-

Description

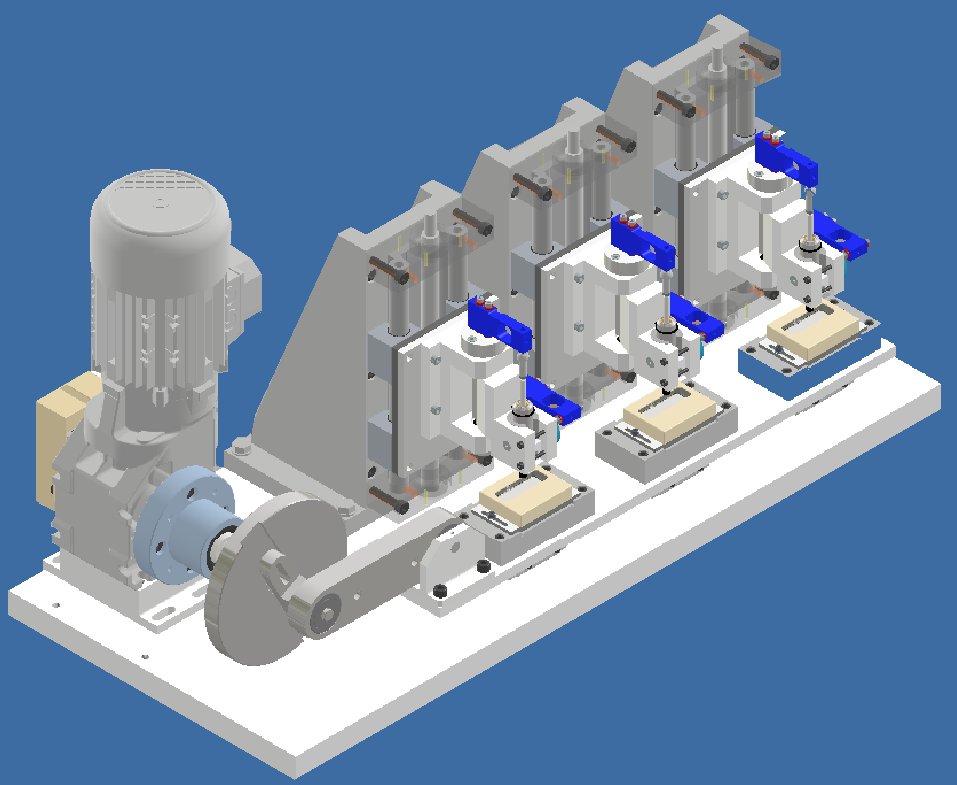

The TE 88 Reciprocating Pin on Plate machine is a three station wear and friction tester primarily designed for testing polymers and coatings in a production environment. The machine can also perform tests in accordance with ASTM F732.

The machine includes an a.c. variable speed gear-motor with variable throw crank, reciprocating assembly, three load, friction and wear pin carrier assemblies and a control and data acquisition system. Load is applied manually and measured with a force transducer. Friction is measured with a force transducer and wear is sensed by linear potentiometer.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

