-

Description

The TE 92 HT High Temperature Four Ball Tester is a versatile test machine for research and development work on materials and lubricants for Dry Tests up to 600°C. With axial loading and an open test platform, the machine can accommodate multiple test geometries.

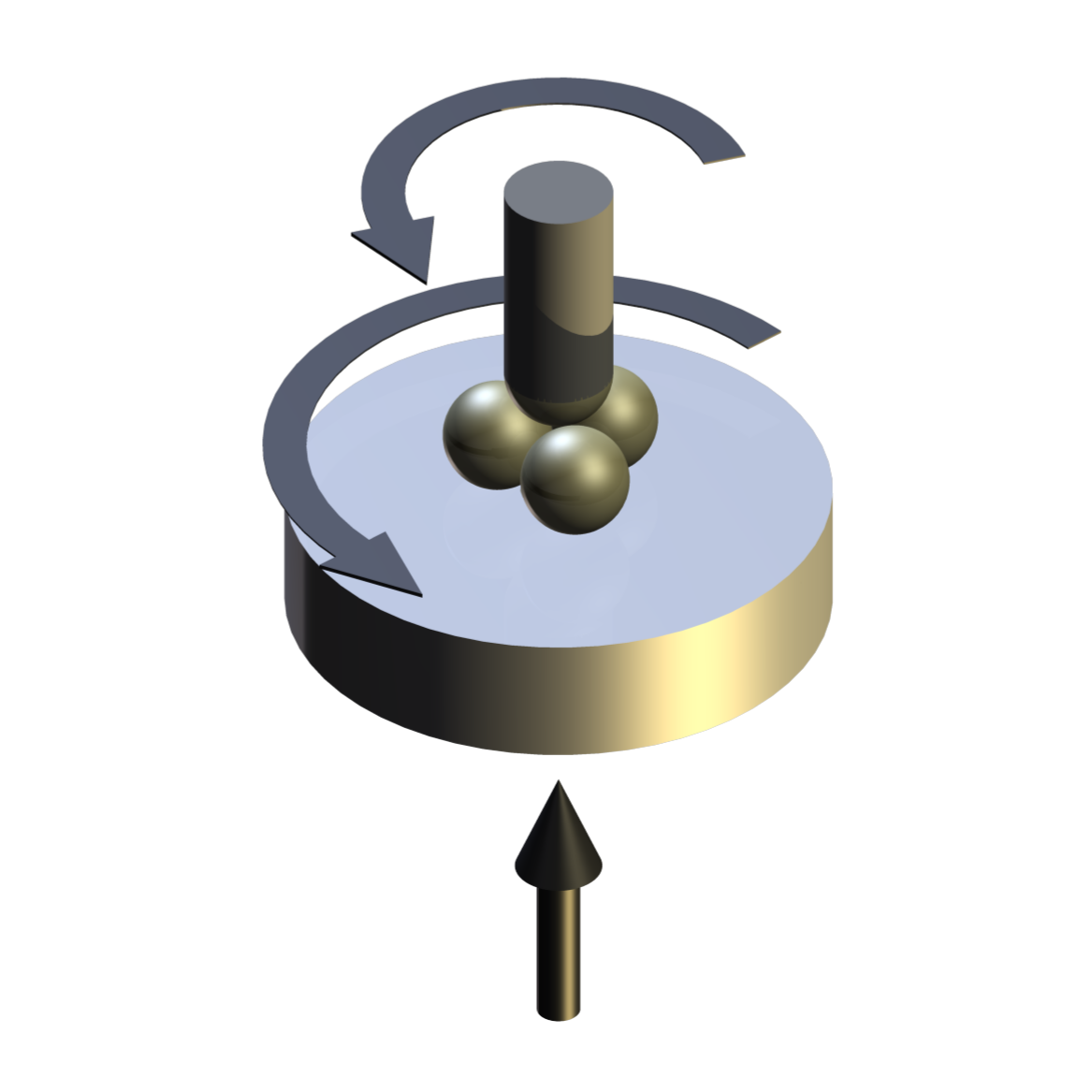

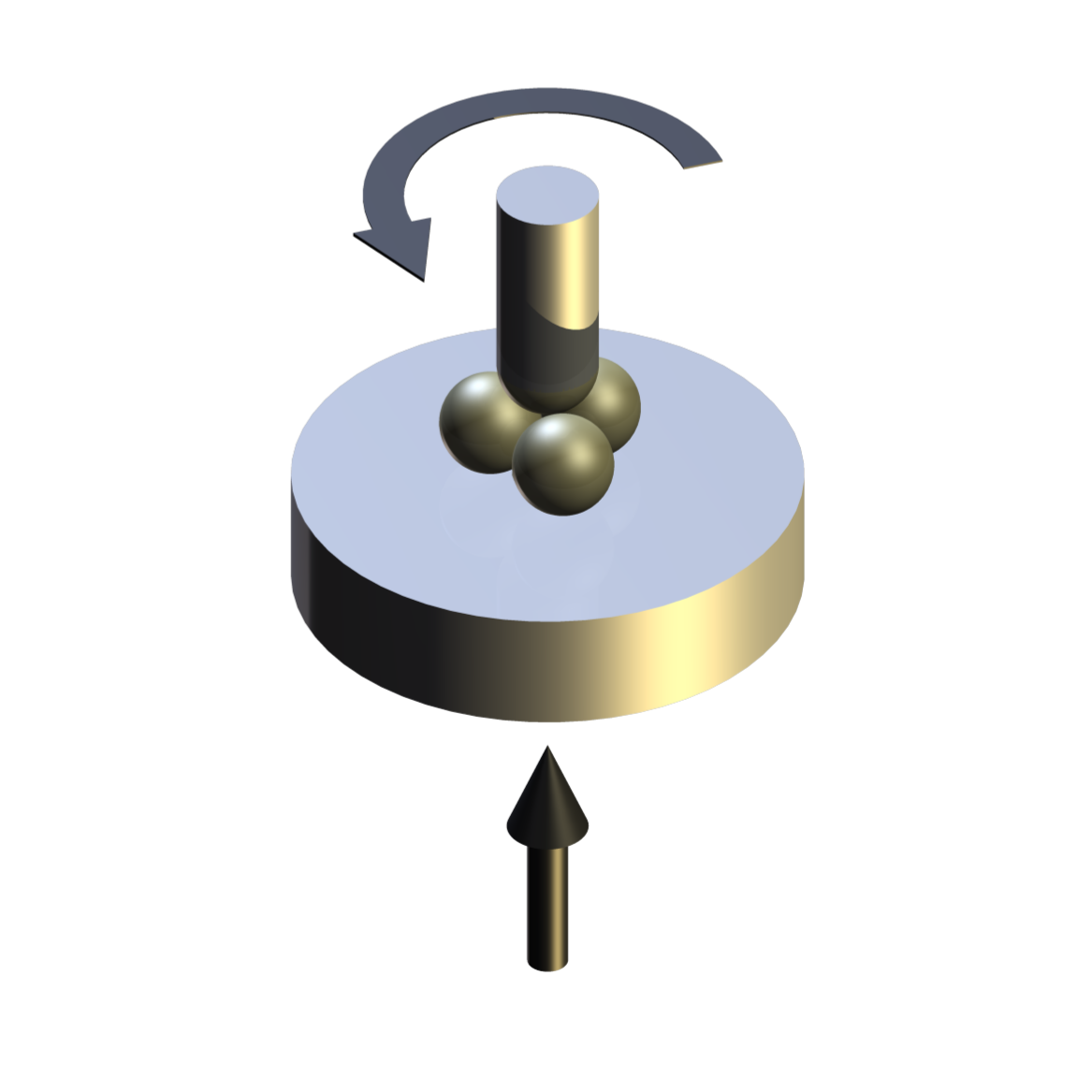

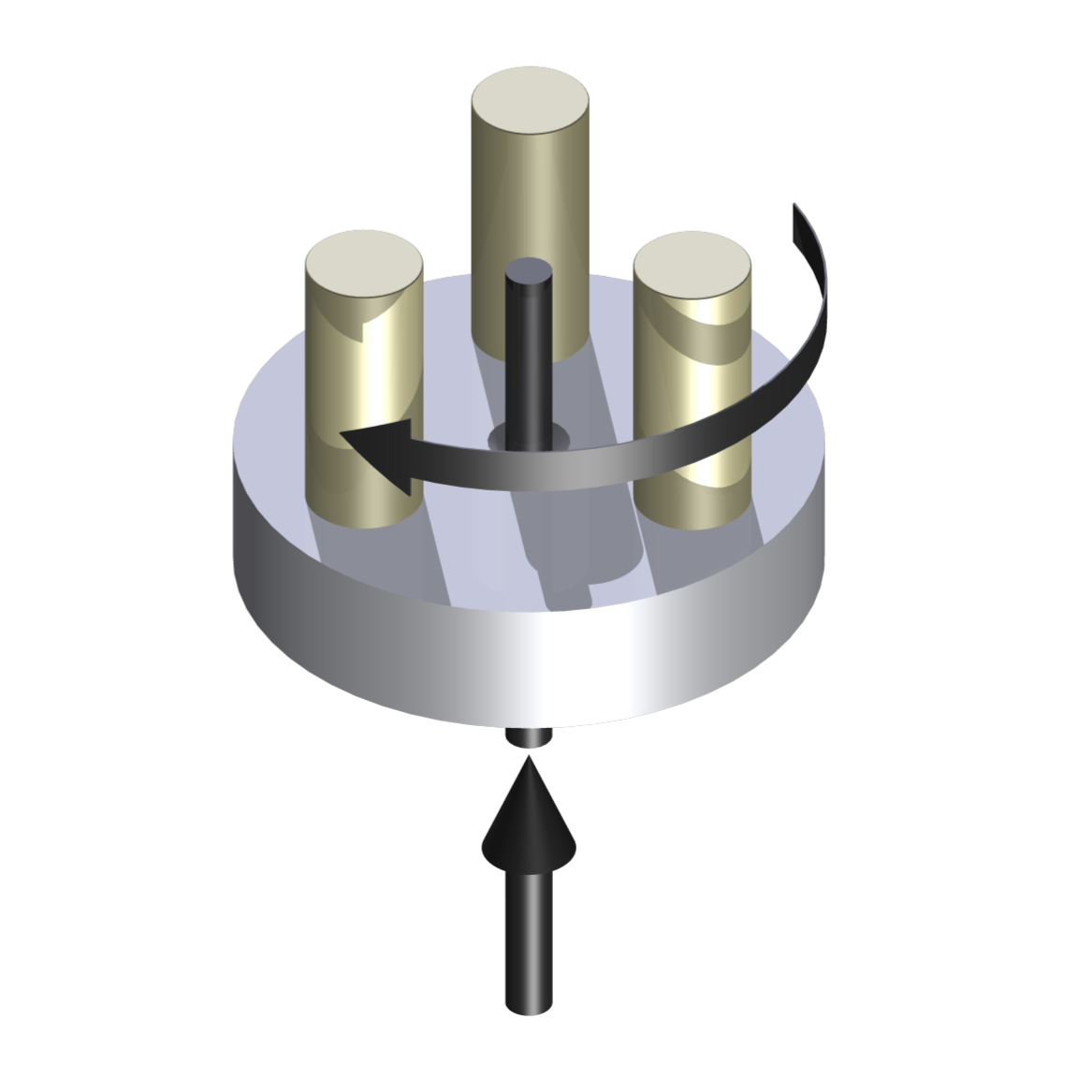

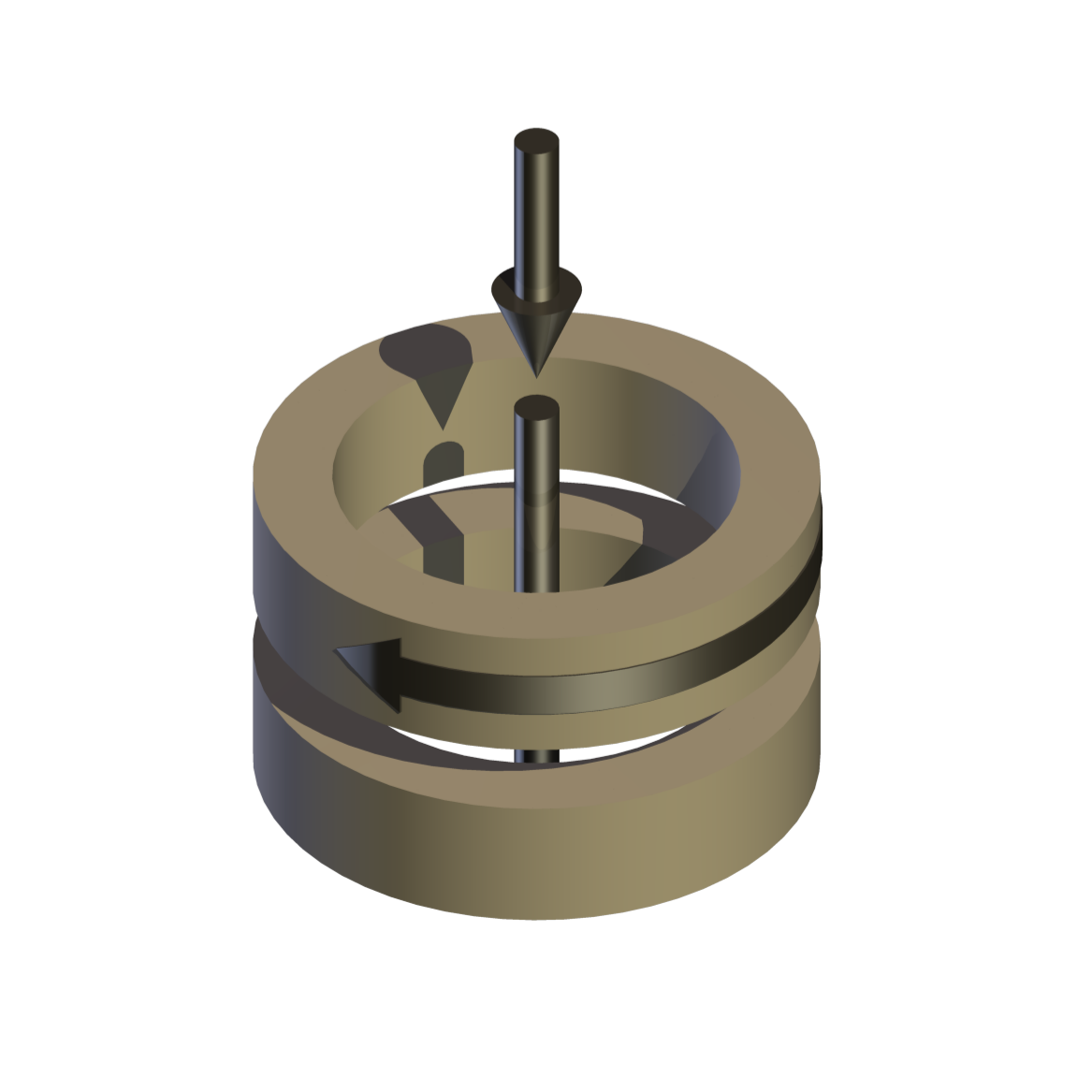

