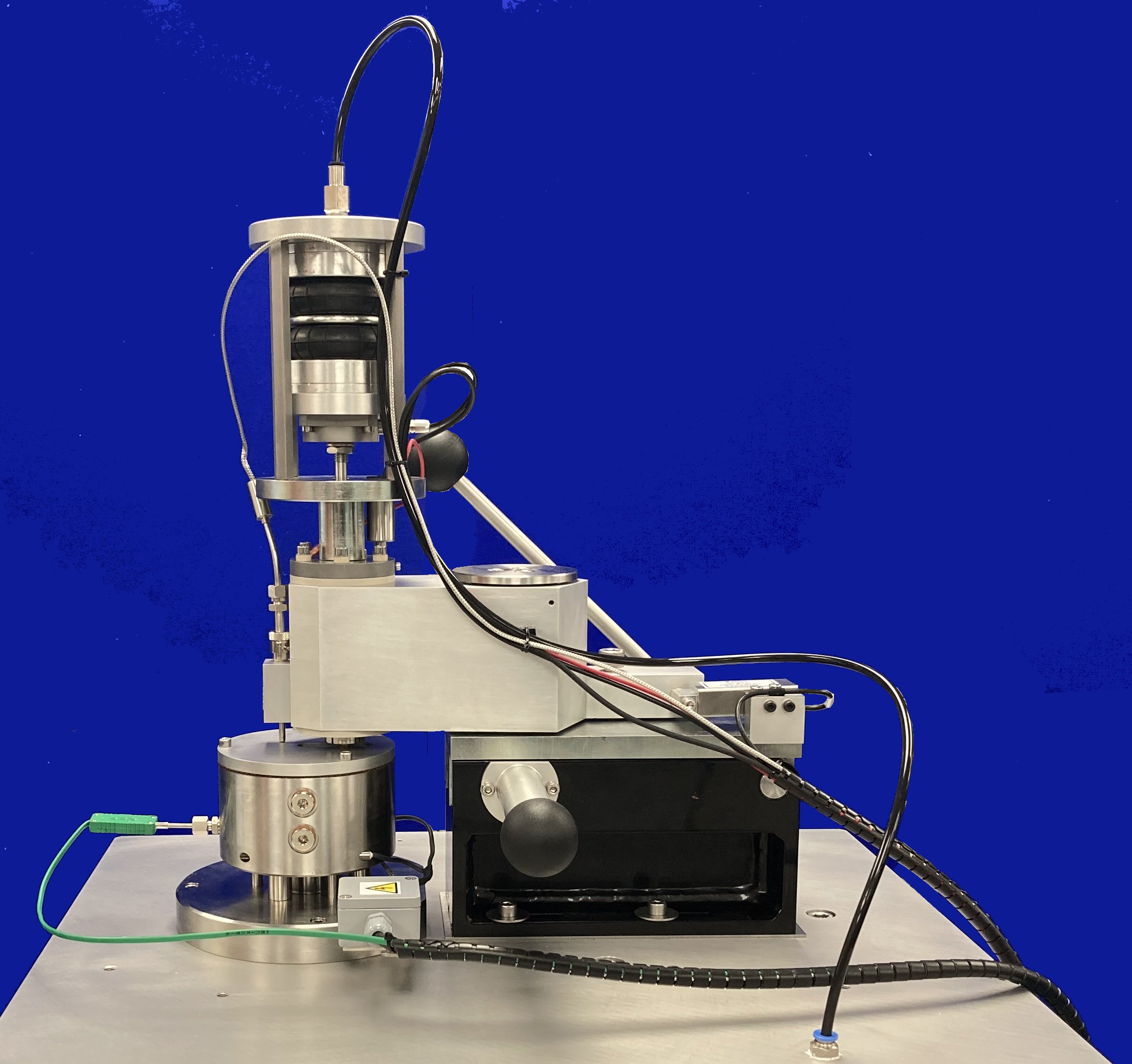

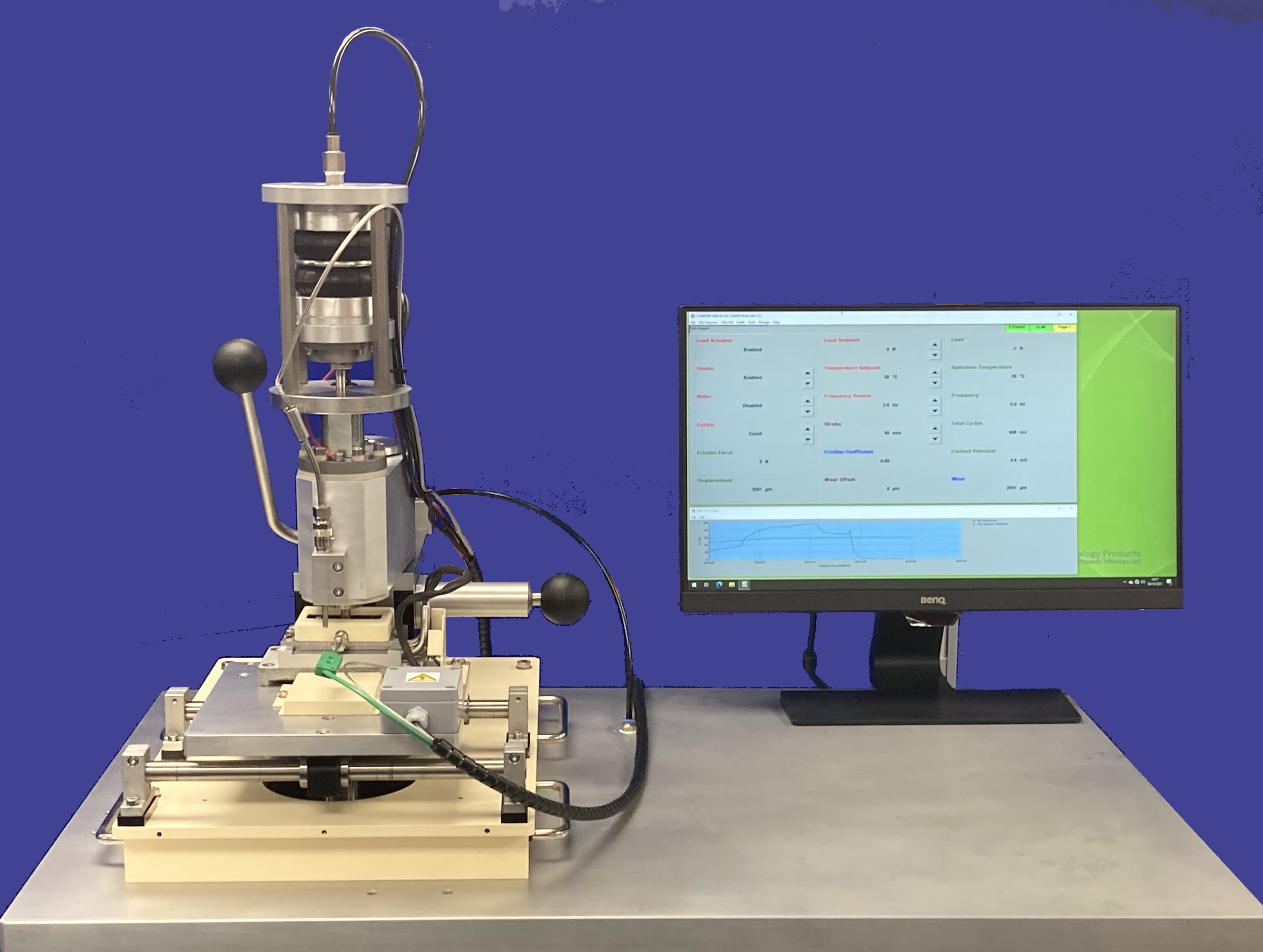

The TE 67 Pin on Disc Machine has the classic configuration of a pin or ball loaded vertically downwards onto a horizontally rotating disc. It also accommodates a variety of other test geometries.

The principle features of the unit are:• very rigid pin and disc carriers, to allow nominally flat-on-flat contact

• use of pneumatic loading on the pin to reduce inertial loading effects in the contactThe pneumatic loading system is an important difference with other pin on disc designs that use dead weights and a load beam. Loading system inertia can significantly affect the friction and wear response.

The test disc is mounted on the machine spindle driven by a vector controlled a.c. motor. Encoder feedback ensures stable running speeds and a large turn-down ratio.

The pin carrier assembly consists of an aluminium block pivoted about a vertical axis through its centre. The track radius is set by moving the pin carrier assembly radially.

A strain gauge load cell is mounted at the rear of the pin carrier block, preventing the block pivoting about its axis, hence sensing the friction force on the pin. The low rotational inertia of the carrier block about this axis ensures a good signal bandwidth for the friction measurement.

The pin carrier assembly can be rotated out of its locked horizontal position to allow access for changing specimens and examining the surfaces.

The test pin is inserted into a collet clamp on the loading piston. An in-line load cell measures the applied load and provides feedback for pneumatic load control. Both steady and fluctuating loads can be applied.

Movement of the loading piston is measured with an LVDT as an indication of wear.

The pin loading capsule is electrically isolated from the carrier block and a slip-ring is provide on the machine spindle, allowing measurement of contact potential, via a Lunn-Furey circuit.

A sliding contact thermocouple is used to sense disc temperature.

