-

Description

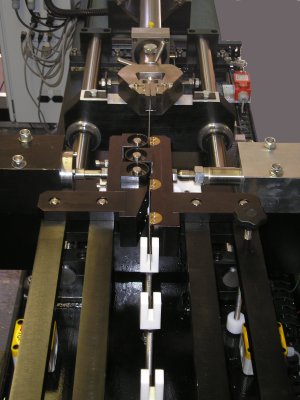

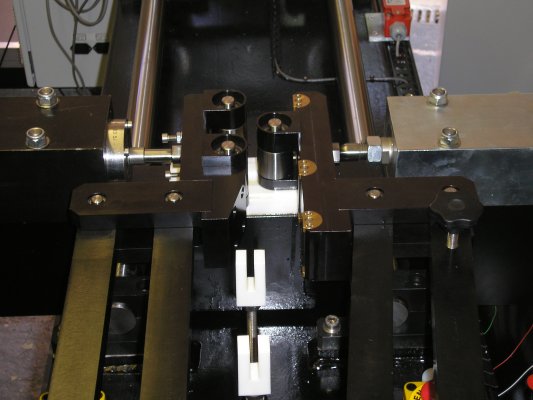

The DN 33 Draw Strip/Draw Bead Tester comprises a long stroke electro mechanical ball screw actuator mounted horizontally on a steel bed plate in line with a tooling fixture. The actuator has an integral LVDT for displacement measurement and is controlled by means of a standard a.c. vector drive with encoder feedback.

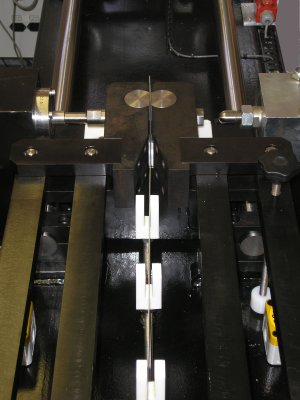

The tooling fixture comprises two articulated arms, each carrying one half of a draw tool. The arms are connected to a fixed point on the machine bed-plate by means of a force transducer, in such a way as to measure the combined drawing force on the arms. The clamping force on the draw tool is by means of a hydraulic cylinder with force transducer feedback and controlled by means of a proportional control valve.

The standard specimen is a long strip of material of up to 25 mm width, which is connected to the actuator by means of standard mechanical grips.