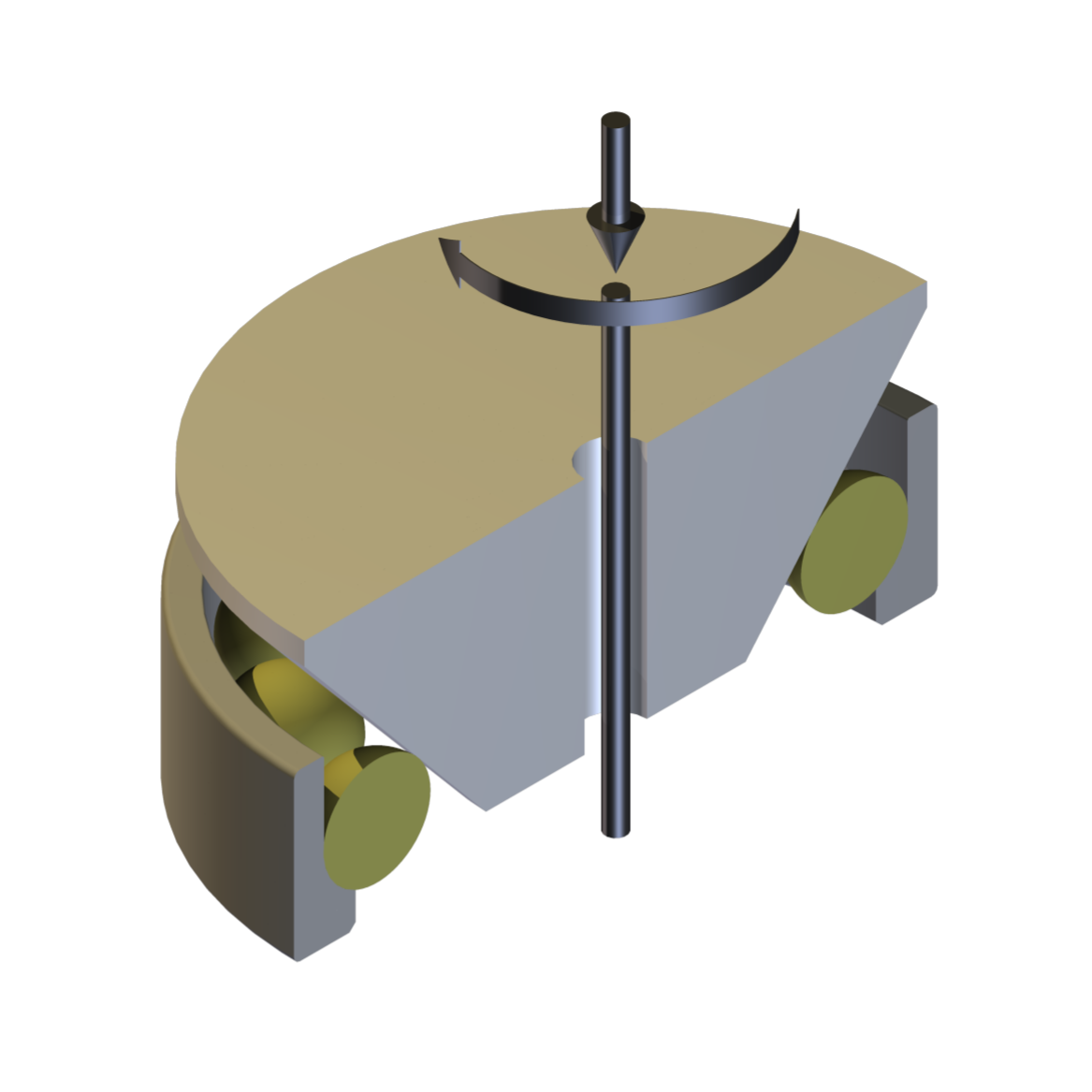

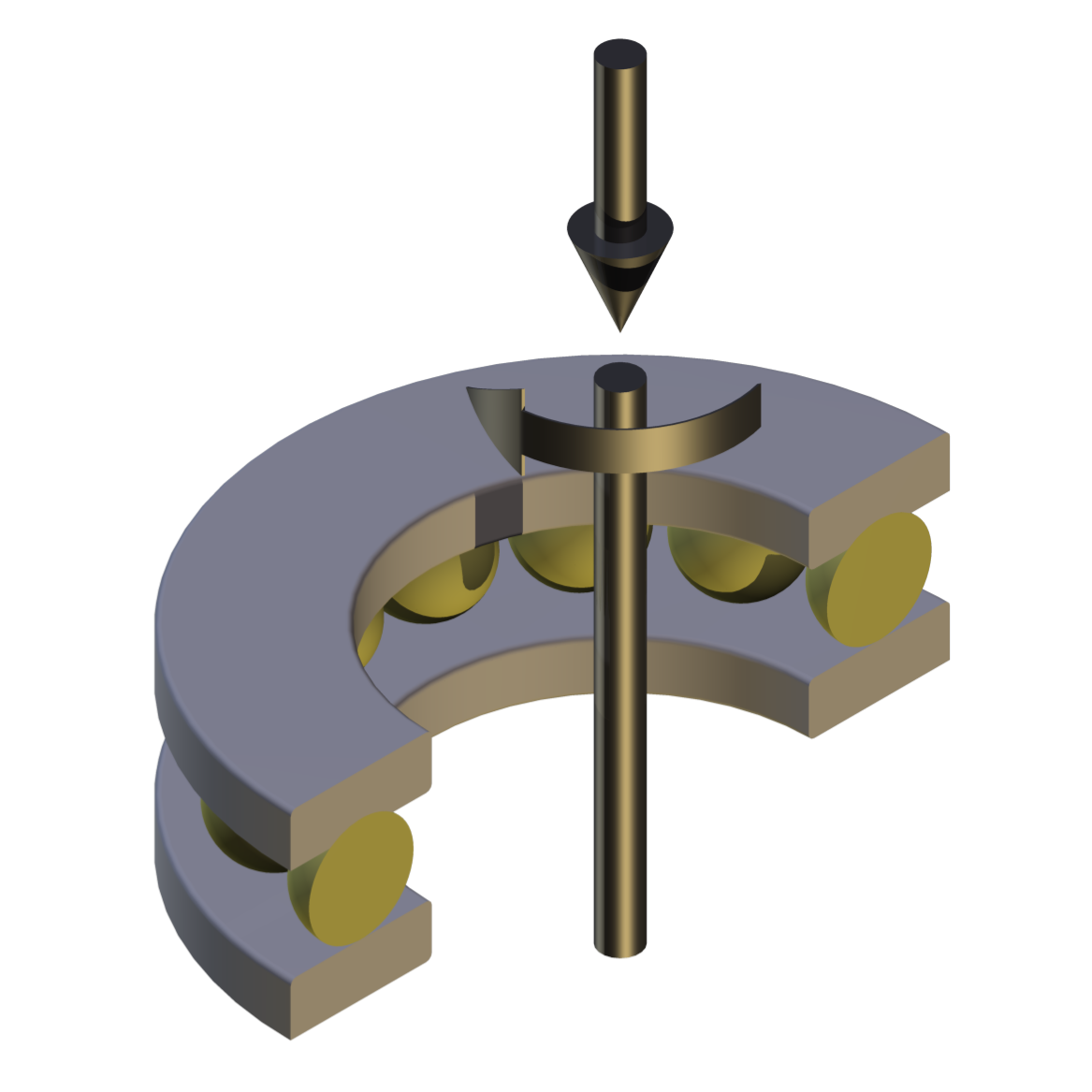

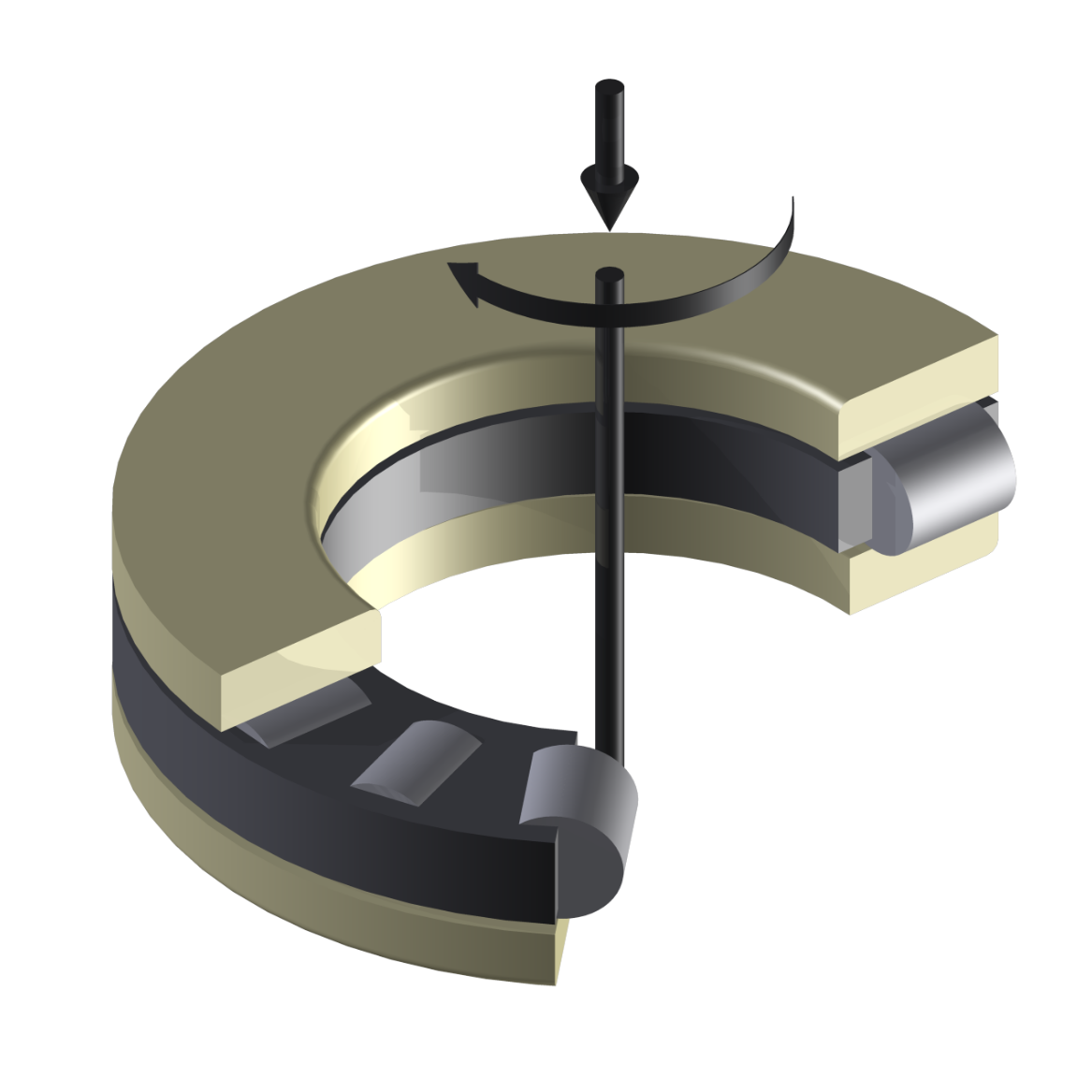