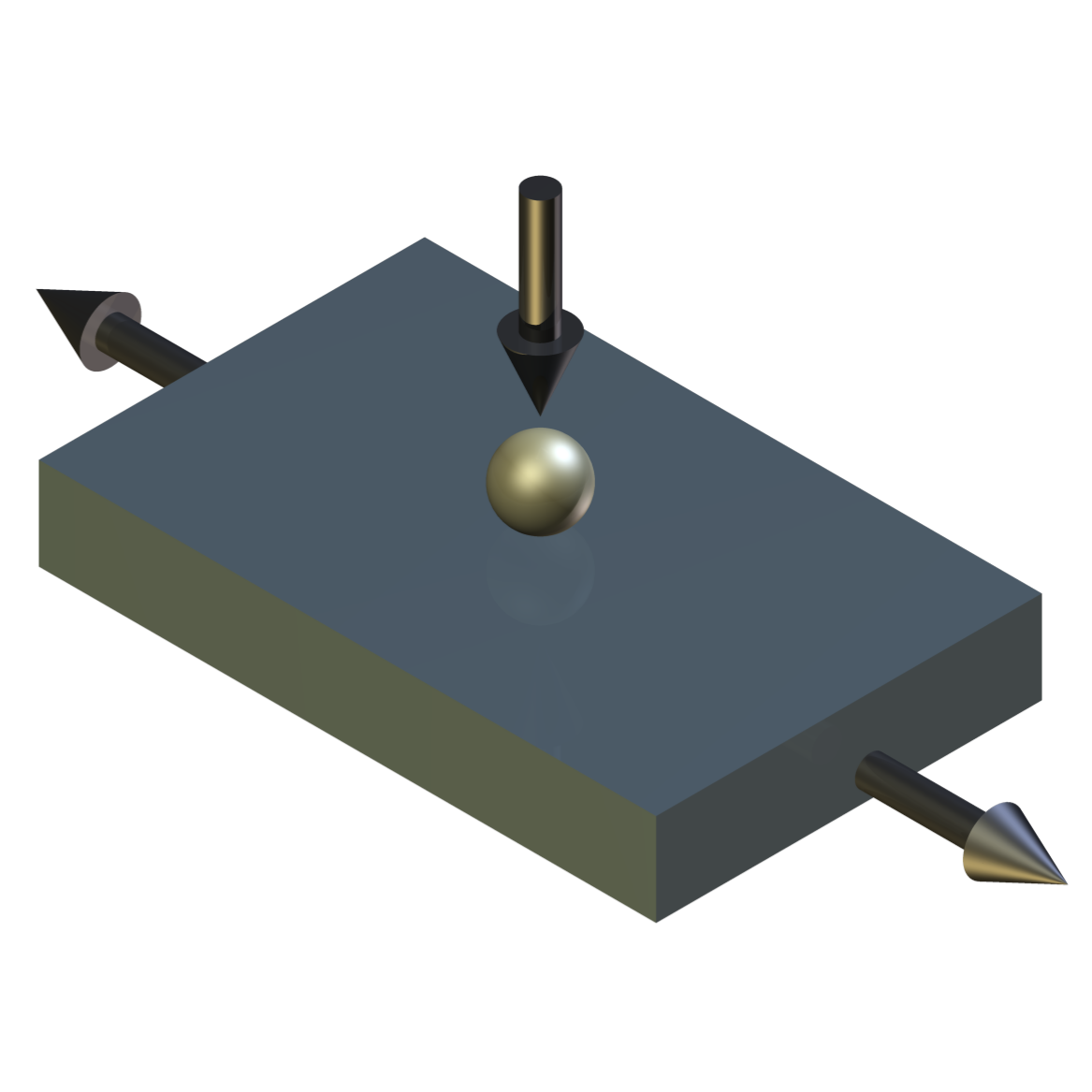

Test may be run in pin/ball on disc mode according to the guidelines laid out in ASTM G99, DIN 50324 and ISO/DIS 7148-2 and in reciprocating mode according to ASTM F732.

COMPEND 2000 control and data acquisition software, in conjunction with Phoenix Tribology’s own USB interface module, provides automatic control of load, speed, temperature and test duration, combined with data logging of all measured parameters.Pin on Disc Accessories

TE 67/LE Lubricant Enclosure

This is a heated, non-rotating, fluid bath for lubricated tests at temperatures up to 200°C.

TE 67/HT Pin on Disc Heating – Hot Air

This is a hot air gun system for dry tests at temperatures up to 400°C.