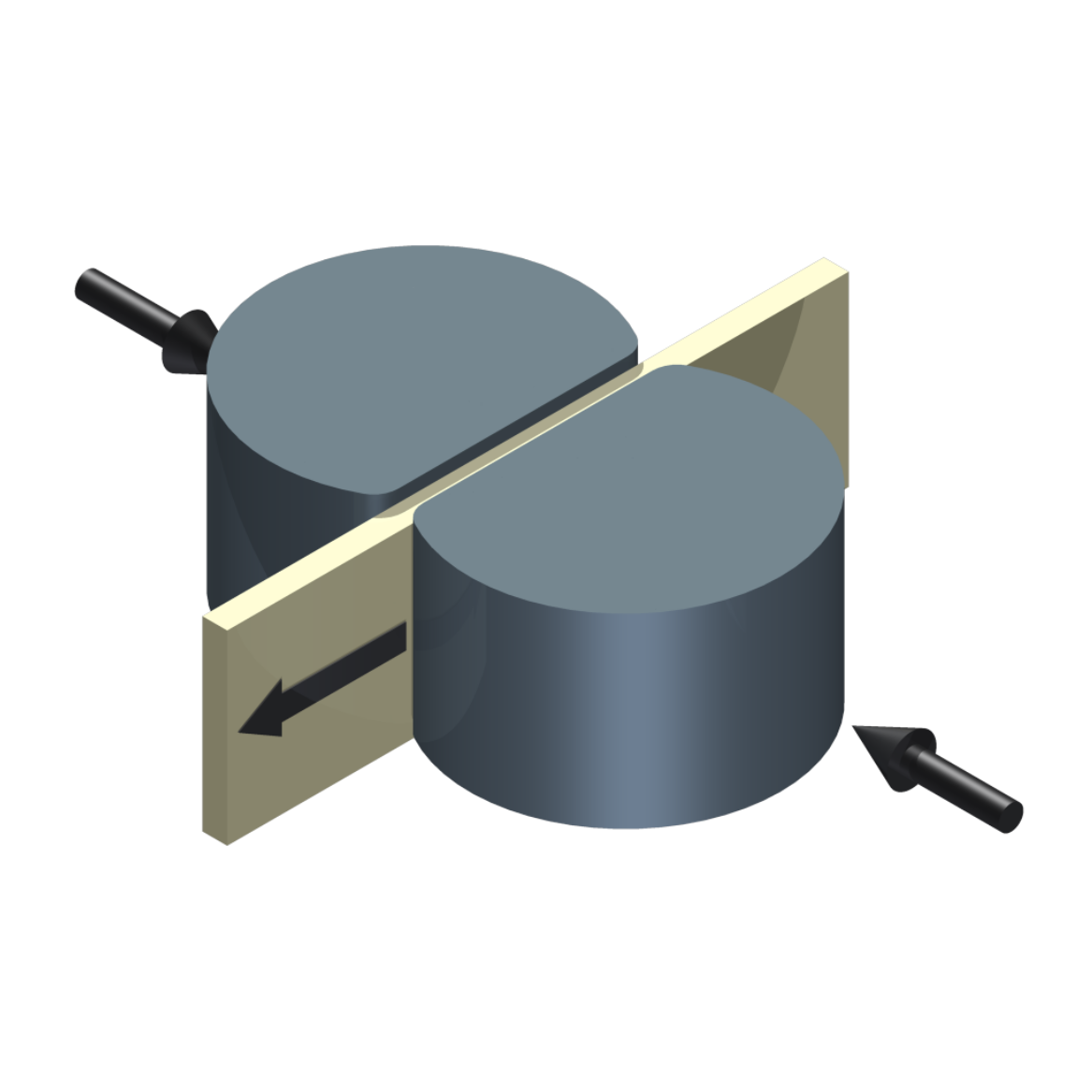