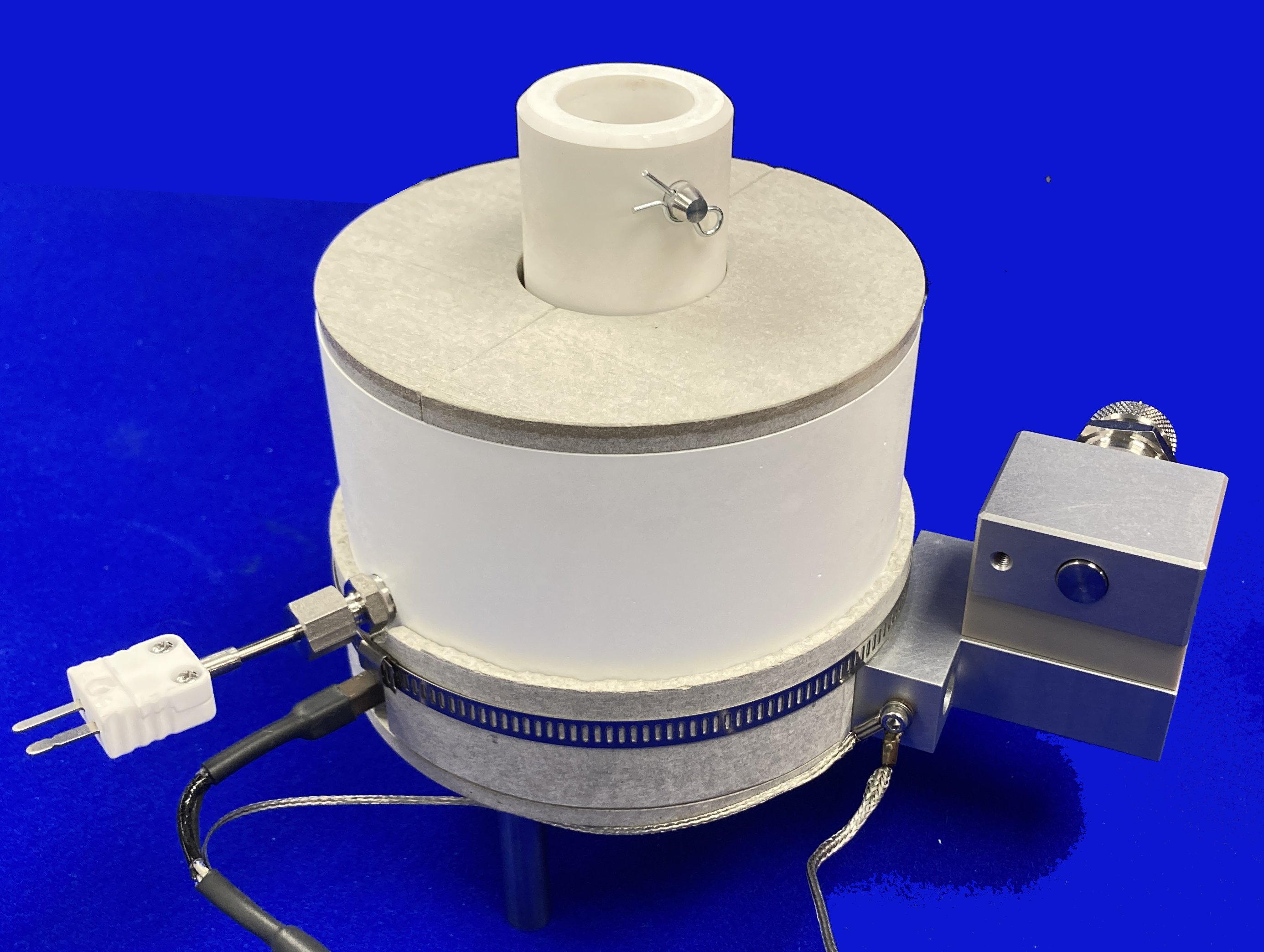

This is a high temperature specimen mounting for dry tests using either three pin-on-disc or thrust washer tooling.

