-

Description

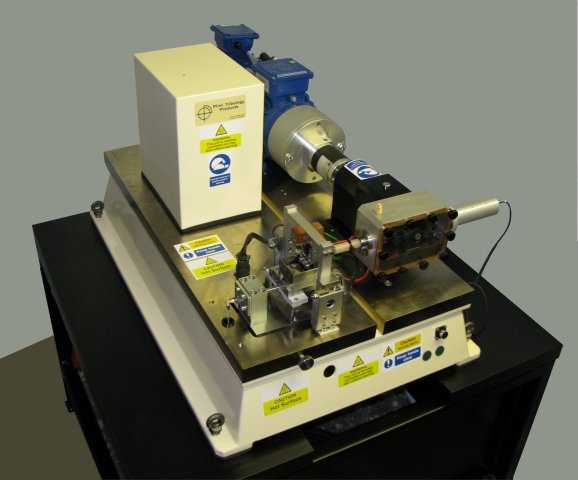

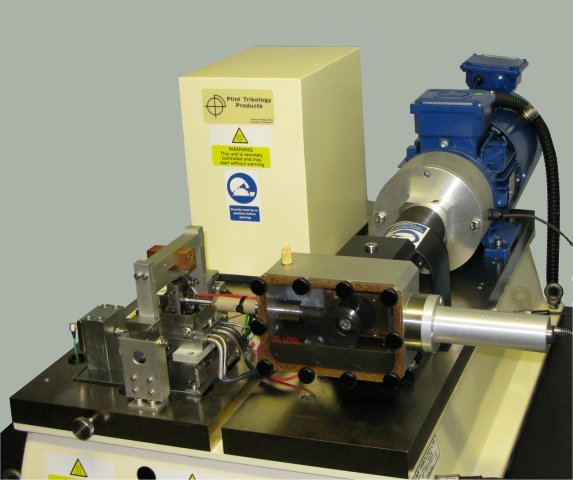

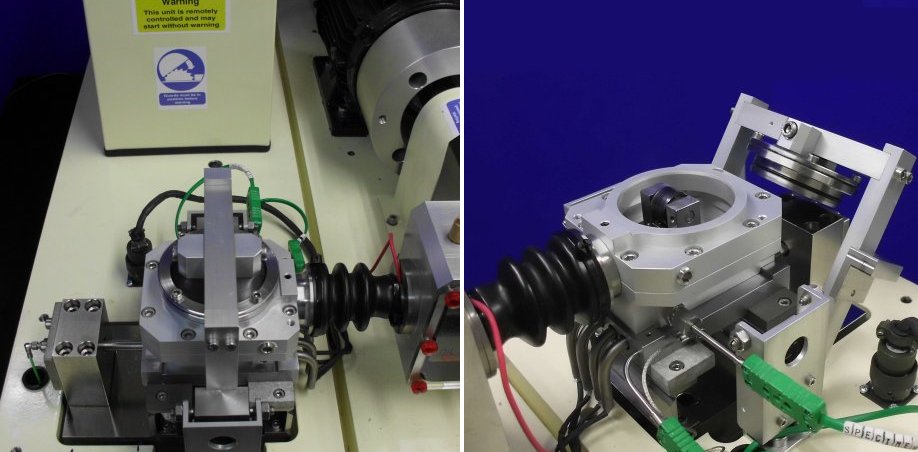

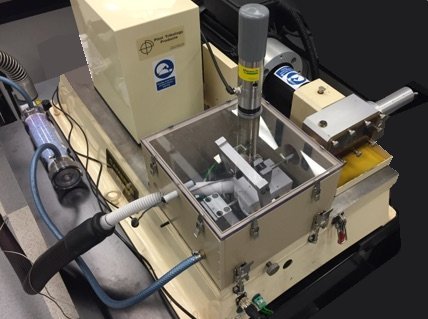

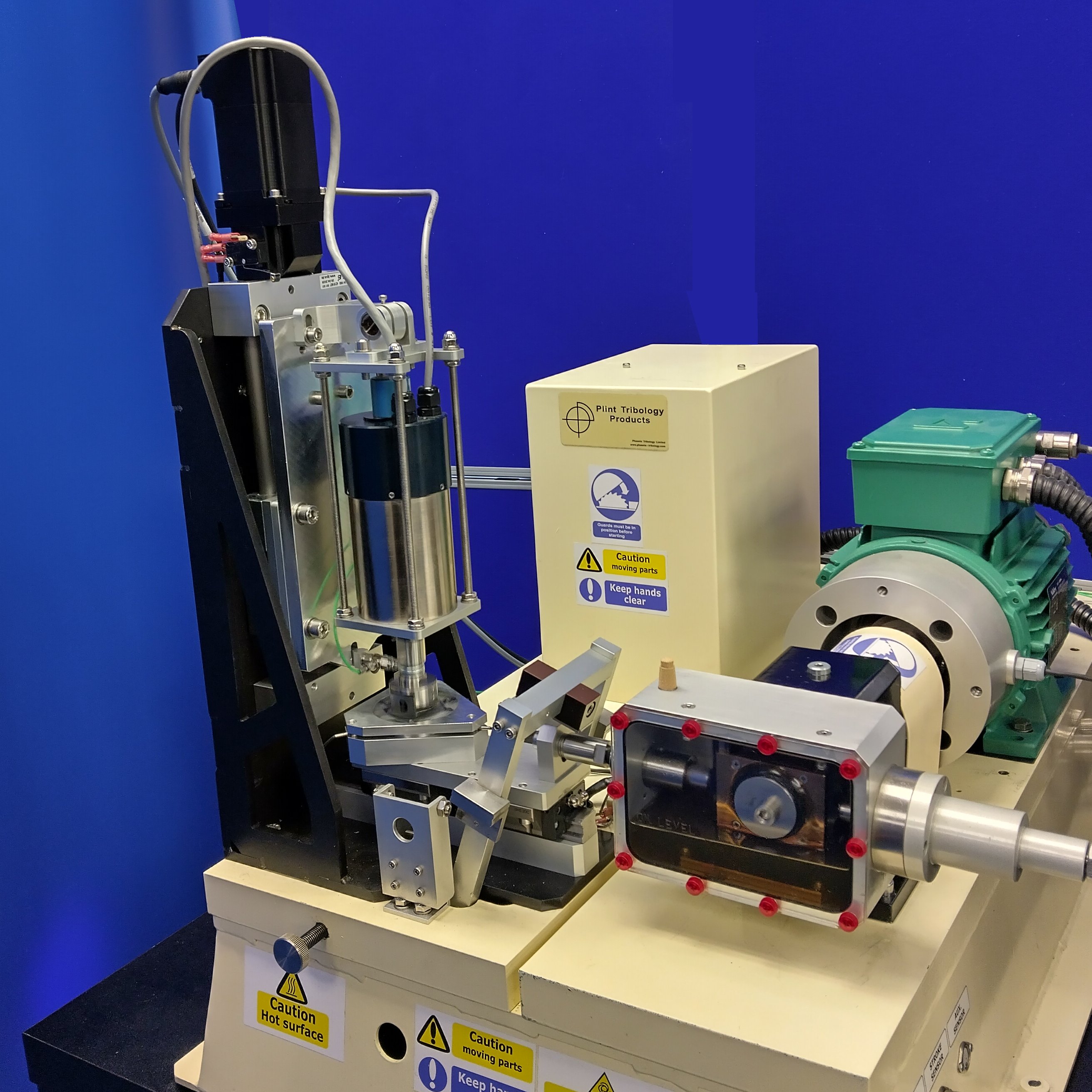

The TE 77 High Frequency Friction Machine is reciprocating tribometer with a maximum stroke of 25 mm and maximum load of 1,000 N. It was used for the inter laboratory tests for the development of ASTM G 133 “Standard Test Method for Linearly Reciprocating Ball on Flat Sliding Wear”, which addresses the dry and lubricated wear of ceramics, metals and ceramic composites, and also for ASTM G 181 “Standard Practice for Conducting Friction Tests of Piston Ring and Cylinder Liner Materials Under Lubricated Conditions”.

The machine is floor standing with integral control unit incorporating a Phoenix Tribology USB Serial Link Interface Module. This is connected to a PC with COMPEND 2000 sequence control and data acquisition software installed. The system provides sequence control of load, frequency and temperature plus data acquisition of measured parameters, at both low and high speed.