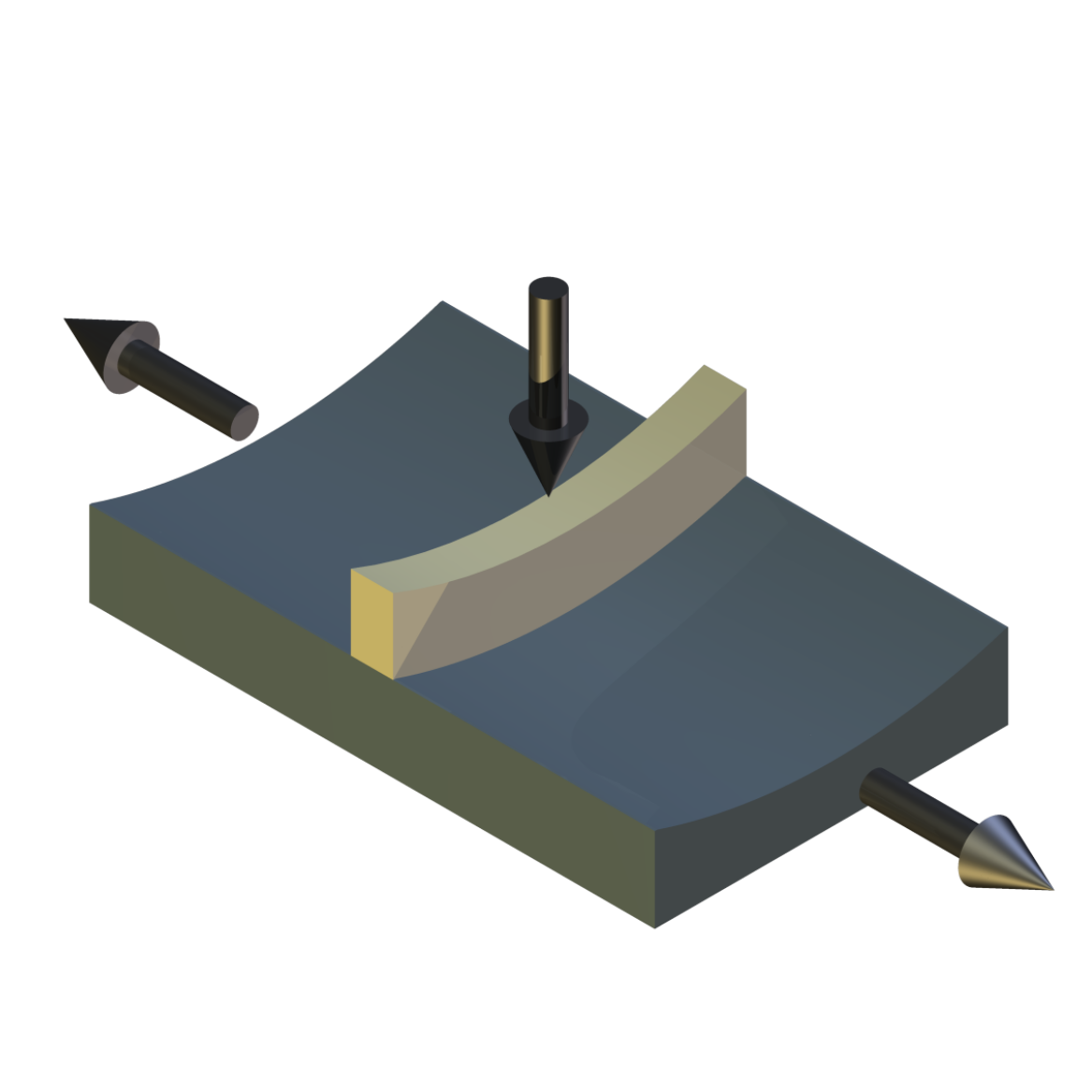

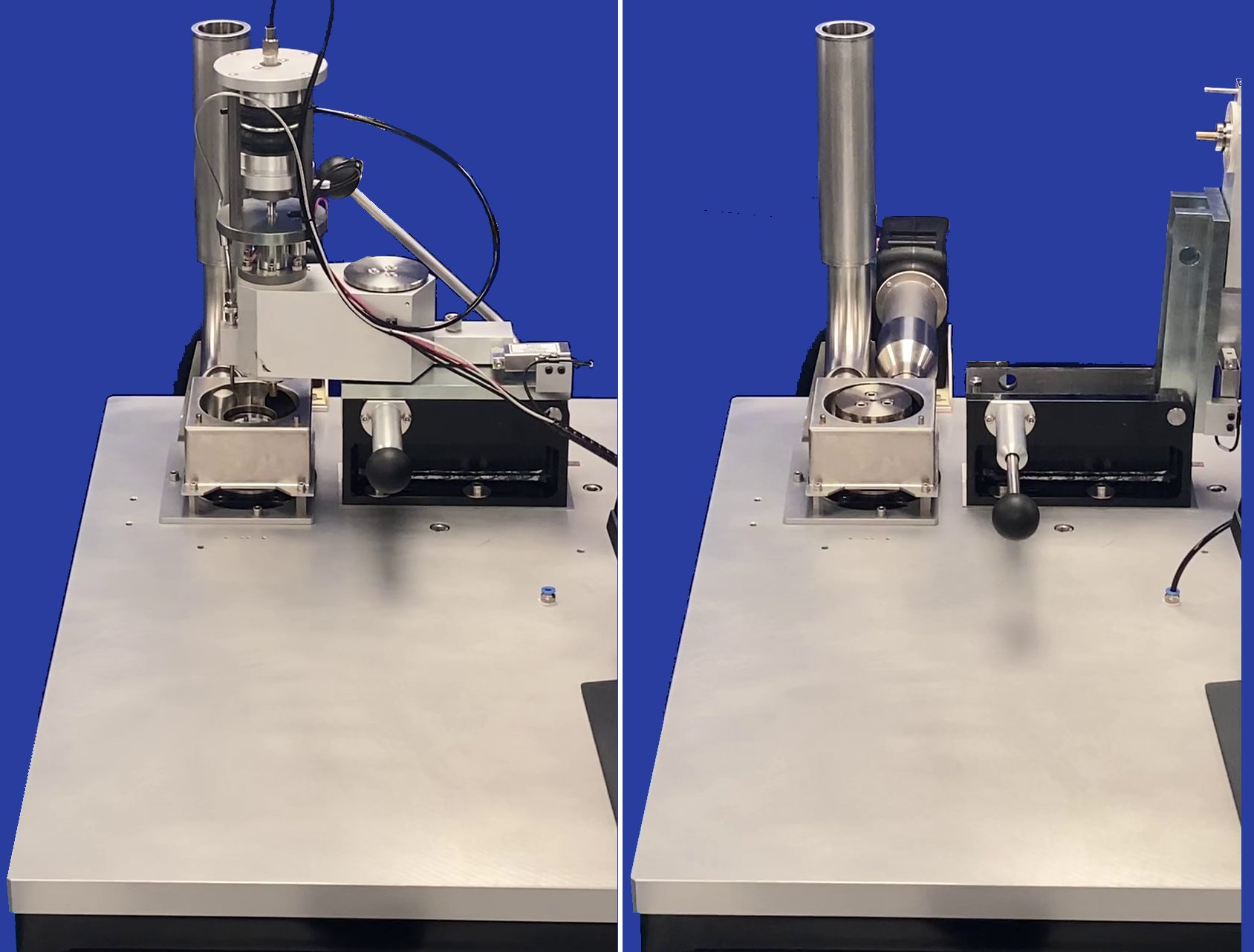

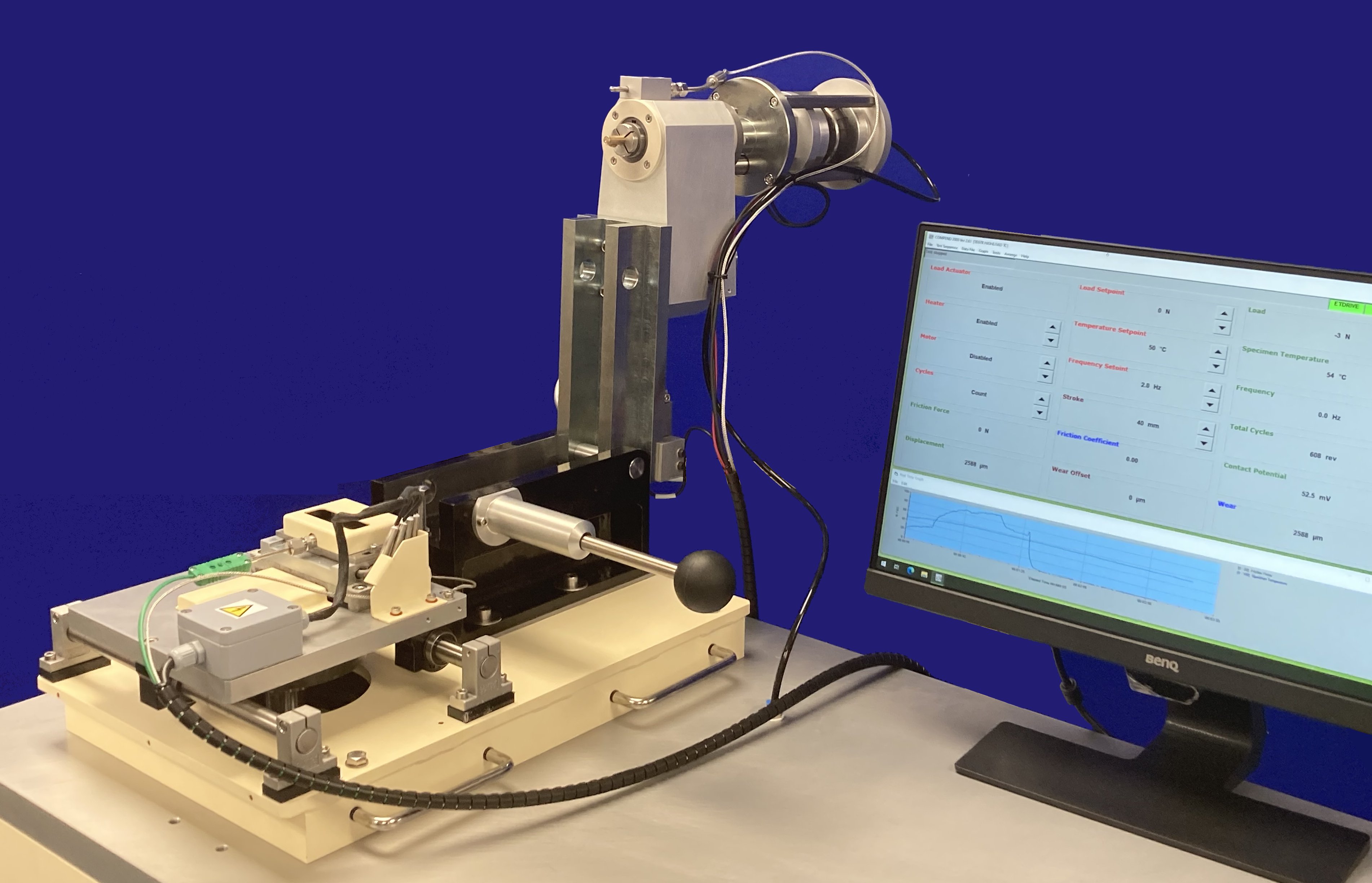

TE 67/R Reciprocating Pin on Plate Adapter

The adapter is a complete sub-assembly that mounts on top of the drive spindle. Sinusoidal reciprocating motion is generated by a scotch yoke mechanism that can be adjusted to give strokes from 0 to 50 mm. The maximum frequency at 50 mm stroke is 5 Hz. Higher frequencies can be achieved at shorter strokes. Integral heaters allow tests to be run at temperatures up to 400°C.