Standard speed machine with 2.2 kW motor, single-phase supply and timing belt drive and torque limiter for speeds from 0 to 3,000 rpm and Poly-V belt drive for speeds 0 to 6,000 rpm. The test spindle main bearing is a taper roller bearing and the maximum design speed is 6,000 rpm.Load and Torque Measurement

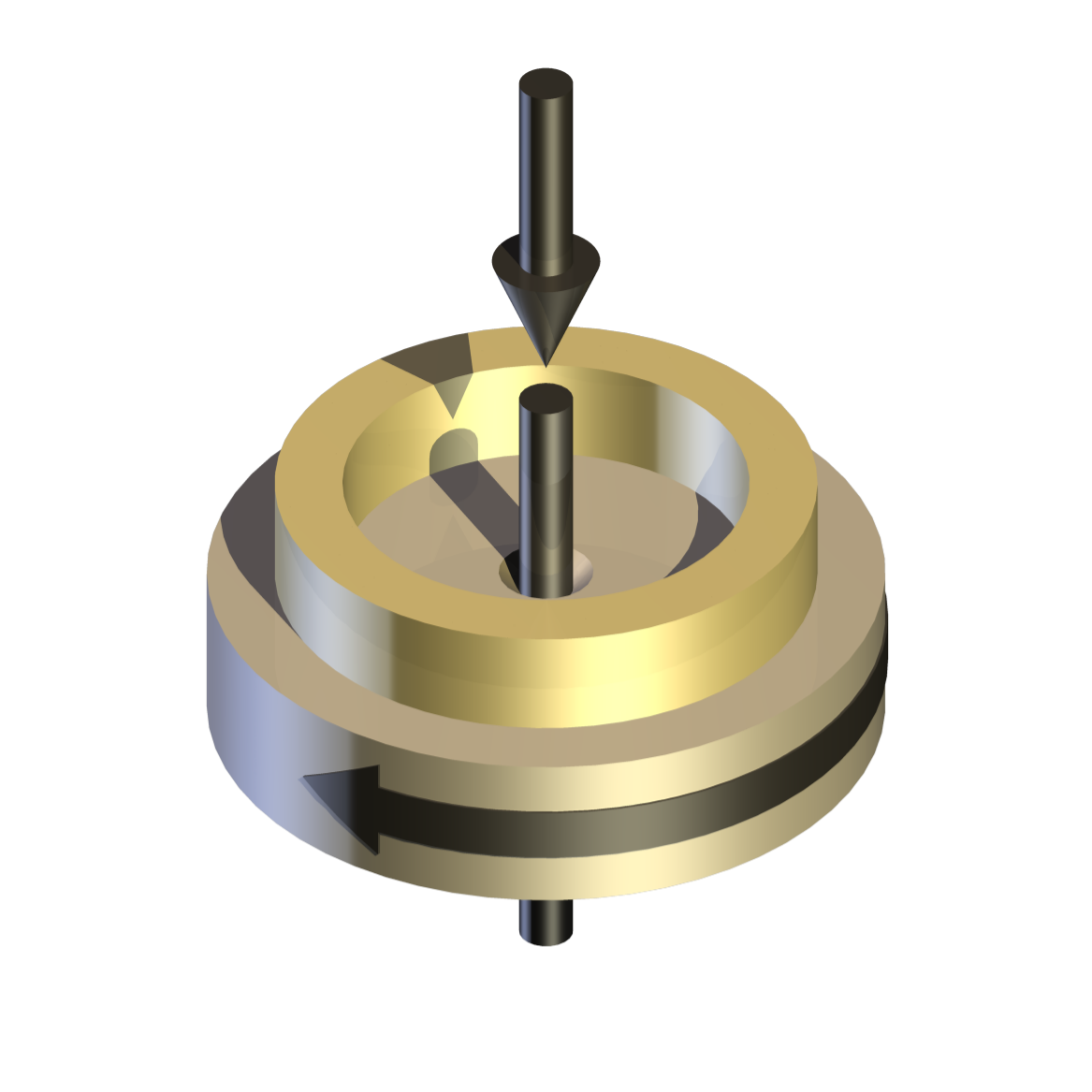

Test adapters are mounted on a cross beam with linear bearings mounted on the machine columns, loaded from underneath by a pneumatic bellows with an in-line force transducer for measurement and control of load. There are two interchangeable loading assemblies TE 92/1 and TE 92/2, providing a 500:1 turn-down ratio on load.

The test adapters are placed on a thrust bearing that permits free rotation under the influence of the frictional torque, which is resisted by a strain gauge force transducer

Temperature Measurement

Thermocouples are located in the test adapters to measure the temperature of the test sample (either material or lubricant) and this measurement is used as the feedback for software PID temperature control.

Vibration Measurement

A piezo-electric sensor is provided to monitor vibration. The sensitivity of the detection circuit is adjustable by the operator. A sudden rise in vibration level, caused, for example, by pitting damage in a rolling contact fatigue test, will trip the circuit and stop the motor.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface. Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats