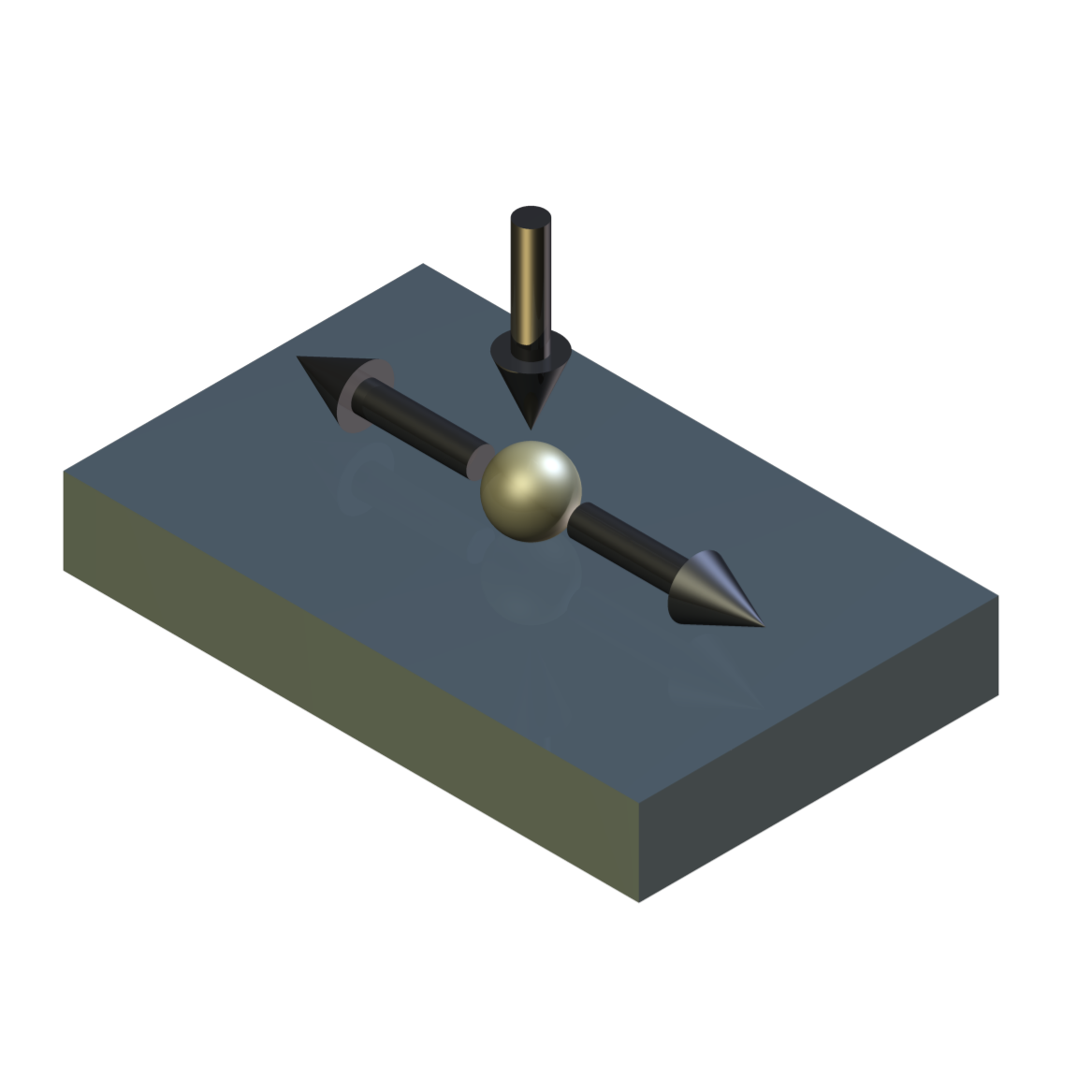

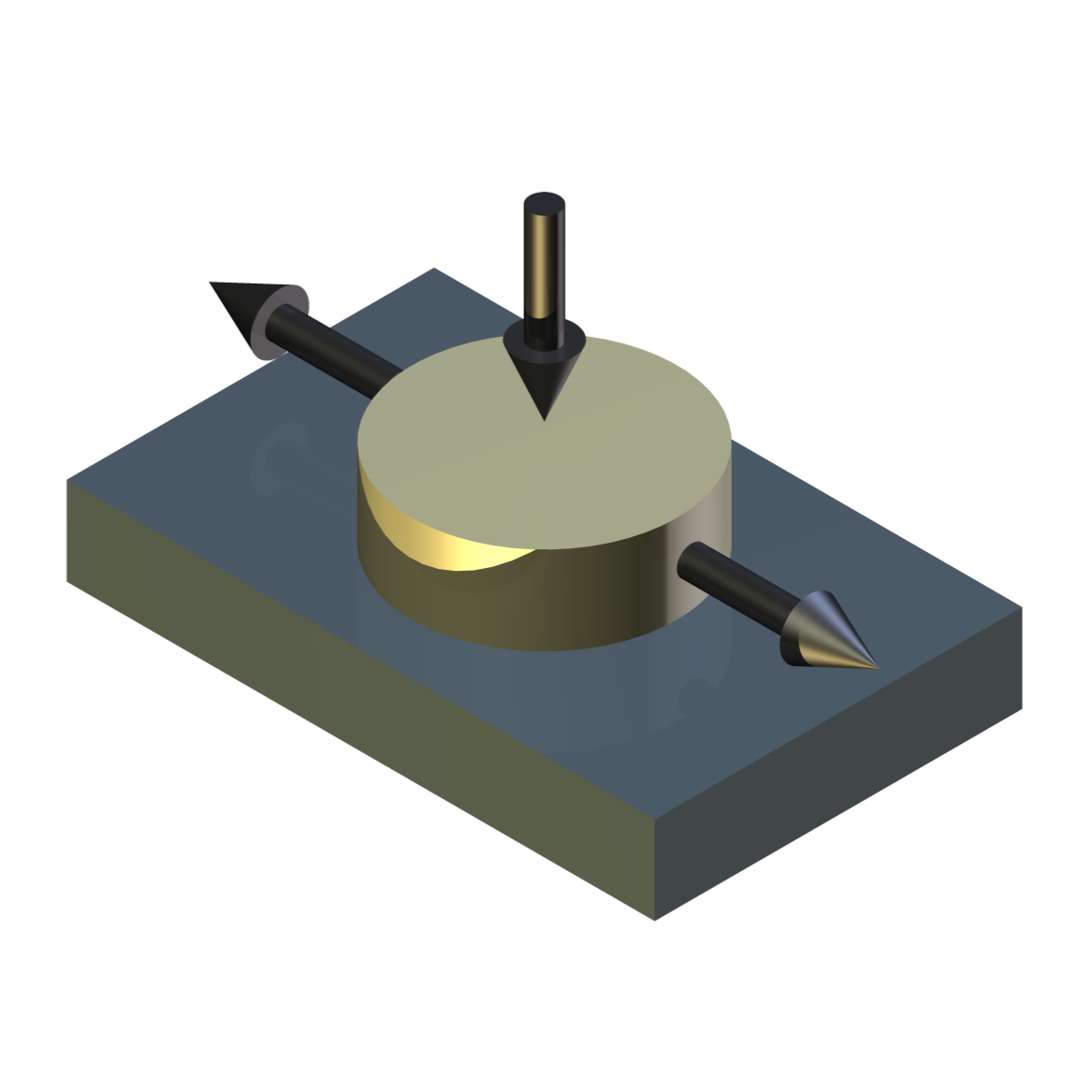

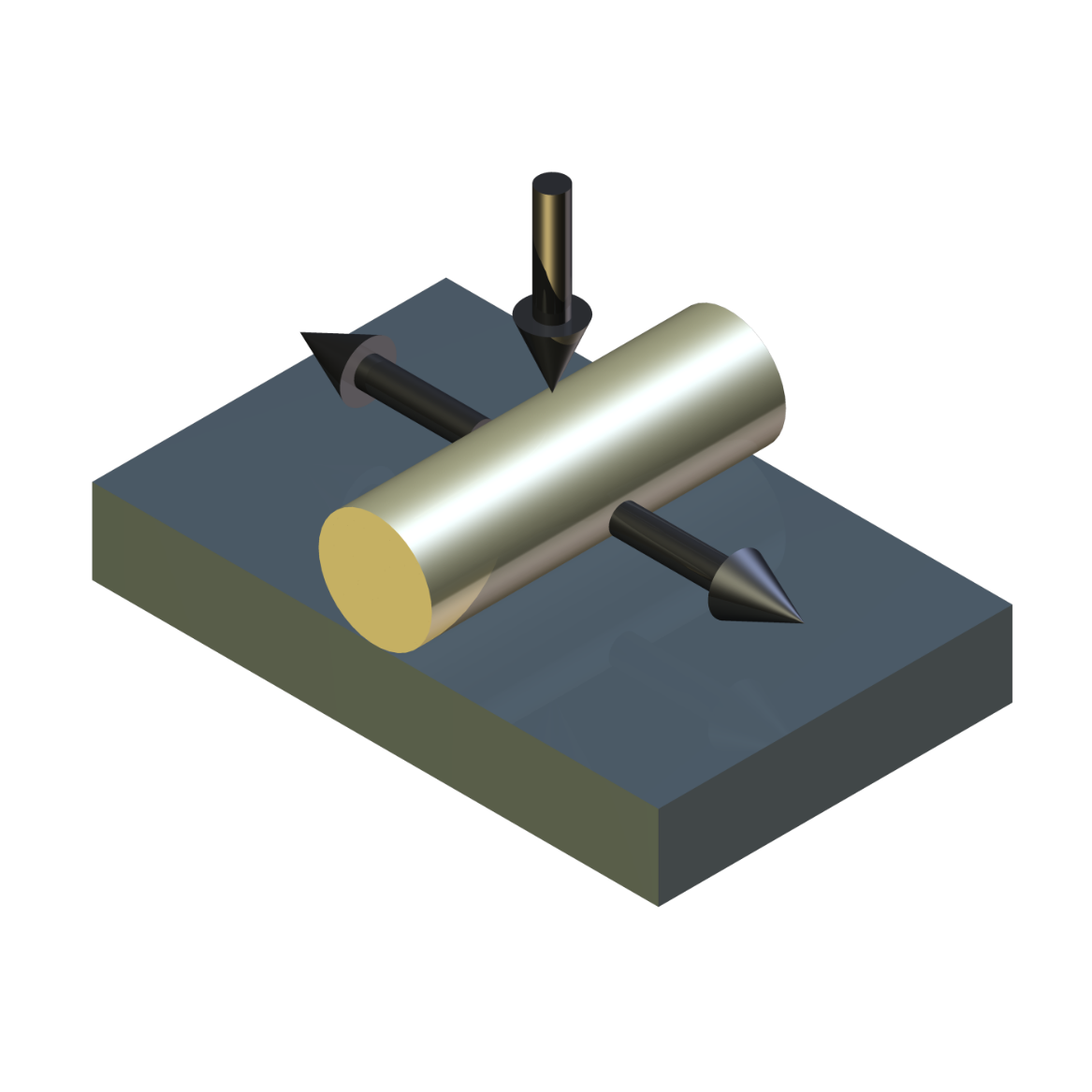

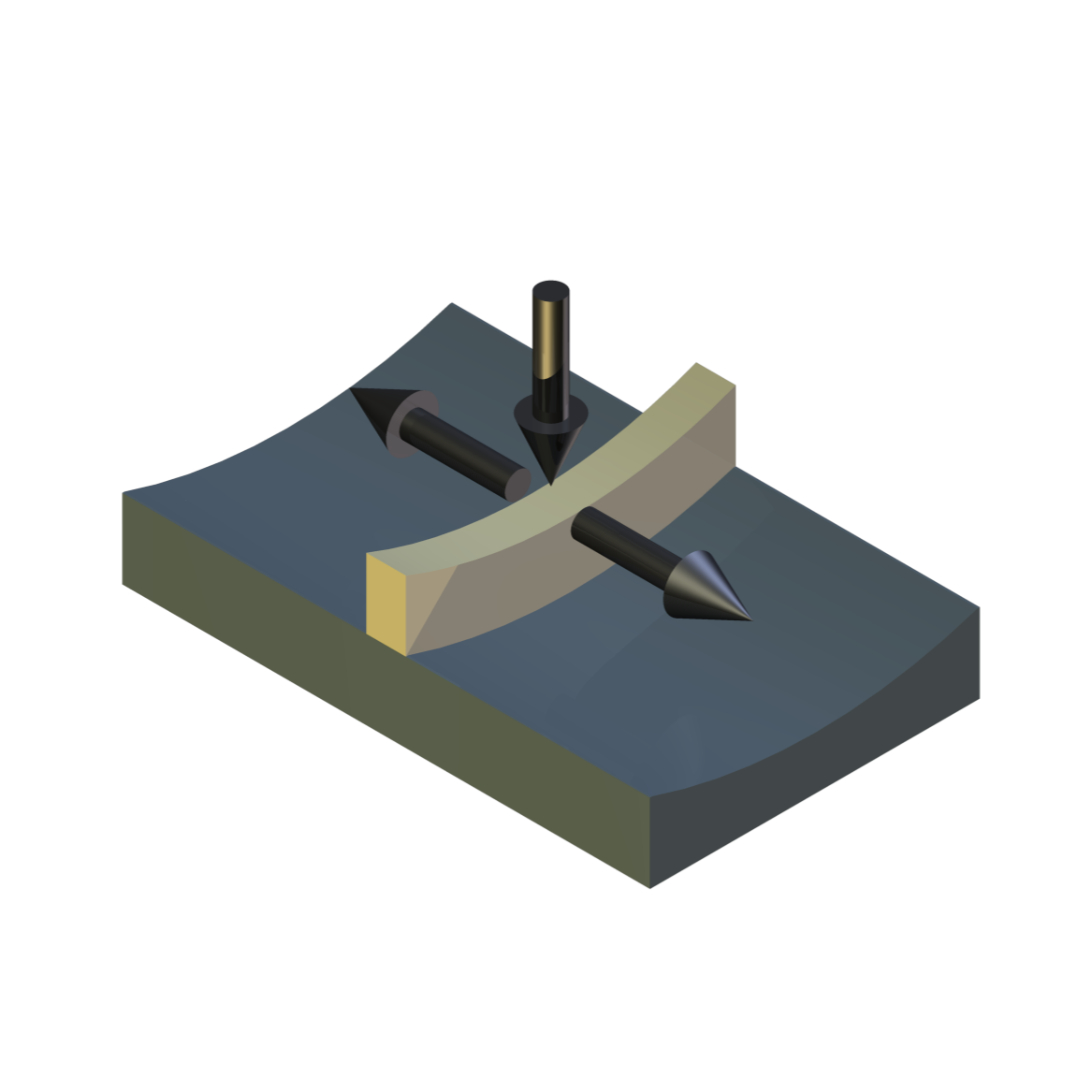

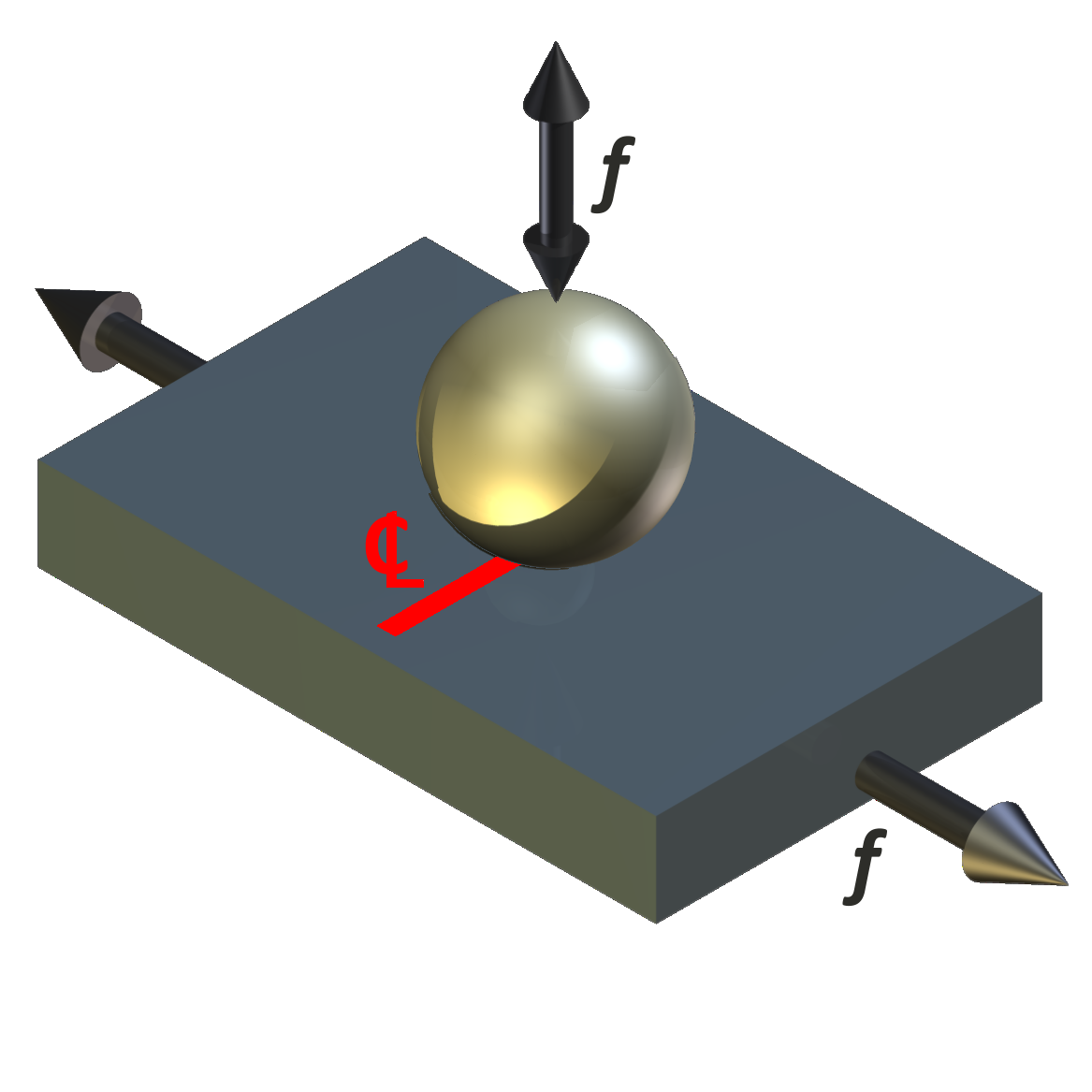

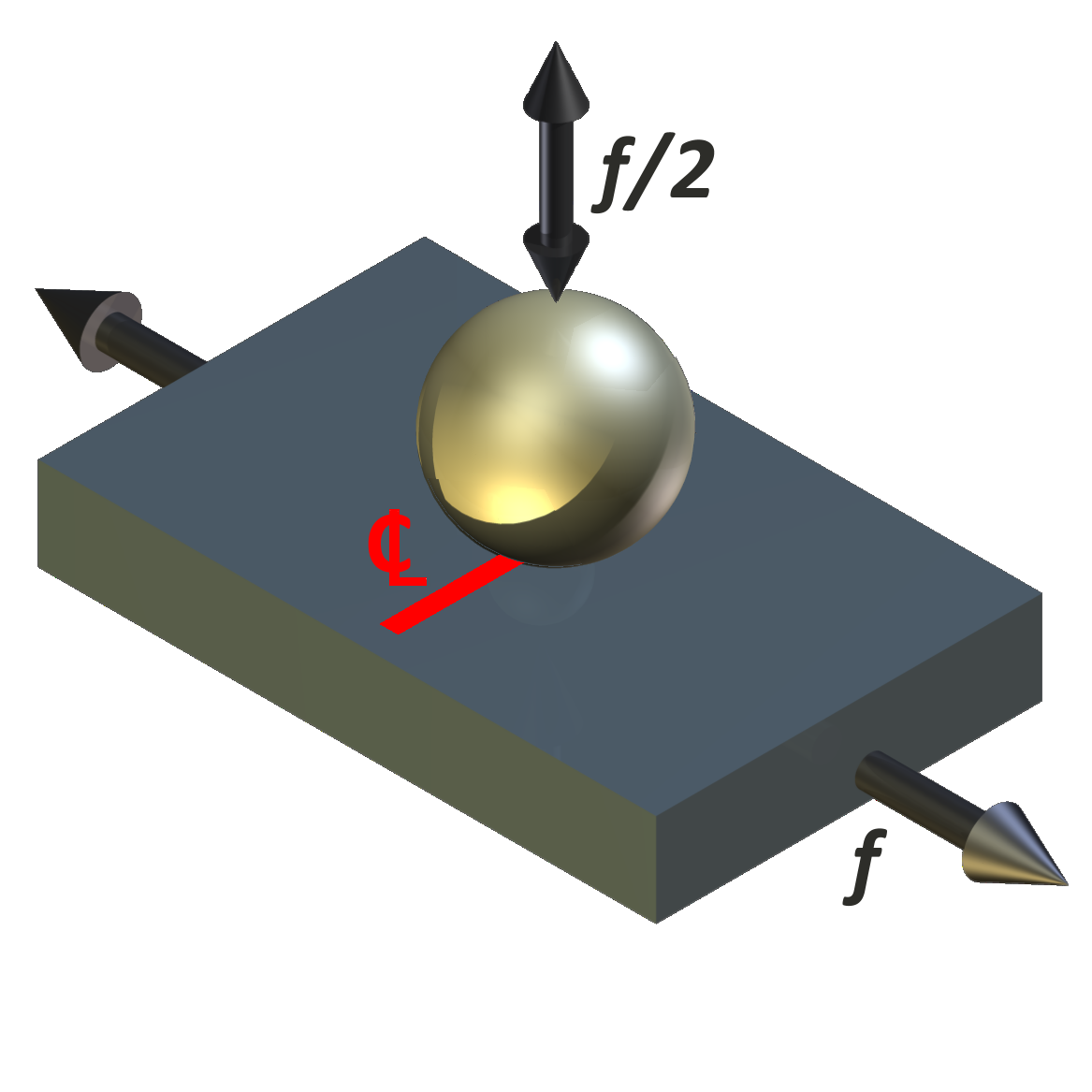

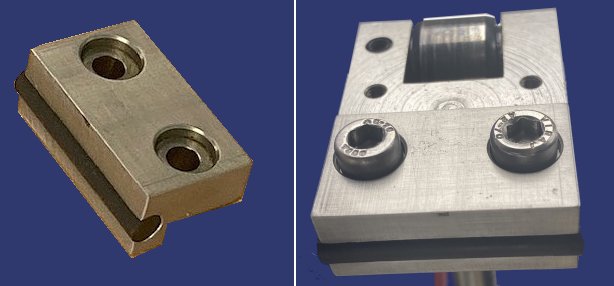

Moving Specimen

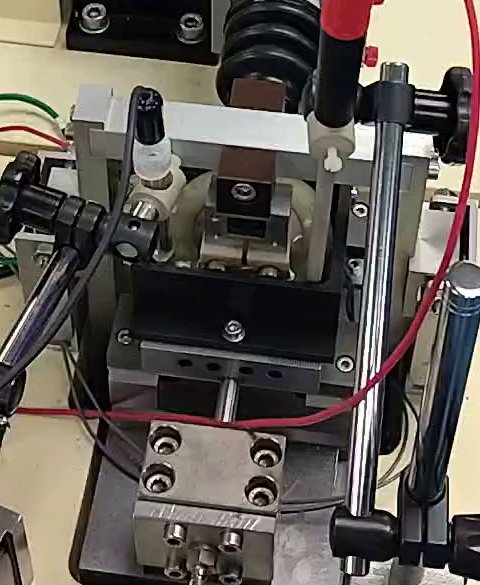

A number of different geometries can be accommodated by using simple clamping fixtures.

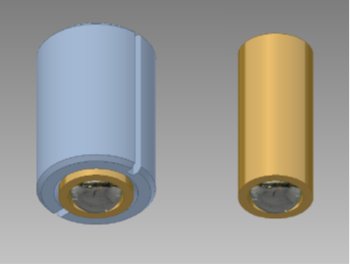

6 mm ball carrier in standard sleeve

10 mm ball carrier

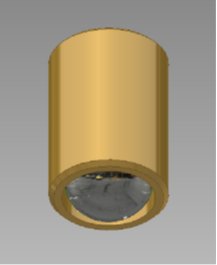

6 mm diameter line contact tooling

Self-aligning area contact tooling

Self-aligning area contact toolingThe mechanical drive comprises a motor driven scotch yoke assembly, providing pure sinusoidal motion. The stroke length is altered manually by adjusting eccentric cams on an eccentric shaft.