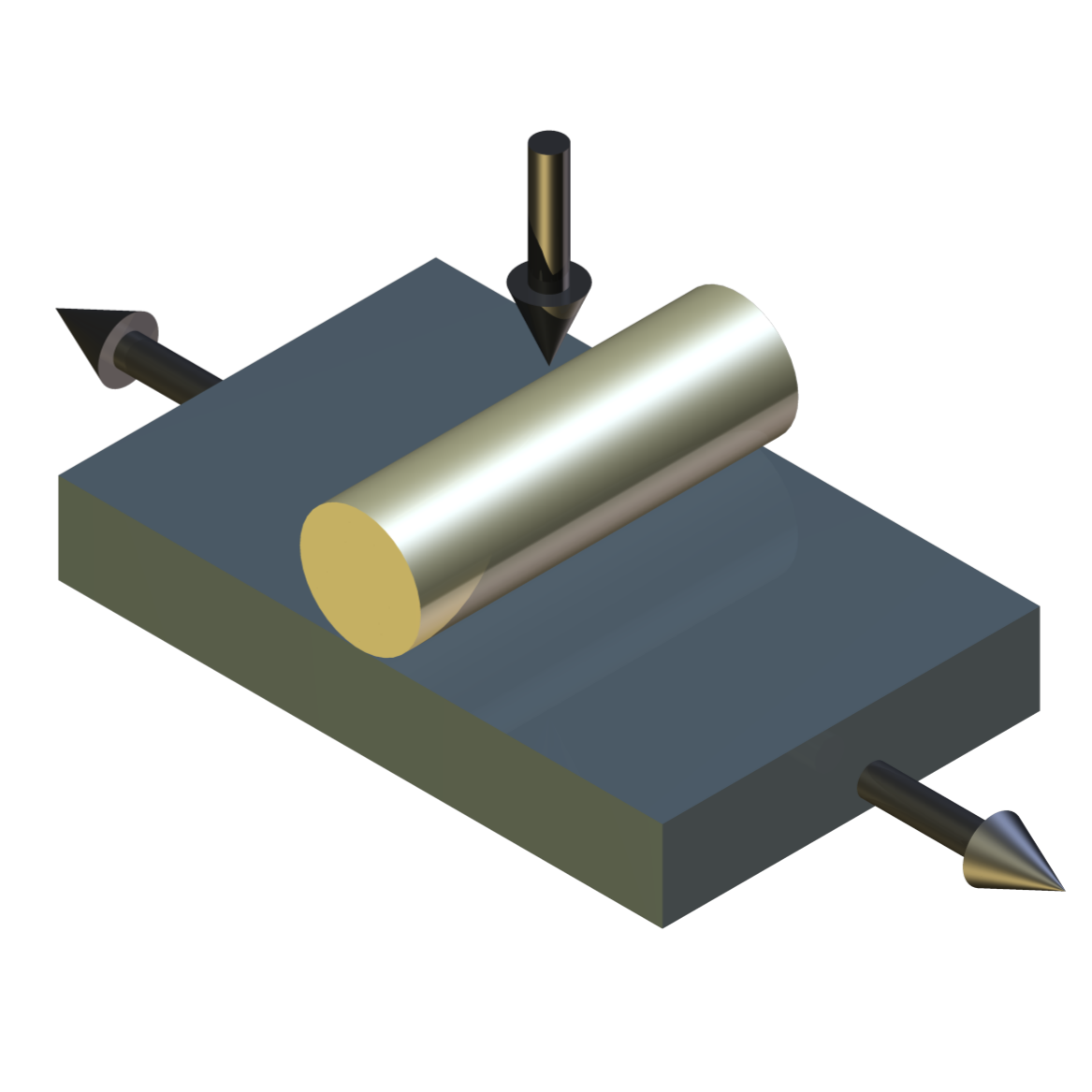

TE 67/LCA Line Contact Adapter

This is a sample holder for running line contact and piston ring and cylinder liner samples on the TE 67/R. It incorporates a self-alignment mechanism to ensure uniform contact.