-

Technical Specifications

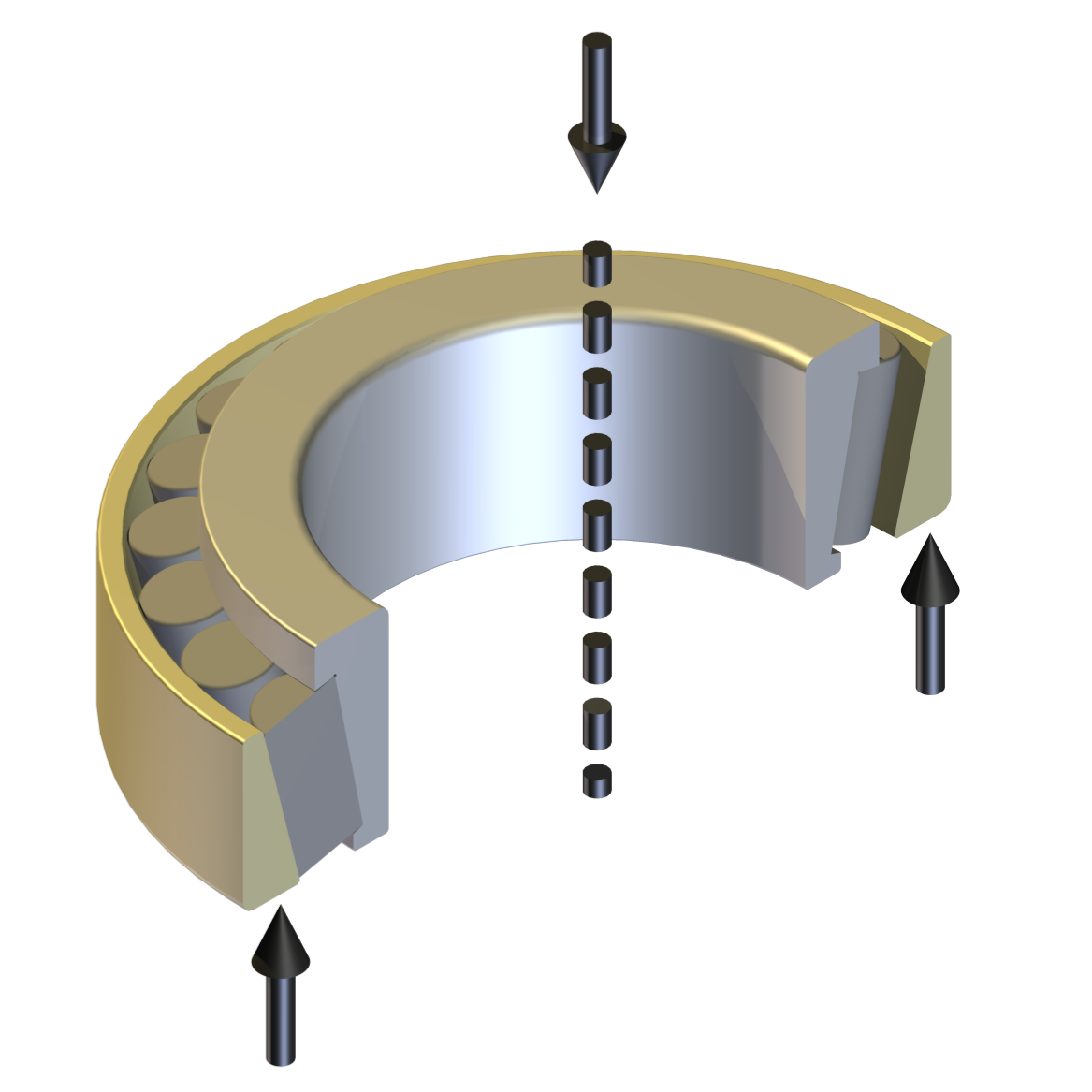

TE 92 HT TE 92HS Rotational Speed: 30 to 3,000 rpm 30 to 3,000 rpm 100 to 10,000 rpm Spindle Bearing Load: 10,000 N @ 3,000 rpm 10,000 N @ 3,000 rpm 4,000 N @ 10,000 rpm Maximum Spindle Speed: 6,000 rpm 10,000 rpm Torque Capacity: 14 Nm @ 30 to 1500 rpm 14 Nm @ 30 to 1500 rpm 7 Nm @ 3,000 rpm 7 Nm @ 3,000 rpm 2.1 Nm @ 10,000 rpm Motor: 2.2 kW ac @ 1,500 rpm 2.2 kW ac @ 1,500 rpm 100% overload for 30 seconds 100% overload for 30 seconds Heater Block Power: 550 W Temperature Sensor: k-type thermocouple Vibration Sensor: piezo-electric Contact Resistance: Lunn-Furey Circuit Interface: USB Serial Link Interface Module Software: COMPEND 2000 TE 92 + 4 kW Upgrade TE 92HS + 4 kW Upgrade Rotational Speed: 30 to 3,000 rpm 30 to 3,000 rpm 100 to 10,000 rpm Spindle Bearing Load: 10,000 N @ 3,000 rpm 10,000 N @ 3,000 rpm 4,000 N @ 10,000 rpm Maximum Spindle Speed: 6,000 rpm 10,000 rpm Torque Capacity: 25 Nm @ 30 to 1500 rpm 25 Nm @ 30 to 1500 rpm 13 Nm @ 3,000 rpm 13 Nm @ 3,000 rpm 4 Nm @ 10,000 rpm Motor: 4 kW ac @ 1,500 rpm 4 kW ac @ 1,500 rpm 100% overload for 30 seconds 100% overload for 30 seconds Controlled Parameters Rotational Speed Temperature Load Test Duration Recorded Parameters Rotational Speed Friction Torque Contact Resistance Temperatures Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance TE 92/1 Low Load Actuator Assembly Load Range: 20 to 1,000 N TE 92/2 High Load Actuator Assembly Load Range: 200 to 10,000 N TE 92/FOUR Heater Pad and Ball Collet for Four Ball Tests Ball Size: 12.7 mm (0.5″) Maximum Temperature: 200°C TE 92/FOUR/1 Sliding Four Ball Test Assembly Ball Size: 12.7 mm (0.5″) Temperature Sensor: k-type thermocouple TE 92/FOUR/2 Rolling Four Ball Test Assembly Ball Size: 12.7 mm (0.5″) Temperature Sensor: k-type thermocouple TE 92/AREA-L Heated Test Bath & Shaft Hub for Lubricated Tests Reservoir Capacity: 500 ml Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C Compatible Tooling: TE 92/AREA/1,2,3,4,5 & 6 TE 92/AREA-D Specimen Mount with Capacitance Wear Sensor & Shaft Hub for Dry Tests Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 600°C Resolution: 0.2 microns Compatible Tooling: TE 92/AREA/1 & 2 TE 92/AREA-H Specimen Mount & Shaft Hub for Dry Tests up to 600°C Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 600°C Compatible Tooling: TE 92/AREA/1 & 2 TE 92/AREA/1 Three Pin on Disc Tooling Contact Configuration: Rotating Disc on Three Pins Ball Specimen Diameter: 6 mm Mean Friction Diameter: 40, 50 & 60 mm Small Pin Diameter: 4 mm Mean Friction Diameter: 40, 50 & 60 mm Large Pin Diameter: 8 mm Mean Friction Diameter: 50 mm TE 92/AREA/2 ASTM D3702 Thrust Washer Specimen Tooling Contact Configuration: Thrust Washer 1.125″ O/D according to ASTM D 3702 2″ O/D according to ASTM D 3702 User specified non-standard TE 92/AREA/3 LVFA (small) Specimen Tooling Contact Configuration: Thrust Washer (LVFA small) Friction Sample Inner Diameter: 20 mm Friction Sample Outer Diameter: 26 mm Counter-face Outer Diameter: 37 mm TE 92/AREA/4 Vane Pump Specimen Tooling Contact Configuration: Three Vane on Disc Vane Width: 15.5 mm Vane Thickness: 2 mm Mean Friction Diameter: 31.5 mm Counter-face Outer Diameter: 50 mm TE 92/AREA/5 Suzuki Test Specimen Tooling Contact Configuration: Thrust Washer Rotating Sample Inner Diameter: 20 mm Rotating Sample Outer Diameter: 30 mm TE 92/AREA/6 Three Pad Thrust Bearing (Stribeck) Tooling Contact Configuration: Ring on Taper Land/Flat Land Pads Ring Internal Diameter: 60 mm Ring External Diameter: 92 mm Ring Thickness: 9 mm Taper Land Length: 5 mm Taper Land Width: 10 mm Taper Land Angle: 0.5 degrees Flat Land Length: 5 mm Flat Land Width: 10 mm User specified non-standard TE 92/RCF Self-aligning Heated Reservoir for Rolling Contact Fatigue Tests Reservoir Capacity: 500 ml Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C Compatible Tooling: TE 92/RCF/1,2 & 3 TE 92/RCF/1 Cone on Angular Contact Bearing Tooling Contact Configuration: Cone on ball race – pure rolling Cone: 40 degree included angle Rolling Bearing: SKF 7206 cage and lower race Balls: silicon nitride Maximum Contact Stress: 5.5 GPa