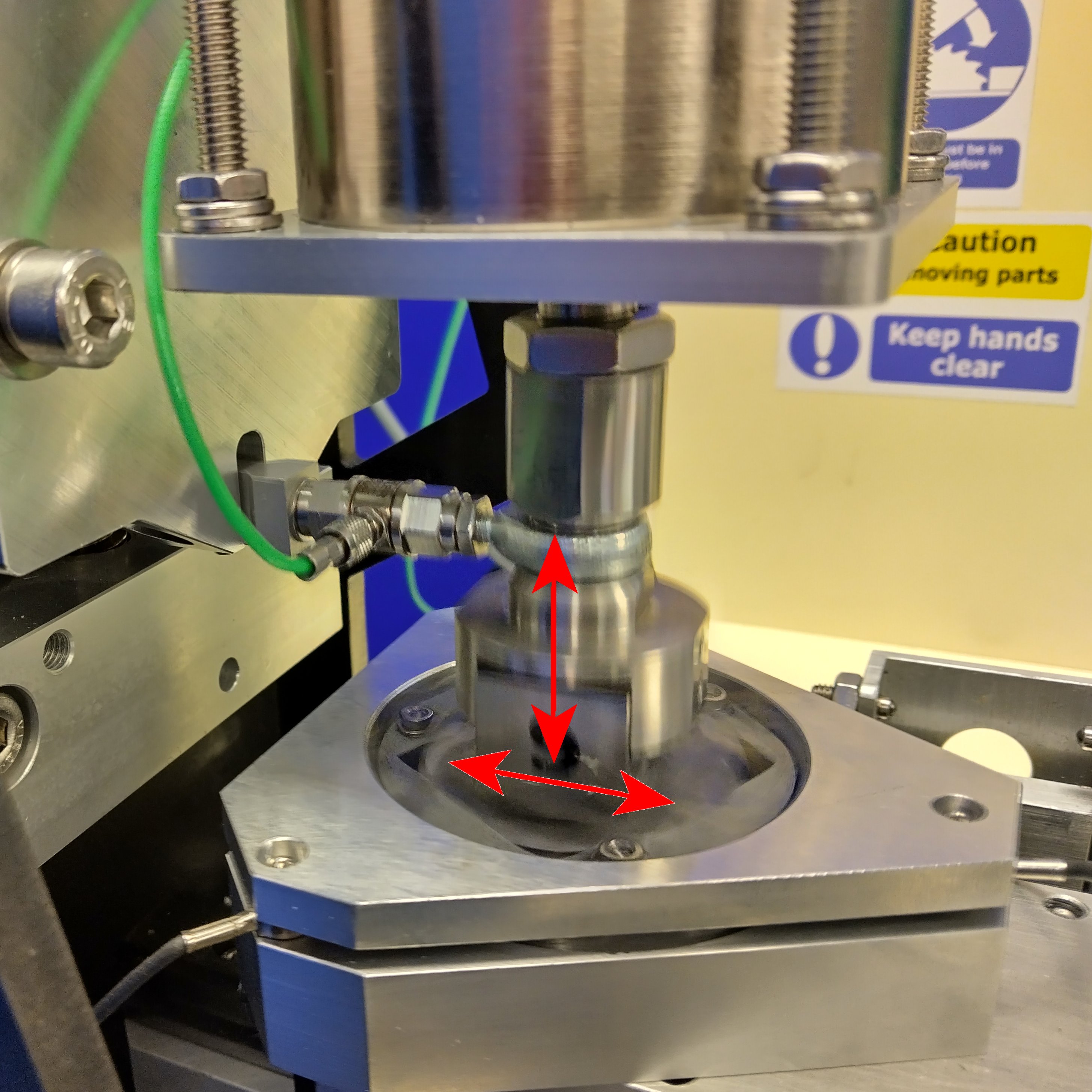

The load is applied to the moving specimen through a lever mechanism actuated by a servomotor and spring, acting through a needle roller cam follower. A force transducer on the lever measures the applied load.

Fixed Specimen

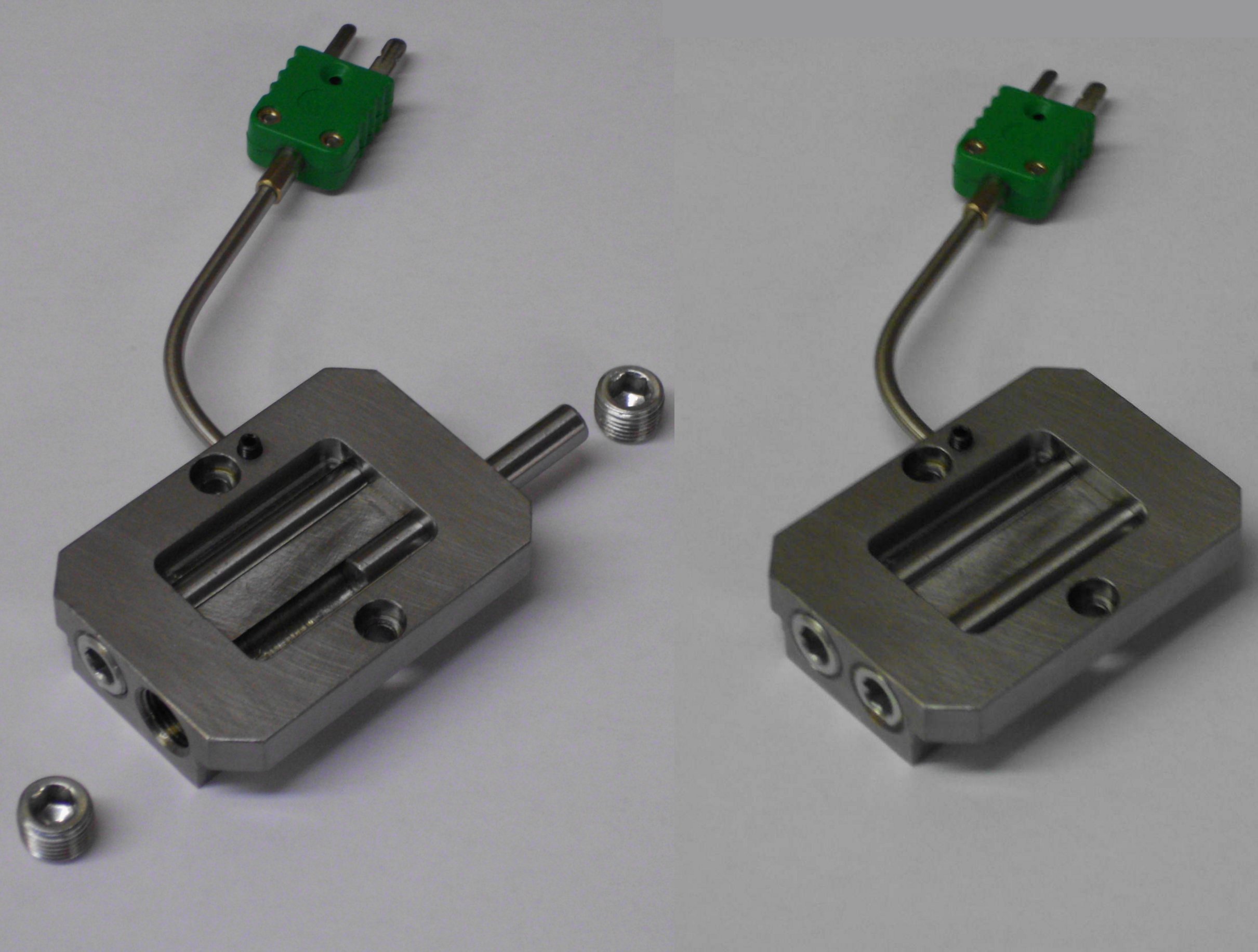

The fixed specimen is located in a bath clamped to a heater block. The heater block is mounted on flexures, with horizontal forces resisted by a piezo force transducer, sensing the friction force.

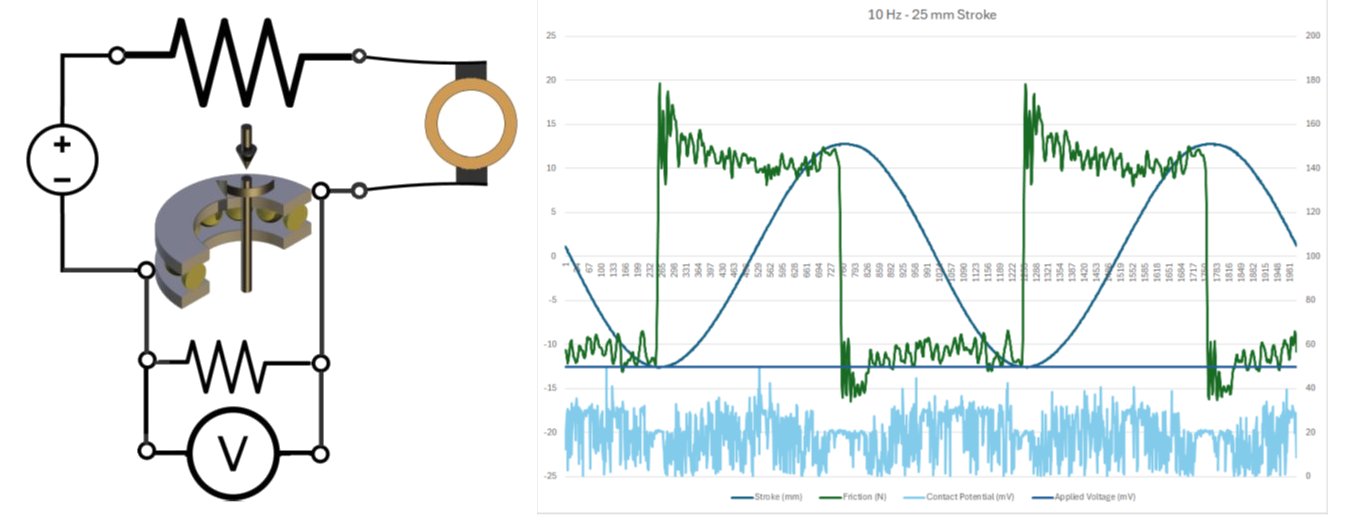

The moving specimen carrier is electrically isolated contact resistance measurement using a Lunn-Furey circuit. This is a high ratio potential divider with the tribo-contact acting as an electrical switch, in parallel with the low resistance side of the potential divider, with the resulting voltage being measured. The voltage across the tribo-contact is typically set to a maximum of between 20 and 50 mV.

Wear

Wear is not directly monitored on the basic machine, so assessments are made from post-test wear scar sizes.

The optional TE 77/WEAR provides continuous measurement of the wear displacement of the moving specimen relative to the fixed specimen. TE 77/PROFILE allows periodic in situ measurement of the fixed specimen wear.Low Speed Data

Analogue input channels are sampled and data logged at a maximum rate of ten samples per second. Time smoothing and averaging functions are provided by in hardware and software.

High Speed Data

The high-speed data acquisition interface provides programmable burst data acquisition of friction, contact potential and stroke position, using a 16-bit six channel multi-function ADC, with programmable data acquisition rates up to 50 kHz. Data is buffered and stored direct to hard disc with a separate file automatically created for each acquisition cycle.

Friction Noise

By rectifying the instantaneous friction force signal and subtracting the r.m.s. average, a resulting signal corresponding to the perturbations (friction noise) can be produced. This can be used as a measure of the orderliness or otherwise of the friction signal.

Comparisons and Advantages

Generation of Wear

The longer stroke capability of the TE 77 makes it a more effective wear generator than short stroke electro magnetically driven devices. It also allows tests to be performed using variable contact width, hence variable contact pressure, curved edge fixed specimens.

Entrainment and Wear Debris

The ability of the moving specimen to “expose” all parts of the fixed specimen depends on the contact length being not more than half the stroke length. This has implications for lubricant entrainment, for surface activation and for the discharge of wear debris from the contact.

Very Low Frequencies

Interchangeable gearboxes allow tests to be run at frequencies down to 0.01 Hz, for investigating low velocity sliding and investigating stick-slip.