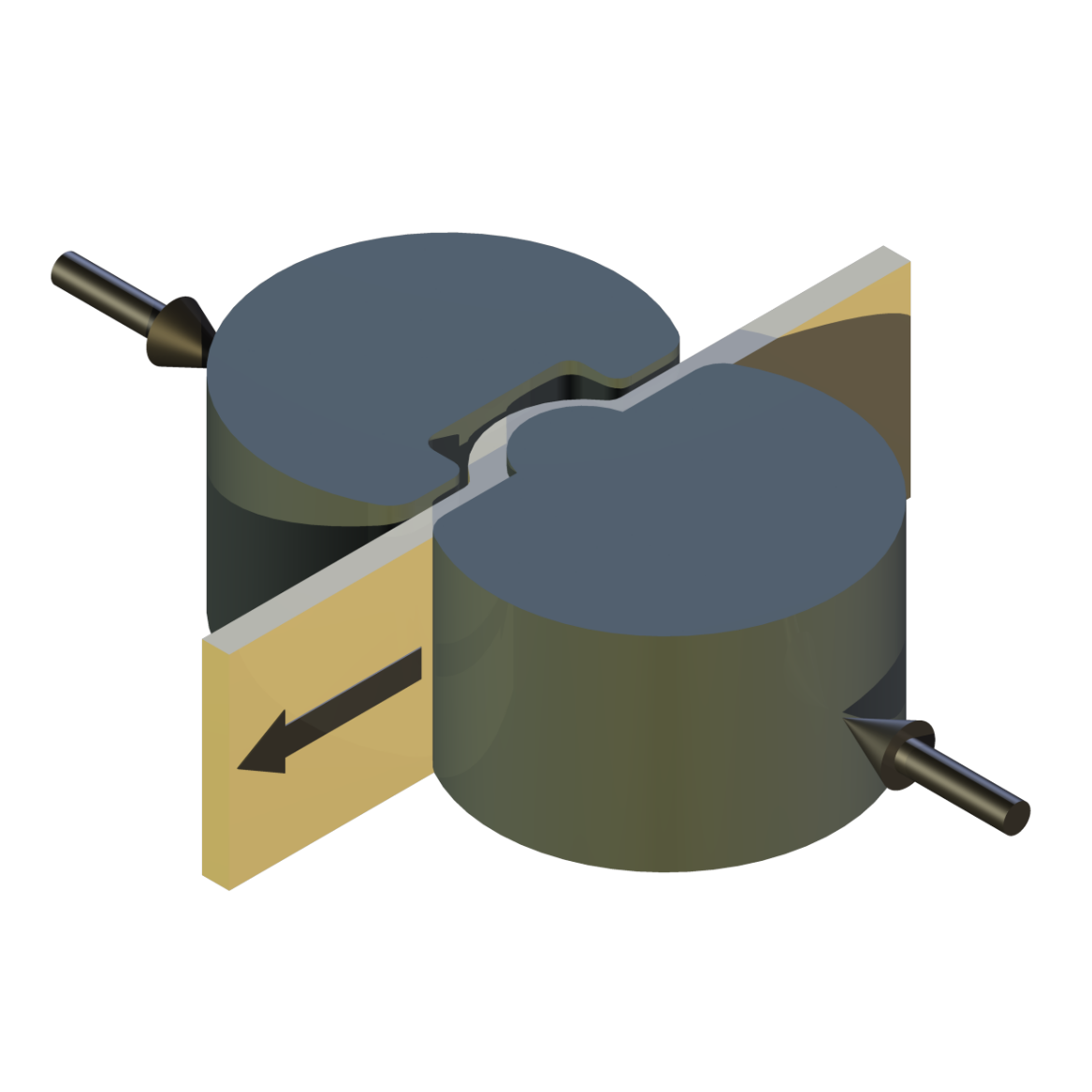

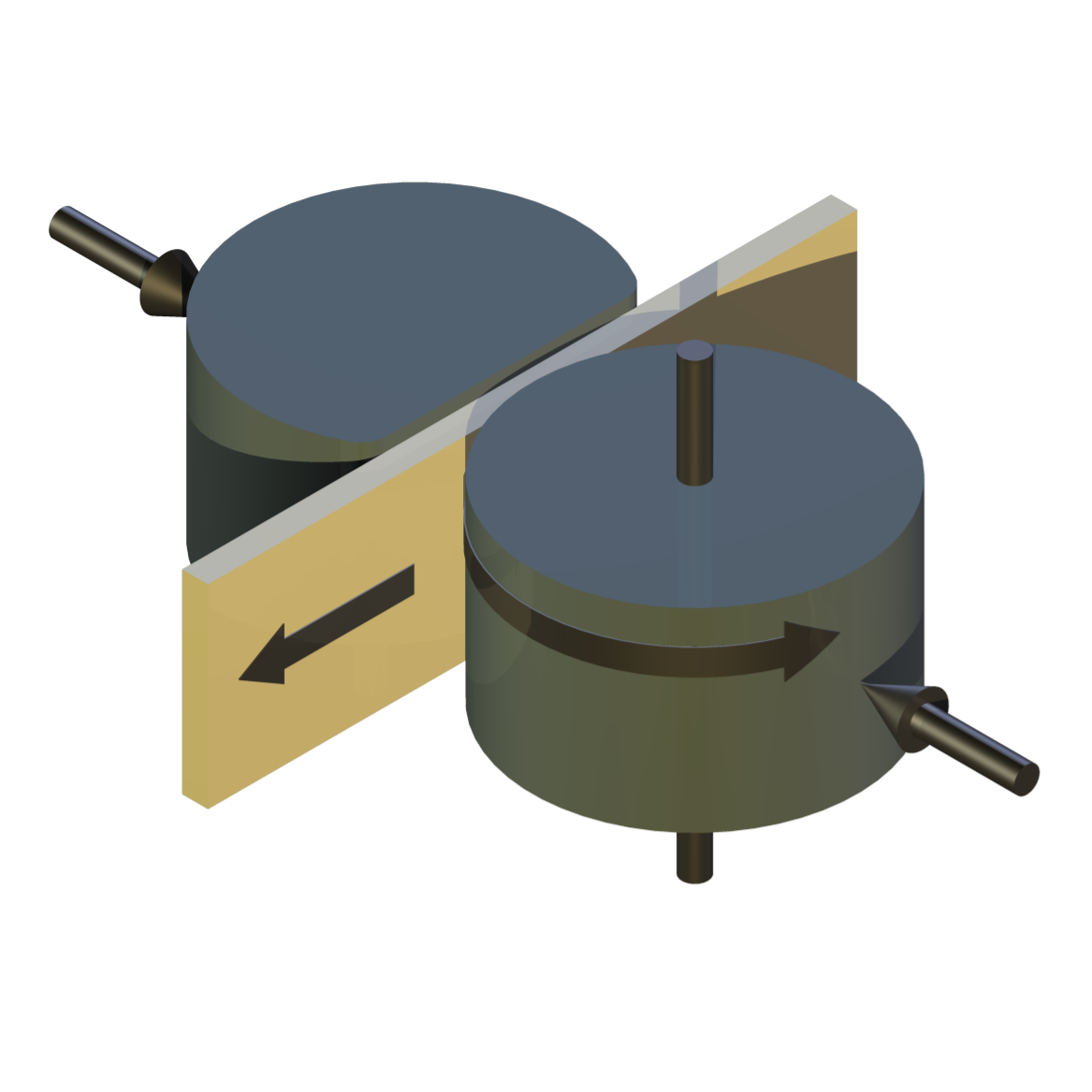