Maximum Speed: 3,000 rpm (TE 92) 10,000 rpm (TE 92HS) TE 92/RCF/2 Ball Thrust Bearing on Disc Tooling Thrust Bearing: Size 51208 Disc Diameter: 68 mm Maximum Speed: 6,000 rpm TE 92/RCF/3 Roller Thrust Bearing on Disc Tooling Thrust Bearing: Size 81208 TN Disc Diameter: 68 mm Maximum Speed: 6,000 rpm TE 92/RCF/E Electrical Discharge Machining (EDM) Test System Applied Voltage: 0 to 24 volts Commutator: 2 pulses per revolution TE 92/RCF/2/E Ball Thrust Bearing Tooling for EDM Tests Thrust Bearing: Size 51208 Maximum Speed: 6,000 rpm TE 92/RCF/3/E Roller Thrust Bearing Tooling for EDM Tests Thrust Bearing: Size 81208 TN Maximum Speed: 6,000 rpm TE 92/RCF/T10 In-line Rolling Friction Torque Transducer Axial Load: 1 kN Torque: 10 Nm TE 92/RCF/T25 In-line Rolling Friction Torque Transducer Axial Load: 2.5 kN Torque: 25 Nm TE 92/RCF/T50 In-line Rolling Friction Torque Transducer Axial Load: 5 kN Torque: 50 Nm TE 92/RCF/T100 In-line Rolling Friction Torque Transducer Axial Load: 10 kN Torque: 100 Nm TE 92/PV Pin on Vee Block/Block on Ring Adapter Contact Configuration: Pin on vee block Block on ring User specified custom tooling Pin on Vee Specimens: Standard Falex specimens Ring Specimen: Max dia 35 mm x max width 10 mm Maximum Load: 20,000 N Rotational Speed: 60 to 1,840 rpm (direct drive) 60 to 3,000 rpm (direct drive) Torque Capacity: 7.4 Nm @ 60 to 1,840 rpm (direct drive) 4.5 Nm @ 3,000 rpm (direct drive) Heater Bath Temperature: 200 °C TE 92/LL Precision Low Load Adapter Load Range: 1 to 1,000 N TE 92/EC Electro-chemical Cell & Potentiostat Contact Configuration: Three balls rotating on fixed disc Contact Configuration: Three pins rotating on fixed disc Load Range: 1 to 1,000 N Potentiostat: Ref 600 Potentiostat/Galvanostat/ZRA TE 92/SA/1 Special Adapter – Three Station Ring on Liner Adapter Contact Configuration: Line Contact Maximum Ring Sample Load: 500 N Maximum Liner Surface Temperature: 200 °C TE 92/SA/2 Special Adapter – Three Ball on Rod Rolling Contact Fatigue Standard Ball Diameter: 12.7 mm (1/2 inch) Standard Rod Diameter: 9.52 mm (3/8 inch) Cone Included Angle: 45 degrees Stress Cycles: 2.3828 per revolution Maximum Contact Pressure (steel on steel): 5.5 GPa TE 92/SA/3 Special Adapter – KRL Shear Test Adapter (DIN 51350 Part 6) Bearing: SKF 32008 X/Q Temperature Sensor: k-type thermocouple Sump Capacity: 35 litres Heater Power: 3 kW Pump Flow: 9 litre/minute at zero head TE 92/SA/4 Cone on Elastomer Ring Test Adapter Cone Angle: 45 degrees Ring Internal Diameter: 42 mm Ring Outside Diameter: 70 mm Ring Thickness: 6 mm TE 92/SA/5 Orbital Spherical Bearing Test Adapter Maximum Ball Diameter: 50 mm Maximum machine axial load: 10 kN Maximum Tilt Angle: 15° Maximum Speed: 120 rpm TE 92/SA/6 Lip Seal Friction Test Adapter User Specified Lip Seal Inner Diameter: 38 to 68 mm TE 92/LS Circulating Lubricant Supply up to 100°C Header Tank Volume: 1.2 litres Peristaltic Pump Flow: 1 litre/minute (maximum) Heating Power: 550 W Temperature Range: ambient to 100°C TE 92/0 Oscillating Drive Adapter Oscillating Motion: +/-10 degrees at 25 Hz +/-15 degrees at 20 Hz +/-20 degrees at 18 Hz +/-25 degrees at 15 Hz +/-35 degrees at 10 Hz +/-45 degrees at 8 Hz TE 92/HSD High Speed Data Acquisition Option High Speed Interface: USB Resolution: 16 bit Number of Input Channels: 6 Maximum Data Rate: Six channels at 50 kHz TE 92/DM Digital Microscope with Camera & PC Image Capture Software Magnification: x 40 Graticule: range 2 mm with 0.01 mm divisions range 4 mm with 0.02 mm divisions Services Electricity – TE 92 & TE 92HS 220/240V, single phase, 220/240V, single phase, 50/60 Hz, 7.5 kW 50/60 Hz, 7.5 kW Electricity – TE 92 & TE 92HS + 4 kW Upgrade 380/415 V, three phase, 380/415 V, three phase, 50/60 Hz, with neutral & earth 7.5 kW 50/60 Hz, with neutral & earth 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) 4 cfm at 8 bar (120 psi) Installation Floor-standing machine: 900 mm x 600 mm deep x 2000 mm 350 kg Packing Specifications: 2.2 m3, GW 550 kg -

Applications

-

Overview Videos

Machine Overview

EDM Tests

Training Videos

TE 92 Machine Training Video

Pin On Vee Adaptor Training Video

TE92/RCF/E EMD Tooling Training Video

-