Optional Accessories

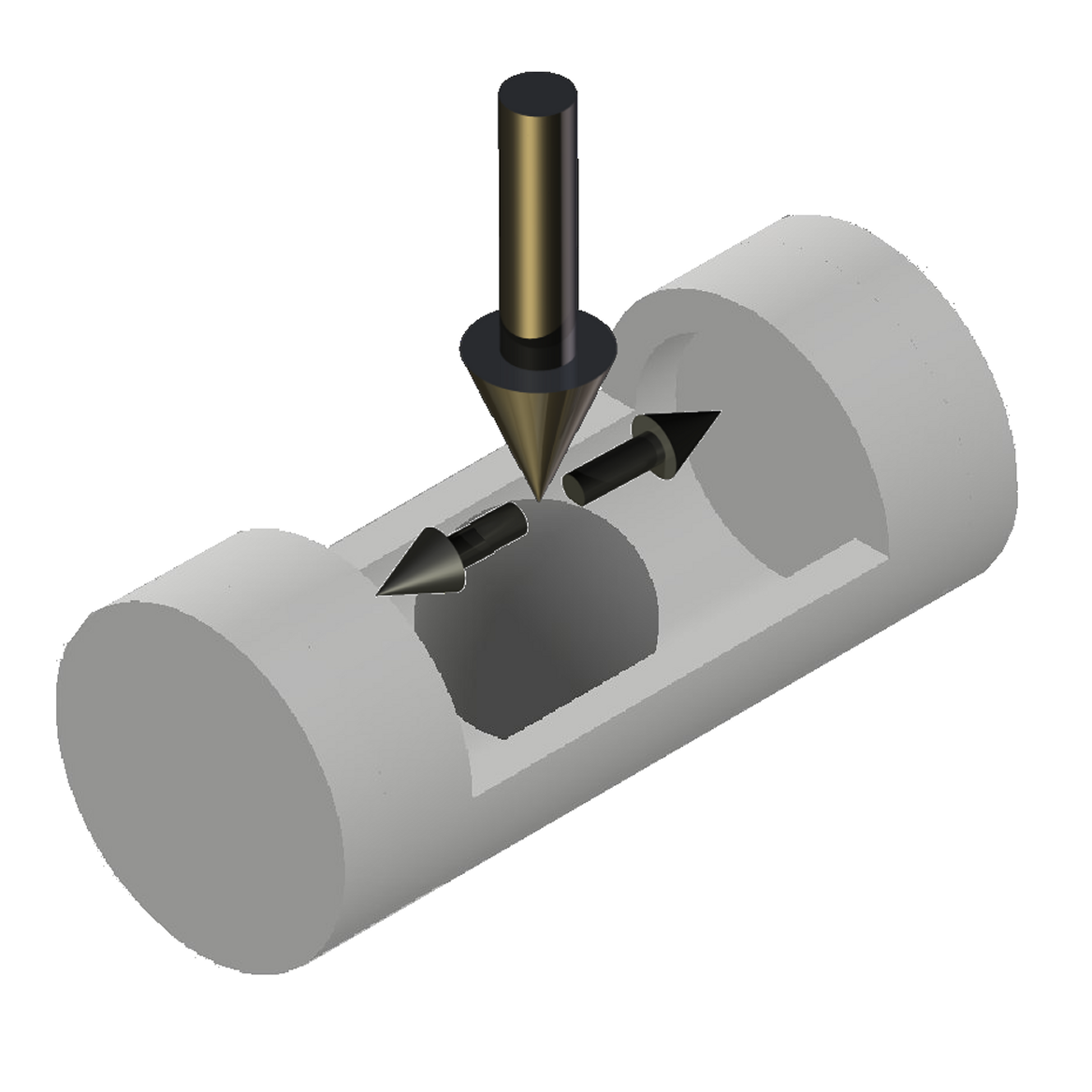

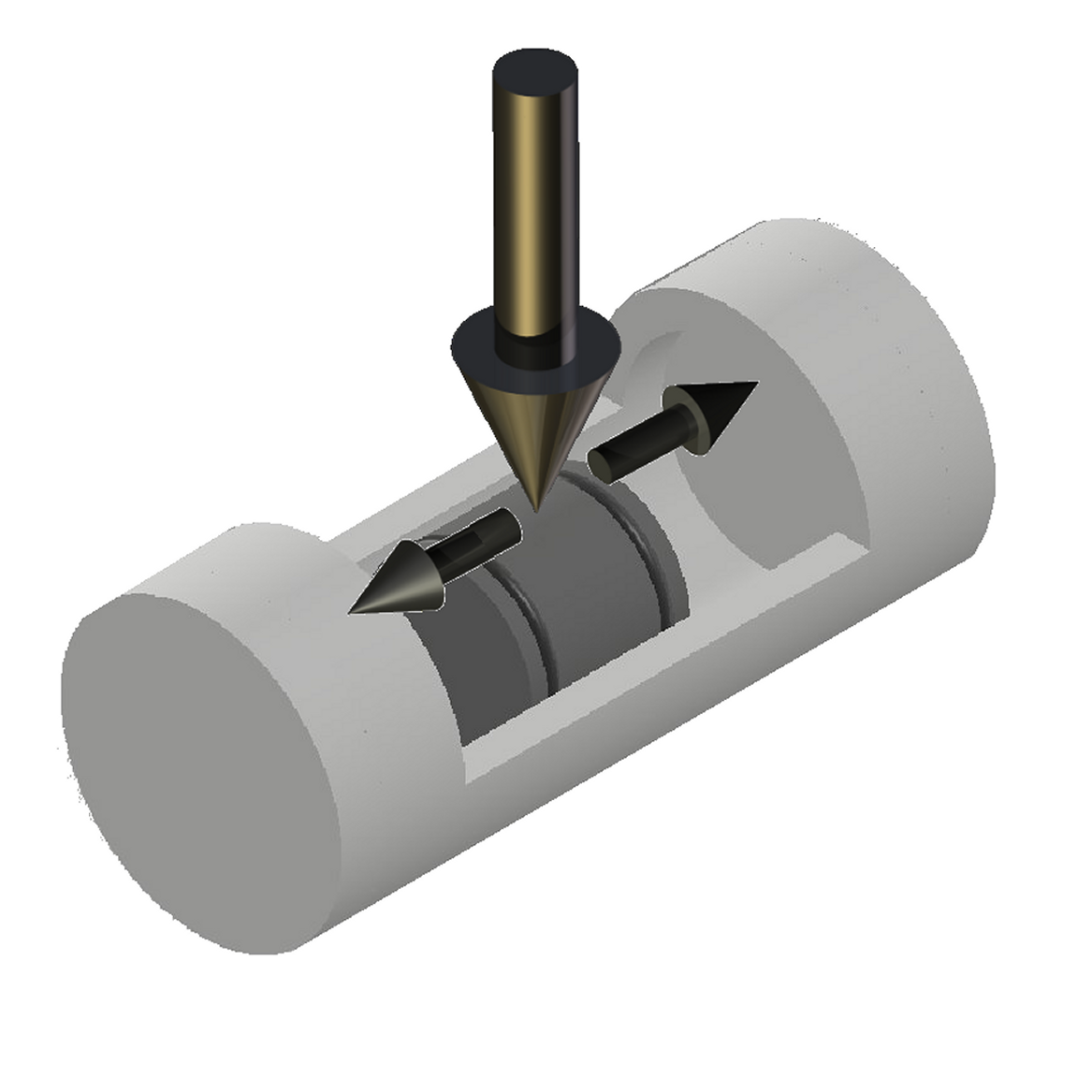

TE 77/SRC Adjustable Radius Piston Ring Clamp

The clamp allows the ring curvature to be adjusted to allow ring samples to conform to liner samples. The standard clamp can accommodate rings of diameter 90 to 110 mm. A larger clamp has been designed to accommodate rings up to 200 mm diameter.

TE 77/TRC Adjustable Radius Twin Piston Ring Clamp

This arrangement allows two adjustable radius ring clamps to be mounted in series so that tests can be run with two ring samples on a common liner section sample.

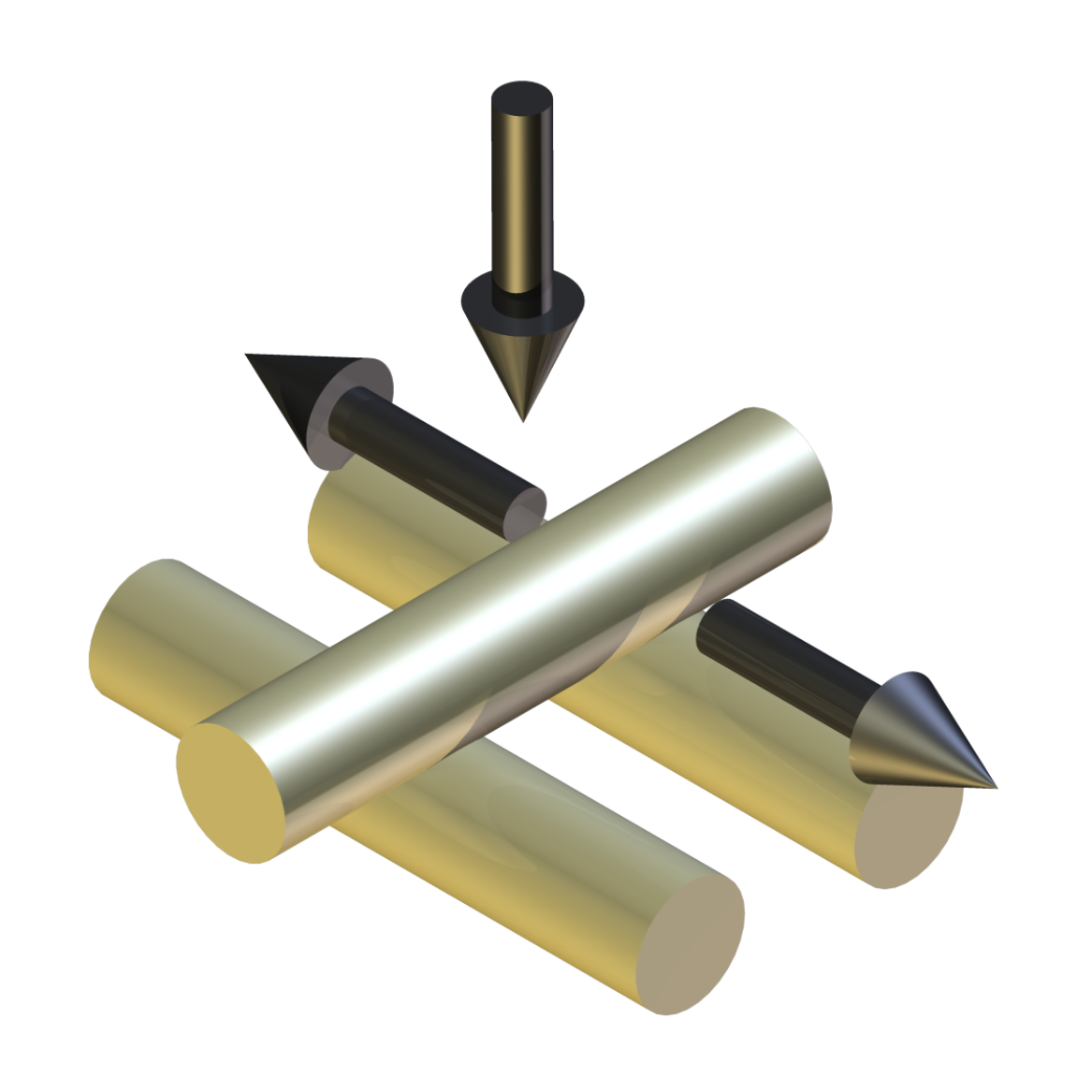

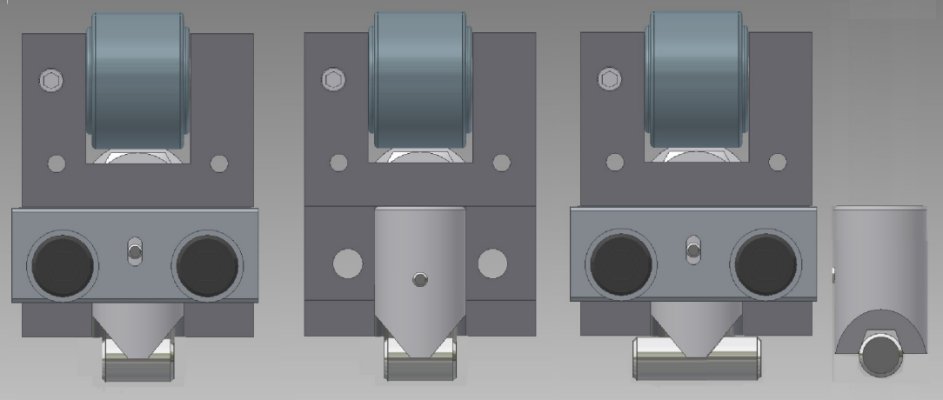

TE 77/PT Pin on Twin Test Bath

The pin on twin test bath allows tests to be performed with a self-locating crossed cylinder geometry. This is a technique originally developed by Dr Peter Blau at Oakridge National Laboratories.