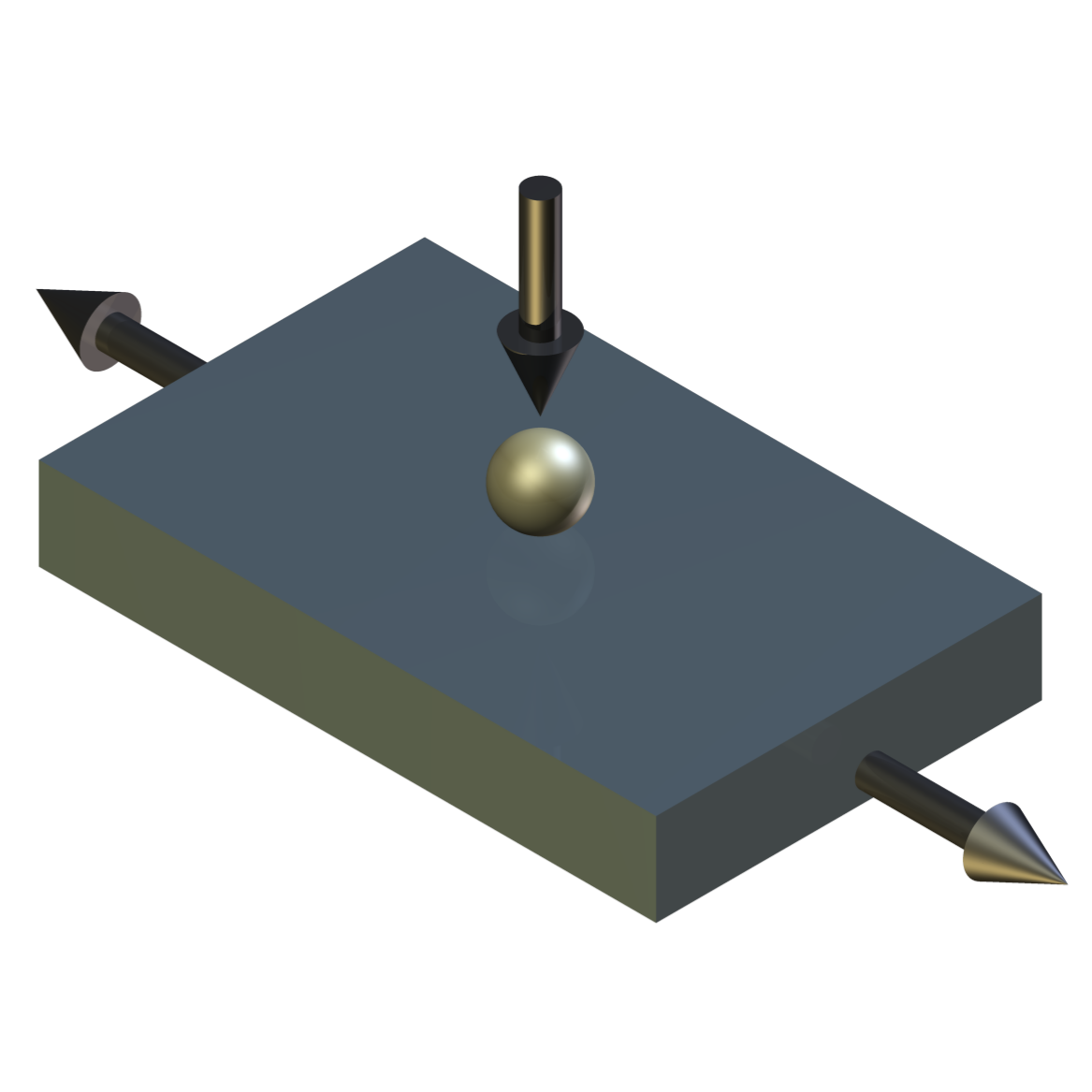

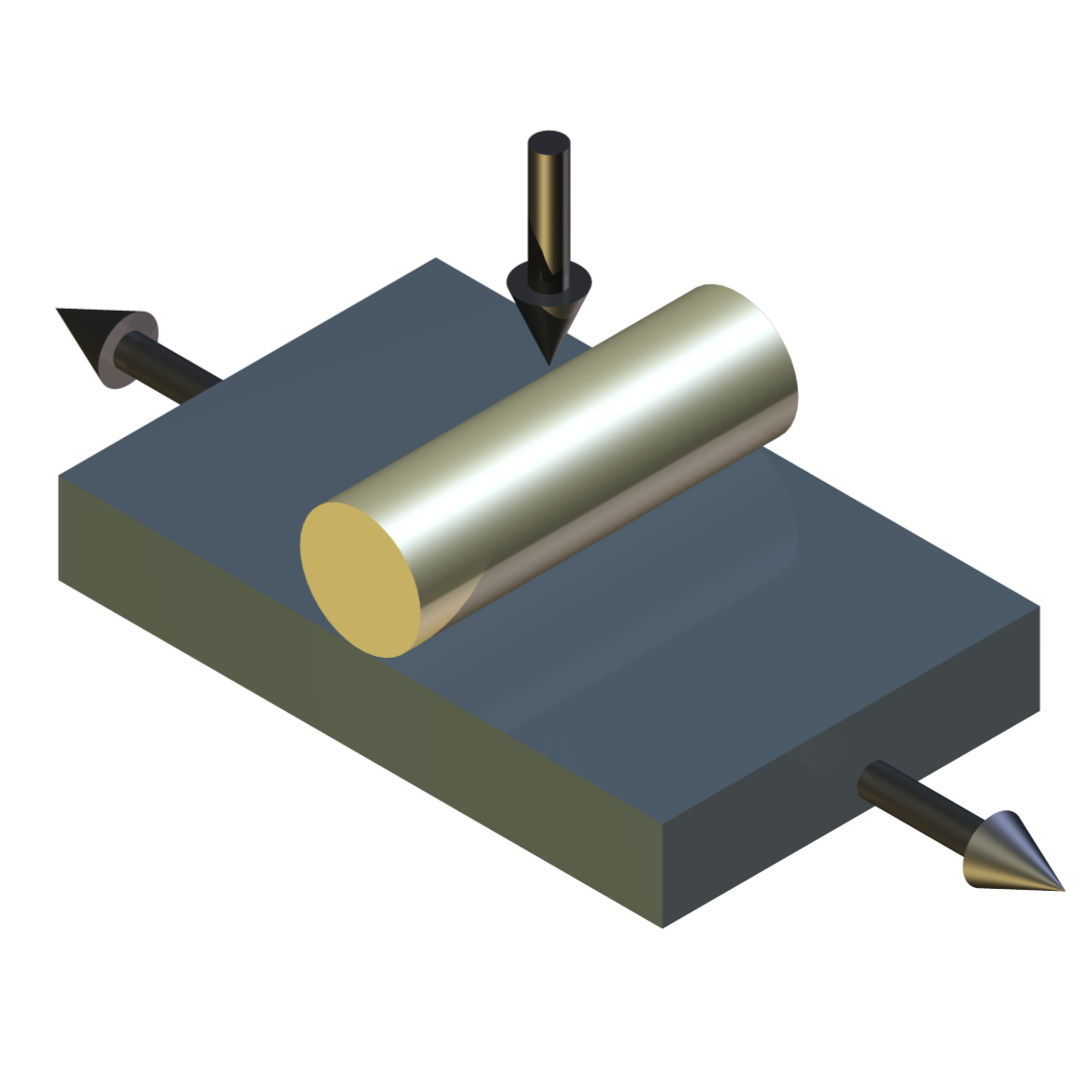

Normal Load: 10 to 1,000N Signal Conditioning: Strain Gauge Amplifier Module Friction Force Range: 250 N Signal Conditioning: Strain Gauge Amplifier Module RMS/DC Converter Module Wear: Linear Potentiometer Range: 2 mm Resolution: 0.5 µm Specimen Holder: 8 mm and 5.5 mm diameter pins Optional Holders: 10 mm and 6 mm diameter balls Interface: USB Serial Link Interface Module Software: COMPEND 2000 Motor: a.c. Vector Motor 0.55 kW Contact Configurations: Pin on Plate Ball on Plate Temperature Range: Ambient to 200°C Heating Power: 800 W Temperature sensor: k-type thermocouple Maximum Stroke: 50 mm Maximum Frequency: 5 Hz Maximum Frequency @ Maximum Stroke: 2 Hz @ 50 mm Automatically Controlled Parameters Frequency Test Duration Manually Controlled Parameters Load Reciprocating Stroke Length Measured Parameters Friction Load Temperature Wear Frequency Number of Cycles Test Duration Friction Coefficient Sliding Distance Services Electricity: 220/240V, single phase, 50 Hz, 3 kW 110/120 V, single phase, 60 Hz, 3 kW -

Download the Machine Leaflet