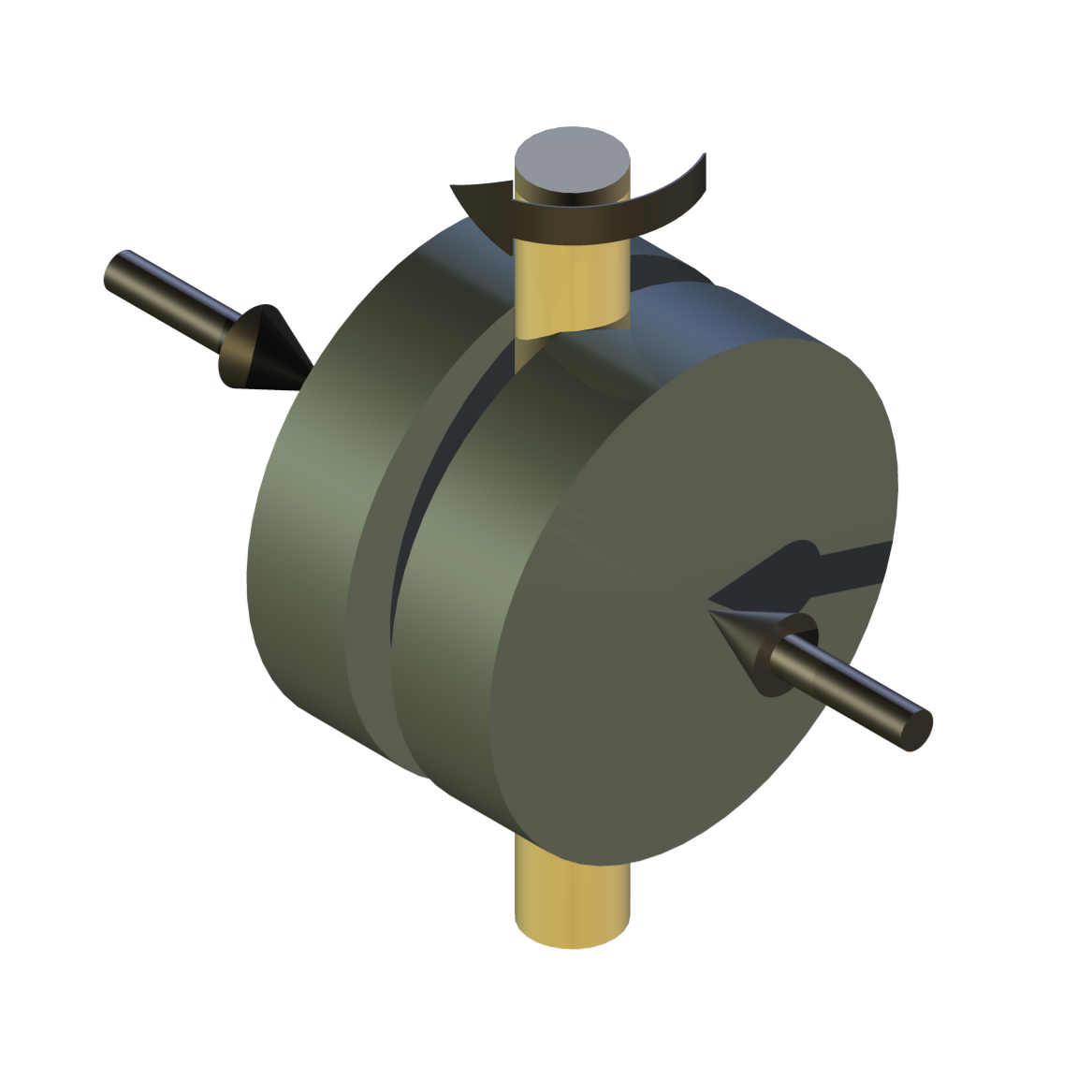

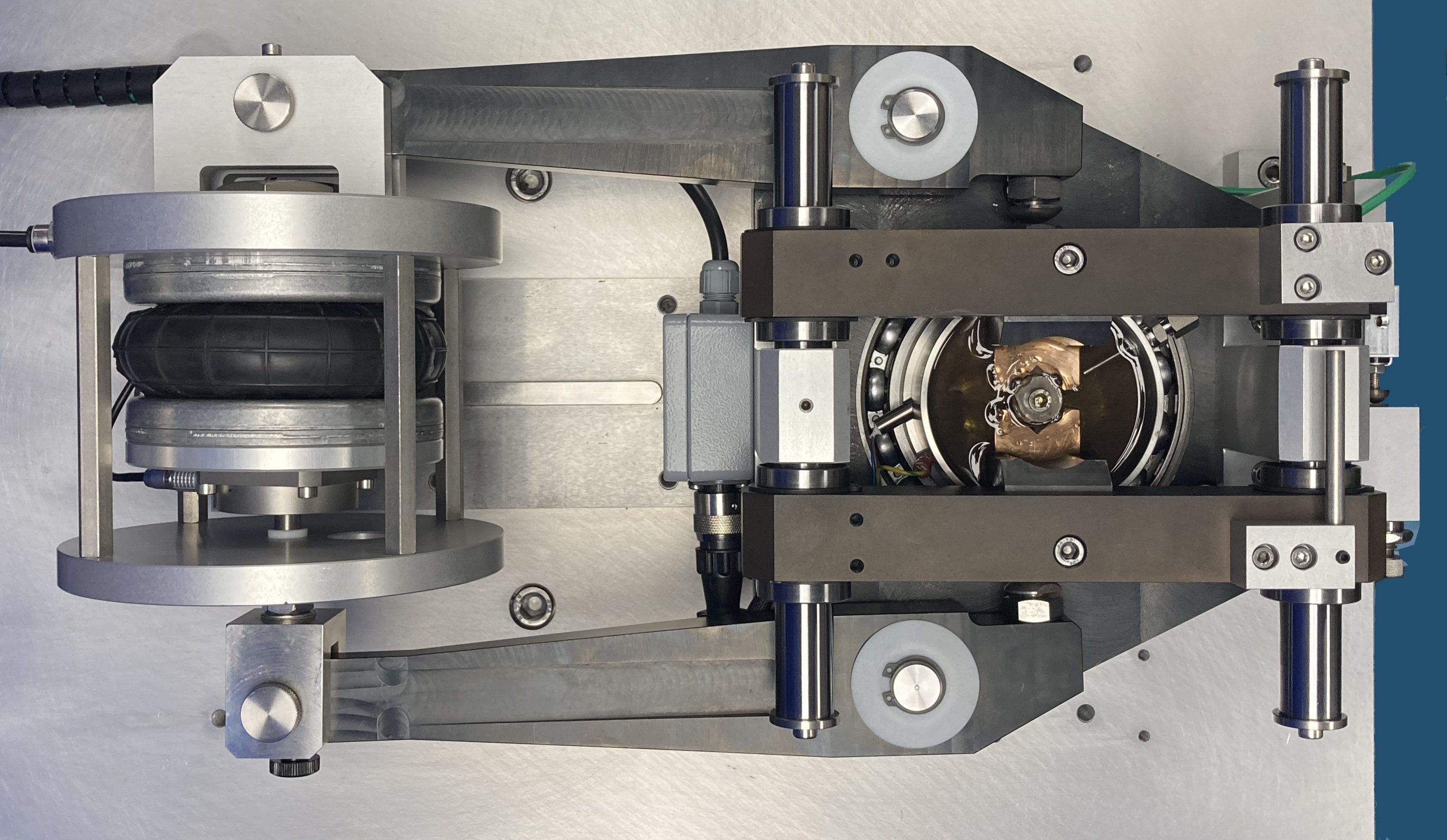

TE 67/PV Pin on Vee Block/Block on Ring Adapter

The Pin on Vee Block/Block on Ring Adapter allows test to be run in pin on vee block test geometry and the twin block on ring geometry, with a test specimen loaded on either side of a rotating ring. The block specimens may either be flat or conforming, allowing journal bearing type tests to be performed.

TE 67/CAL Calibration Kit for Load and Friction

TE 67/CAL provides a pivoted beam with dead weights able to apply up to 1,000 N to the loading system and a pulley, cord and weights to apply a tangential force to the pin carrier for friction measurement.

-

Technical Specifications

Rotational Speed: 20 to 2,000 rpm Equivalent Sliding Speed: 0.05 m/s to 8 m/s Radius of Test Track: 0 to 35 mm Pneumatic Loading Capsule: Load Range: 25 to 1000 N Cyclic Loading Amplitude: up to 50% of setpoint Cyclic Loading Type: sine wave or triangular wave Cyclic Loading Rate: 1 Hz maximum Dead Weight Loading Capsule: Load Range: 5 to 100 N Friction Force: 0 to 50 N and 0 to 1,000 N Wear Measurement: LVDT 0 to 2.5 mm Resolution better than 1 µm Contact Potential: 40 mV dc signal Temperature Sensing: k-type thermocouples Disc Specimen: 75 mm diameter x 8 mm thick Pin Specimen: 8 mm diameter x 35 to 68 mm long Ball Specimen: 6 mm diameter Interface: Serial Link Interface Module Software: COMPEND 2000 Motor: 2.2 kW ac vector Controlled Parameters Rotational Speed Temperature Load Test Duration Recorded Parameters Rotational Speed Wear Friction