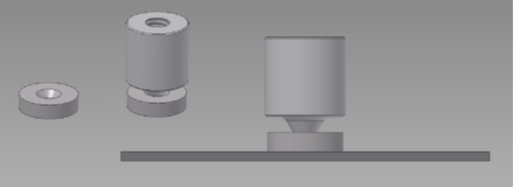

TE 77/WEAR On-Line Wear Monitoring System

TE 77/WEAR is a non-contact measuring system. A capacitance probe is mounted in the moving specimen carrier, above a reference surface mounted on the edge of the specimen bath. The variations in the gap due to wear, lubricant film formation, thermal expansion or a combination of these are picked up by the system. The measuring resolution is greatest when the temperature of the fixed specimen is held constant.

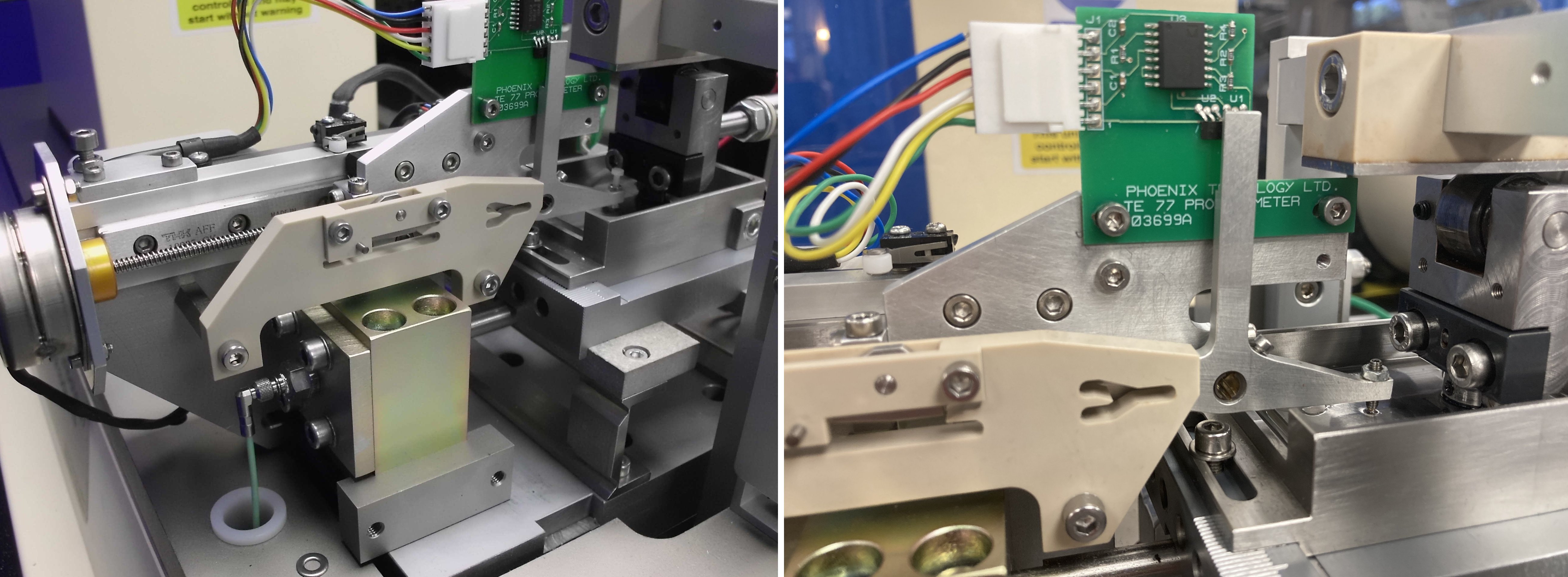

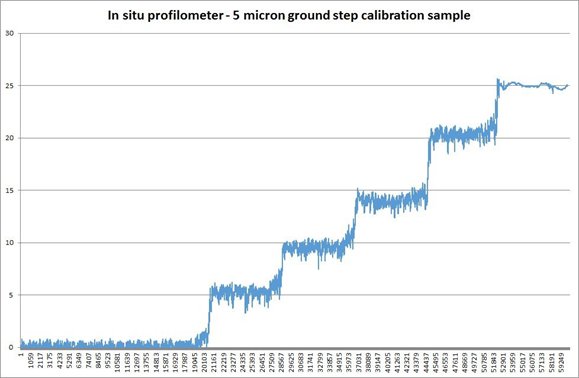

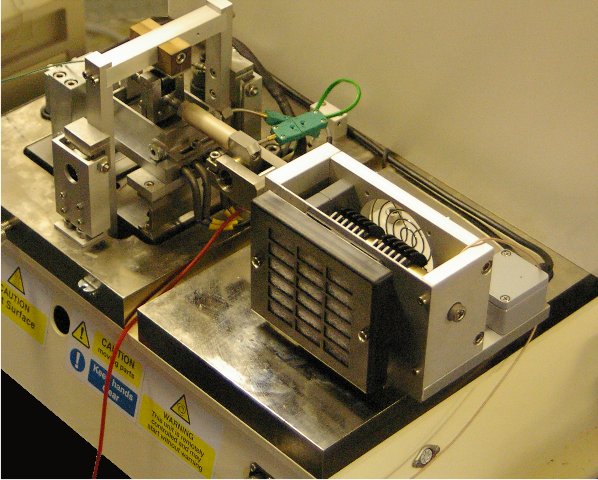

TE 77/PROFILE In situ Profilometer

This is a tactile profilometer, which is used to make periodic measurements of just over half the fixed specimen wear scar. During a measurement cycle, reciprocating motion is stopped and the moving specimen moved to the opposite stroke end to the profilometer, which is then triggered to probe the fixed specimen surface, from just over the mid-stroke position to the stroke end nearest the profilometer.

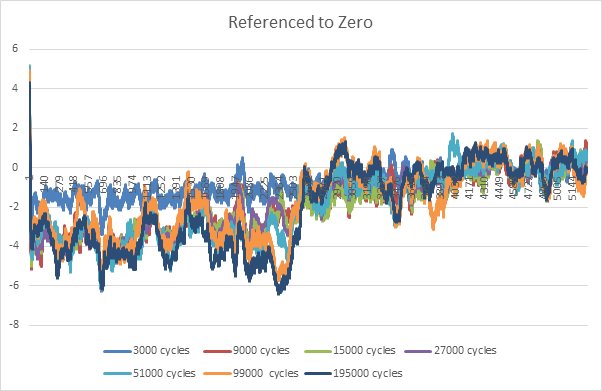

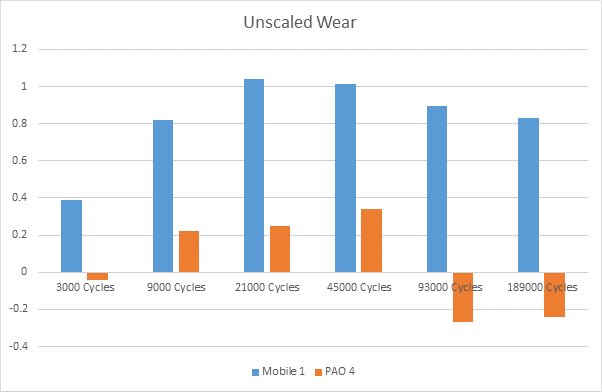

At the start of a test, an initial surface profile is measured. Subsequent measurements are referenced to this value and recorded as: Current Measured Value – Initial Reference Value.

The measurements will show both wear of the fixed specimen and material transfer from the moving to fixed specimen.

TE 77/GB/20 Gearbox for 20:1

This gearbox mounts between the drive motor and camshaft, providing a 20:1 reduction in operating frequency.

TE 77/GB/100 Gearbox for 100:1 Reduction

This gearbox mounts between the drive motor and camshaft, providing a 100:1 reduction in operating frequency.

TE 77/INERT Gas Enclosure

The TE 77/INERT Gas Enclosure is a chamber that fits in place of the standard specimen bath and encloses the fixed and moving specimens. The reciprocating specimen carrier is sealed by a rubber bellows fitted between the reciprocating drive assembly and the chamber. Load is applied through a flexible membrane in the top of the chamber. Inert gases, water vapour and mildly corrosive gases may be used.

TE 77/COOLER

This replaces the standard fixed specimen heater block assembly with a cooler pad. A refrigeration unit delivers pressurised refrigerant direct to an expansion probe, embedded in the cooler pad, removing the requirement for an intermediate heat transfer fluid. This arrangement allows temperatures from ambient to -50°C to be achieved. To avoid ice formation, a test enclosure is included, fed with cool and dry air, delivered via a vortex cooler and a desiccant tube. A compressed air supply is required.

TE 77/ECP Electro-chemical Cell & Potentiostat

The electro-chemical test bath is supplied Silver/Silver Chloride Reference Electrode, Platinum Mesh Counter Electrode and Gamry Instruments Reference 600 Potentiostat/Galvanostat/ZRA. It includes the following Global Software Licenses: DC105 DC Corrosion, CPT110 Critical Pitting Temperature, EN120 Electrochemical Noise Experiment, EFM140 Electrochemical Frequency Modulation, PHE200 Physical Electrochemistry, PV220 Pulse Voltammetry, EIS300 Electrochemical Impedance, ESA410 Electrochemical Signal Analyzer and VFP600 Virtual Front Panel & PWR800 Electrochemical Energy. The assembly includes a modified moving specimen head and a Faraday cage.

TE 77/PUMP Peristaltic Pump and Drip Feed System

The TE 77/PUMP drip feed system uses a variable speed peristaltic pump. The package includes the pump controller and pump head, three sizes of pump tubing and universal pipe fittings.

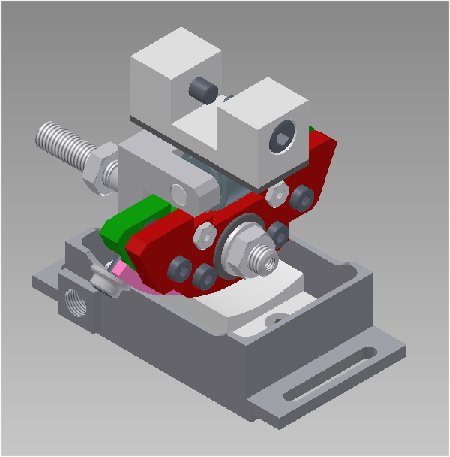

TE 77/PIEZO Fretting Test Adapter

This adapter replaces the standard reciprocating drive assembly with a piezo actuator drive system. This is for performing fretting tests at strokes from 10 to 100 microns with frequencies up to 100 Hz with control of mid-stroke position and amplitude to +/-0.2 microns.

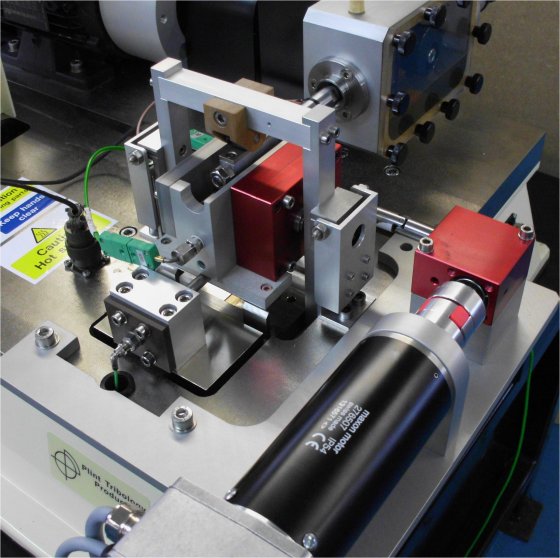

TE 77 Slide/Roll Adapters

Many wear and failure mechanisms in gears and valve trains can be modelled with sliding-rolling contacts, in which the point of contact moves on both surfaces. The development of the “Energy Pulse” (EP) criterion led to the development of two slide-roll adapters for the TE 77.

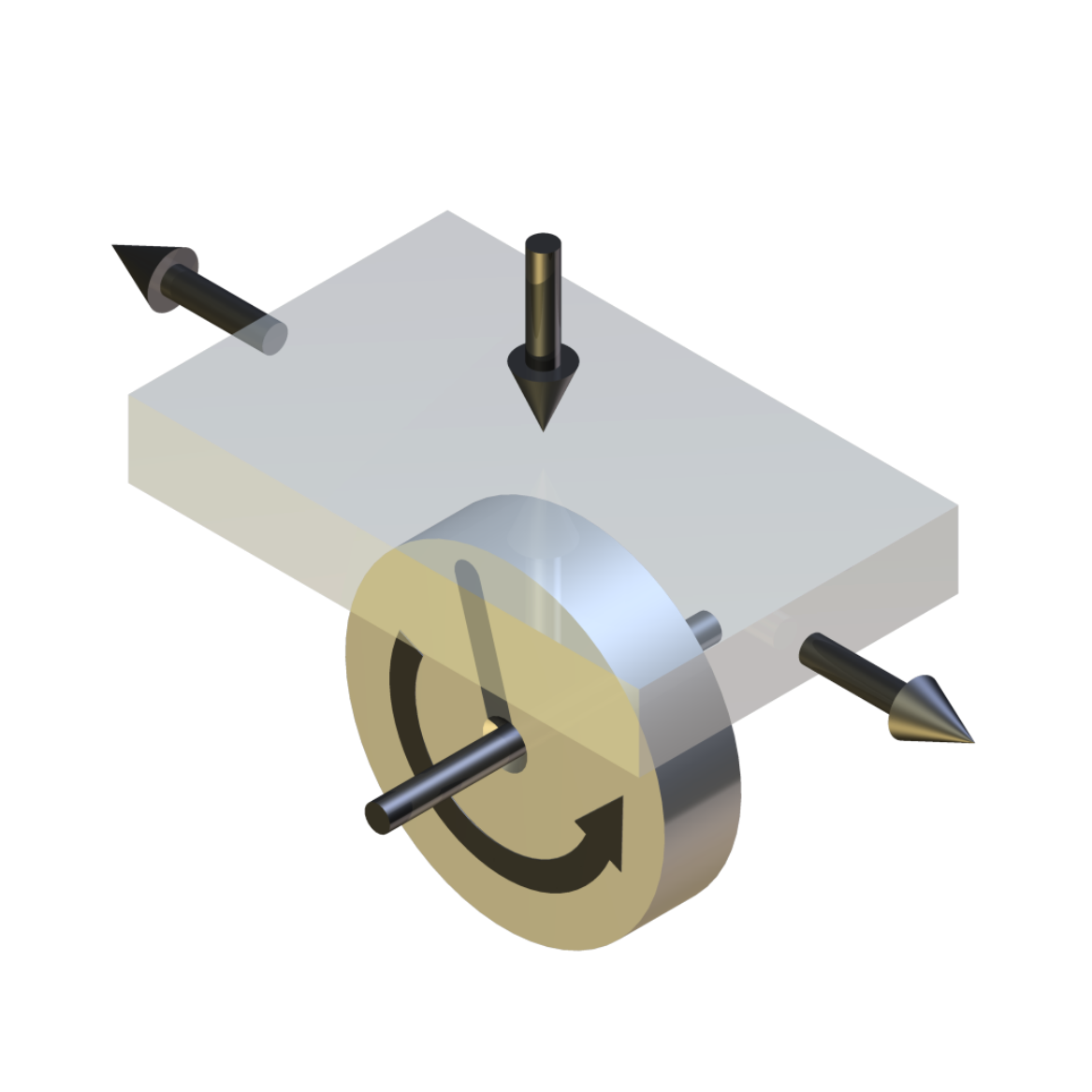

TE 77 EP-CAM

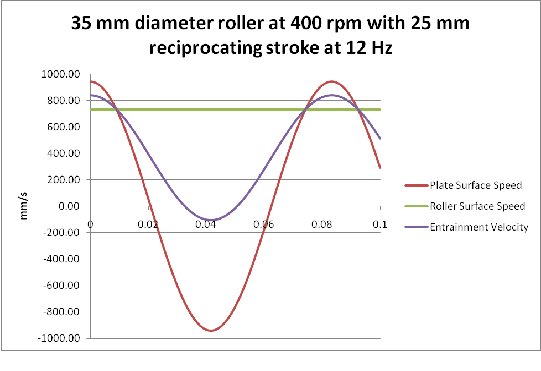

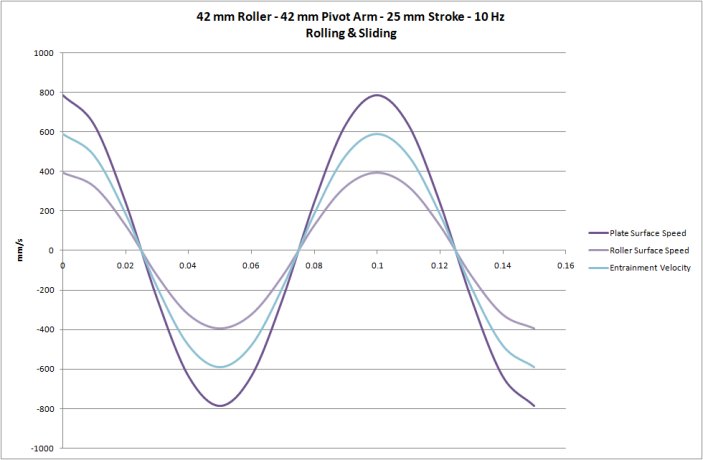

In this arrangement, a plate specimen is reciprocated against a rotating roller in what has been termed a “Reciprocating Amsler” test configuration. This produces asymmetrical lubricant entrainment: positive with the surface of the plate and roller moving in the same direction and, depending on relative speeds, negative when moving in opposite directions, hence a model for the kind of entrainment conditions occurring in a cam-follower contact. No point on either specimen remains in continuous contact.

The rotational speed of the roller can be adjusted independently of the reciprocating rate of the plate, allowing a range of different varying entrainment velocities to be set. In addition to adjusting the varying slide/roll ratio by adjusting the rotational speed and reciprocating frequency, the stoke length can of course be adjusted.