Force Temperatures Contact Potential Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance TE 67/HT Pin on Disc Heating (Air) Lubricated Tests: up to 200°C Dry Tests: up to 400°C by air Air Heating Power: 2.8 kW Temperature sensing: Optical Pyrometer with k-type thermocouple output TE 67/R Reciprocating Plate Adapter Stroke: 0 to 50 mm (continuous variation) Frequency: 2 to 25 Hz 5 Hz max. at 50 mm stroke 25 Hz max. at 2 mm stroke Heating Power: 800 W Temperature: ambient to 400°C Plate Dimensions: 38 mm x 58 mm x 4 mm thick TE 67/LE Lubricant Enclosure Bath Volume: 150 ml Heating Power: 400 W Temperature Range: ambient to 200°C TE 67/LS Lubricant Recirculating System Bath Volume: 1.2 litres Peristaltic Pump Flow: 1 litre/minute (maximum) Heating Power: 550 W Temperature Range: ambient to 100°C TE 67/PV Pin on Vee Block/Block on Ring Adapter Contact Configuration: Pin on vee block Block on ring Conforming block on ring Pin on Vee Specimens: Standard Falex specimens Ring Specimen: Max diameter 35 mm x max width 10 mm Maximum Load: 20,000 N Heater Bath Temperature: 200°C Services Electricity: 220/240V, single phase, 50 Hz, 7.5 kW 110/120 V, single phase, 60 Hz, 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) TE 67/HT2: Propane with 4 bar regulator 340 g/hour gas consumption Installation Floor-standing machine: 900 mm wide x 600 mm deep x 1,200 mm high, 300 kg Bench-mounting cabinet: 530 mm x 800 mm x 300 mm high, 20 kg Packing Specifications: 1.93 m3, GW 520 kg, NW 380 kg -

Machine Overview

-

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com