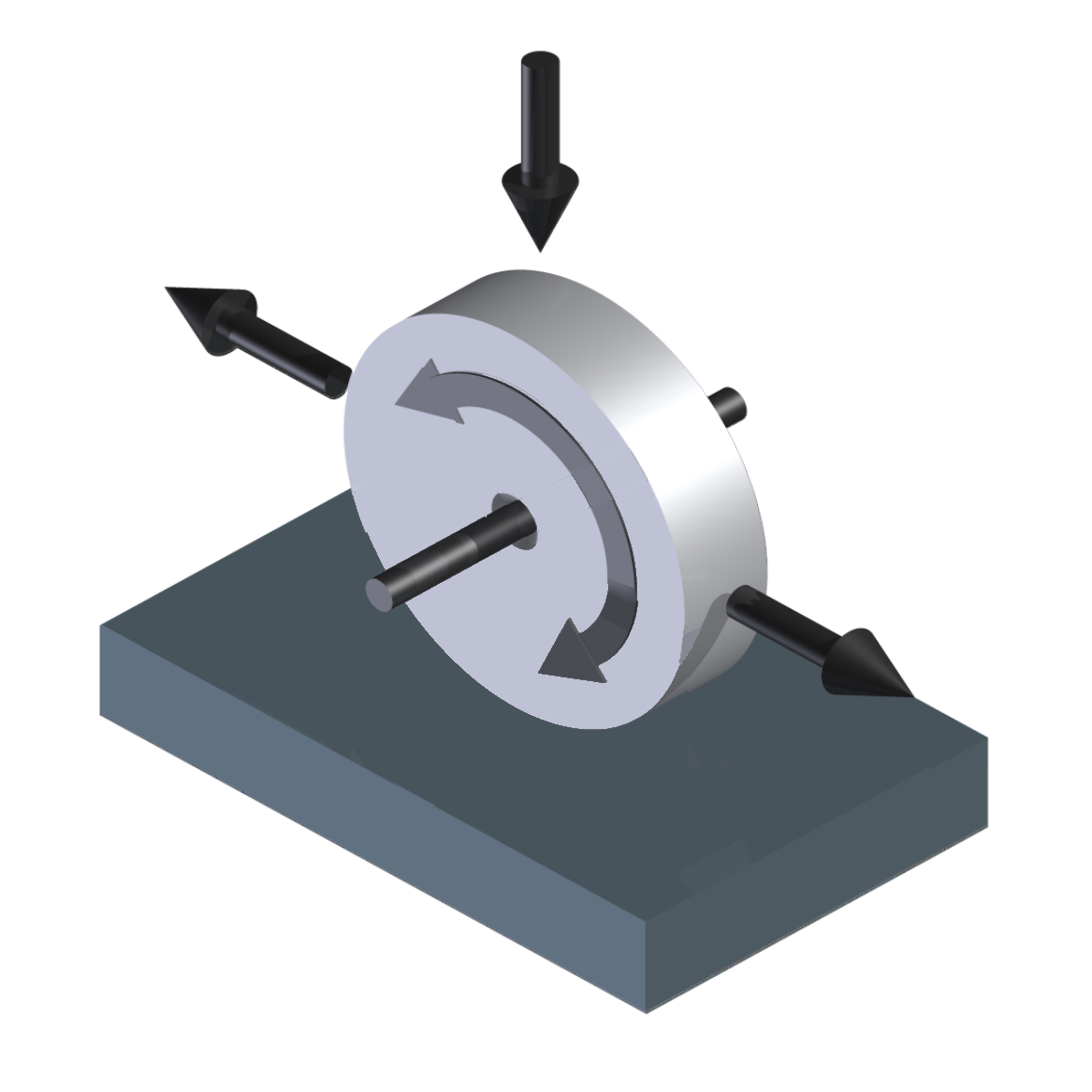

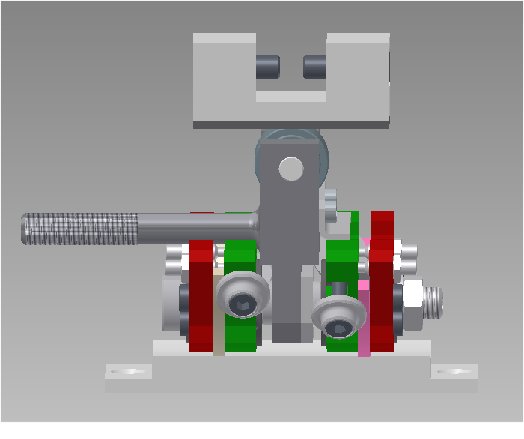

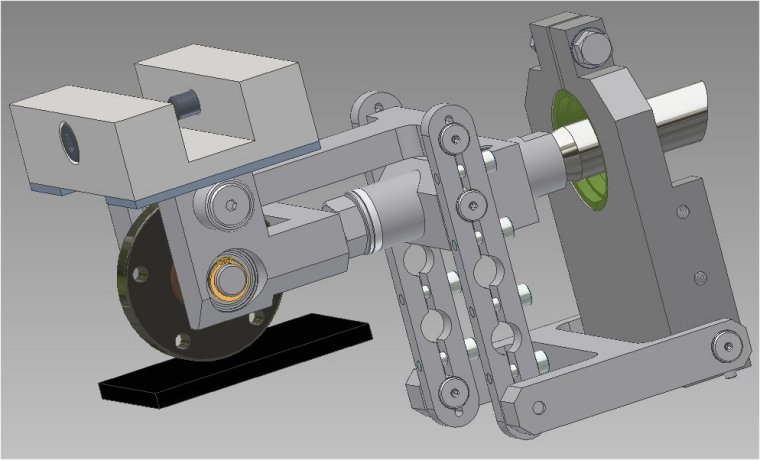

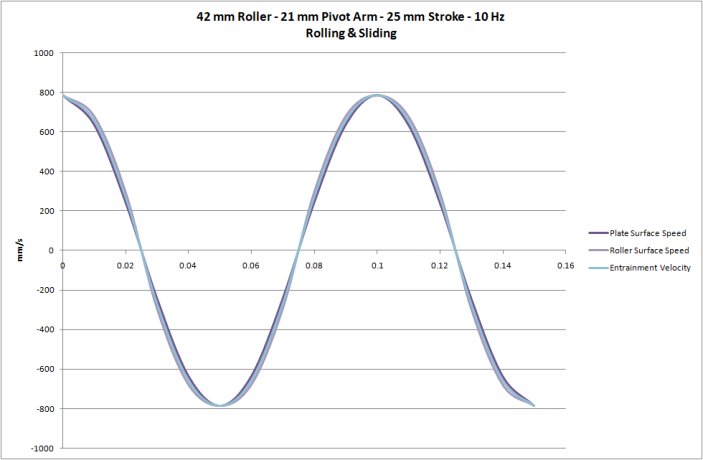

TE 77 EP-GEAR

In this arrangement, a roller is reciprocated against a plate specimen and a rocking motion induced by a linkage mechanism. The entrainment velocity varies with stroke, symmetrically about the mid-stroke position. The result is that the point of contact moves on both specimens, similar to gear teeth sliding and rolling about the pitch point. No point on either specimen remains in continuous contact.

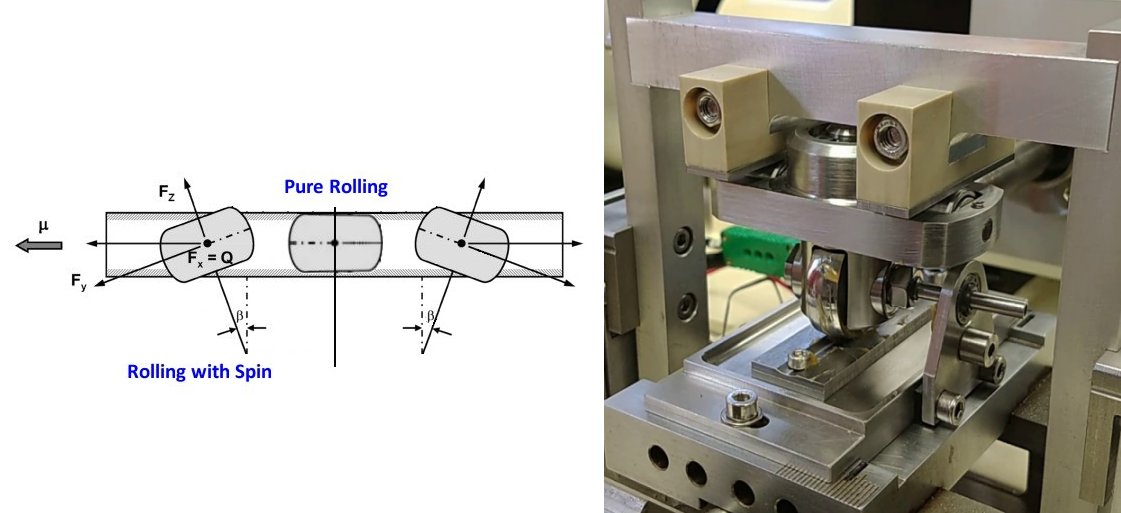

TE 77/CSA Contact Spin Adapter

This adapter models sliding-rolling contacts with contact spin. This can be used for modelling, at longer strokes, the motion in a tripod CV joint, and at shorter strokes, amplitude rotational displacement in rolling element bearings.TE 77/IFA Impact Fretting Adapter

The impact fretting adapter is mounted in place of the standard fixed specimen assembly and comprises a voice coil actuator mounted vertically on a motorised linear slide. A reciprocating plate specimen assembly is driven by the standard scotch yoke mechanism, with the vertical motion of the voice coil actuator synchronised with the horizontal motion.

The voice coil actuator is suspended from a flexural bearing with the armature extension rod restrained in the horizontal plane by a piezo transducer, acting in line with the horizontal reciprocating motion. The plate specimen is mounted on piezo transducer which detect normal force. -

Technical Specifications

Contact Configurations: Ball on Plate (Point Contact) Cylinder on Plate (Line Contact) Area Contact Optional Configurations: Piston-Ring and Cylinder Liner ISO Fuel Test Specimens Load Range: 5 to 1000 N Loading Rate: 50 N/s Temperature Range: Ambient to 600°C Heating Power: 800 W Temperature Sensor: k-type thermocouple Frequency Range: 2 to 50 Hz Stroke Range: See following tables Contact Potential: 50 mV dc signal Friction Transducer: Piezo-Electric Type Force Range: – 500 to 500 N Stroke Transducer: Magneto Inductive Maximum Stroke: 25 mm Linearity: 0.50% Low Speed Interface: Serial Link Interface Module Resolution: 12 bit Number of Input Channels: 1 to 8 Number of Output Channels: 1 to 4 Maximum Data Rate: 10 Hz High Speed Interface: USB Resolution: 16 bit Number of Input Channels: 6 Maximum Data Rate: Six channels at 50 kHz Software: COMPEND 2000 Motor: 1.1 kW a.c. vector motor with 2048 ppr encoder Plate Specimen: 38 mm x 58 mm x 4 mm thick (typical) Point Contact: 6 mm, 3/8 inch and 10 mm diameter ball Line Contact: 6 mm diameter x 16 mm long pin Area Contact: 12 mm diameter x 4 mm thick disc Stroke Range: Continuously Variable Cam – 0 to 12.5 mm Angle – degrees: Minimum – mm Maximum – mm 0 0 2 18 1.04 3.04 36 2.65 4.65 54 4.25 6.25 72 5.75 7.75 90 7.09 9.09 108 8.24 10.24 126 9.17 11.17 144 9.85 11.85 162 10.26 12.26 180 10.4 12.4 Step Variable 0 to 12.5 mm: Angle – degrees: Nominal Stroke – mm 0 0 18 1.94 36 3.83 54 5.63 72 7.29 90 8.77 108 10.03 126 11.05 144 11.79 162 12.25 180 12.5 Step Variable 12.5 to 25 mm: Angle – degrees: Nominal Stroke – mm 0 12.5 18 13.05 36 14.26 54 15.97 72 17.89 90 19.8 108 21.54 126 23 144 24.09 162 24.77 180 25 Controlled Parameters Frequency Load Temperature Test Duration Measured Parameters Load Low speed data Friction (rms) Low speed data Friction (instantaneous) High speed data Friction Noise (time smoothed) Low speed data Contact Potential (time smoothed) Low speed data Contact Potential (instantaneous) High speed data Stroke Position (instantaneous) High speed data Temperature Low speed data Frequency Low speed data Number of Cycles Low speed data Wear (with TE 77/WEAR) Low speed data Derived Parameters Friction Coefficient Low speed data Real-time Graphs All low speed data (user selectable) Burst high speed data (user selectable) ACCESSORIES & ADAPTERS TE 77/WEAR On-Line Wear Monitoring System Contact Configurations: Ball on Plate Cylinder on Plate Area Contact Piston Ring on Liner Displacement Range: 0 to 1 mm Resolution: 0.2µm Accuracy: within 3 % Allowed Temperature: – 20°C to 200°C Output Range: 1 mV = 1µm TE 77/GEAR/20 Gearbox for 20:1 Reduction Frequency Range: 0.1 Hz to 2.5 Hz TE 77/GEAR/100 Gearbox for 1001 Reduction Frequency Range: 0.02 Hz to 0.5 Hz TE 77/INERT Gas Enclosure Maximum Pressure: 120 mm water Maximum Temperature: 200°C TE 77/COOLER Cooler Pad Minimum Temperature: -50°C TE 77/PUMP Peristaltic Pump and Drip Feed Maximum Pump Speed: 55 rpm Turn-Down Ratio: 110:01:00 Flow Rates: 0.02 to 2.3 ml/min with 0.5 mm bore tube 0.06 to 6.7 ml/min with 0.8 mm bore tube 0.22 to 24 ml/min with 1.6 mm bore tube Tube Wall Thickness: 1 mm TE 77/PIEZO Fretting Test Adapter Type of Contact: Ball/Flat Flat/Flat Line/Flat Type of Movement: Sine, Square and Triangular Load: 5 to 1000 N Friction Force: +/-500 N Maximum Stroke – continuously variable: 10 microns to 100 microns Resolution: +/-0.2 microns Frequency – continuously variable: 1 Hz to 100 Hz Maximum stroke at 100 Hz: 30 microns Maximum stroke at 50 Hz: 60 microns Maximum stroke at 20 Hz: 100 microns TE 77/EP-CAM Slide/Roll Adapter Contact Configuration: Plate on Cylinder (Line Contact) Roller Specimen Diameter: 35 mm Roller Width: 10 mm Plate Specimen: 50 mm x 12 mm x 3 mm Load Range: 1000 N Stroke Range: 25 mm Maximum Frequency: 20 Hz Maximum Rotational Speed: 1000 rpm Servo Motor Power: 400 W Temperature Range: ambient to 100°C Heating Power: 200 W Temperature Sensor: k-type thermocouple TE 77/EP-GEAR Slide/Roll Adapter Contact Configuration: Plate on Cylinder (Line Contact) Roller Specimen Diameter: 42 mm Roller Width: 5 mm Load Range: 1000 N Stroke Range: 25 mm Maximum Frequency: 10 Hz Services Electricity: 220/240 V, single phase, 50/60 Hz, 3.2 kW Installation Floor-standing machine: 900 mm x 900 mm x 600 mm high, 250 kg Packing Specifications: 1.33 m3, GW 410 kg, NW 310 kg -

Overview Videos

Machine Overview

Profilometer Overview

Stick Slip Tooling

Training Videos

Machine Training Video

Profilometer Training Video

Electro Chemical Cell Training Video

Impact Fretting Adaptor Video

-

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com