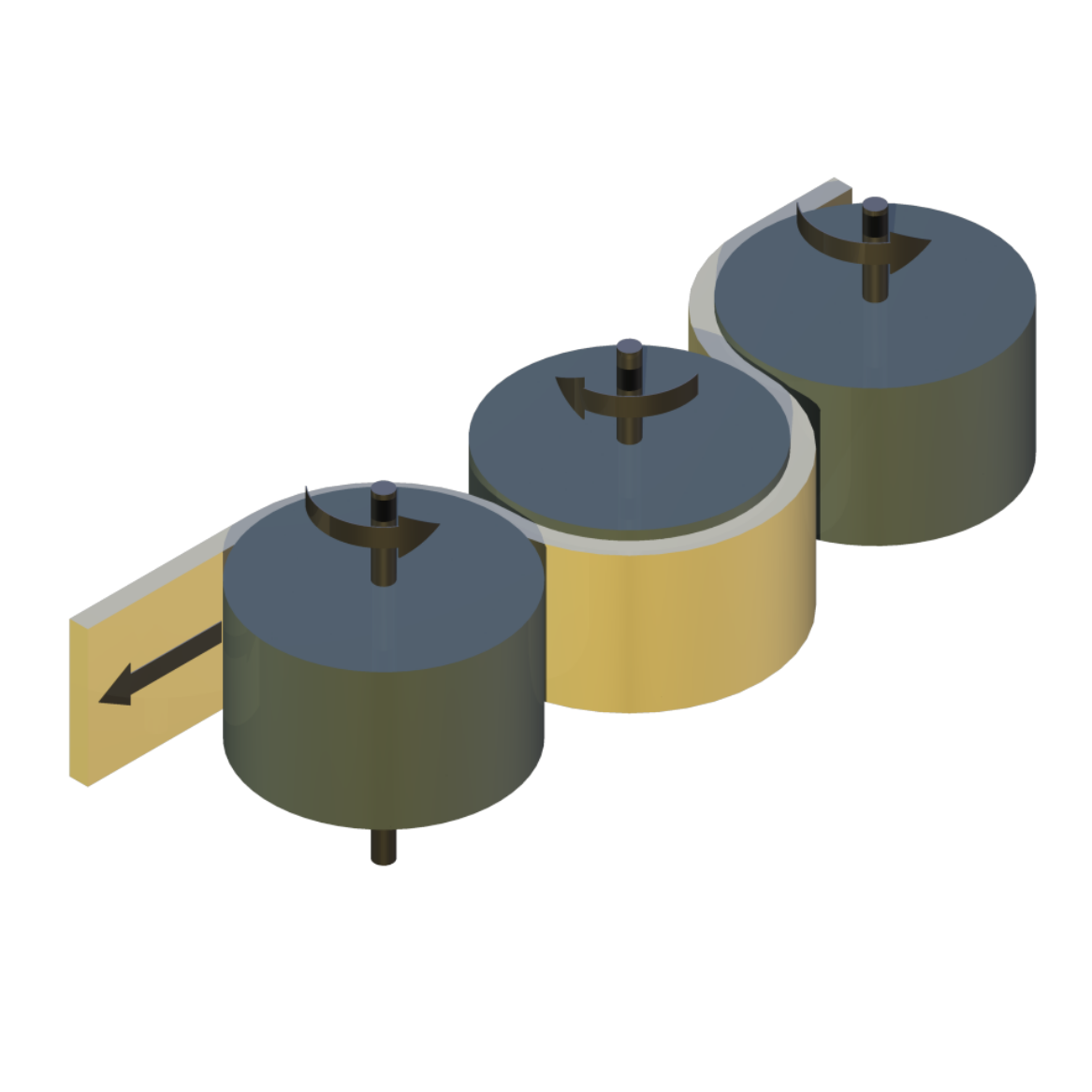

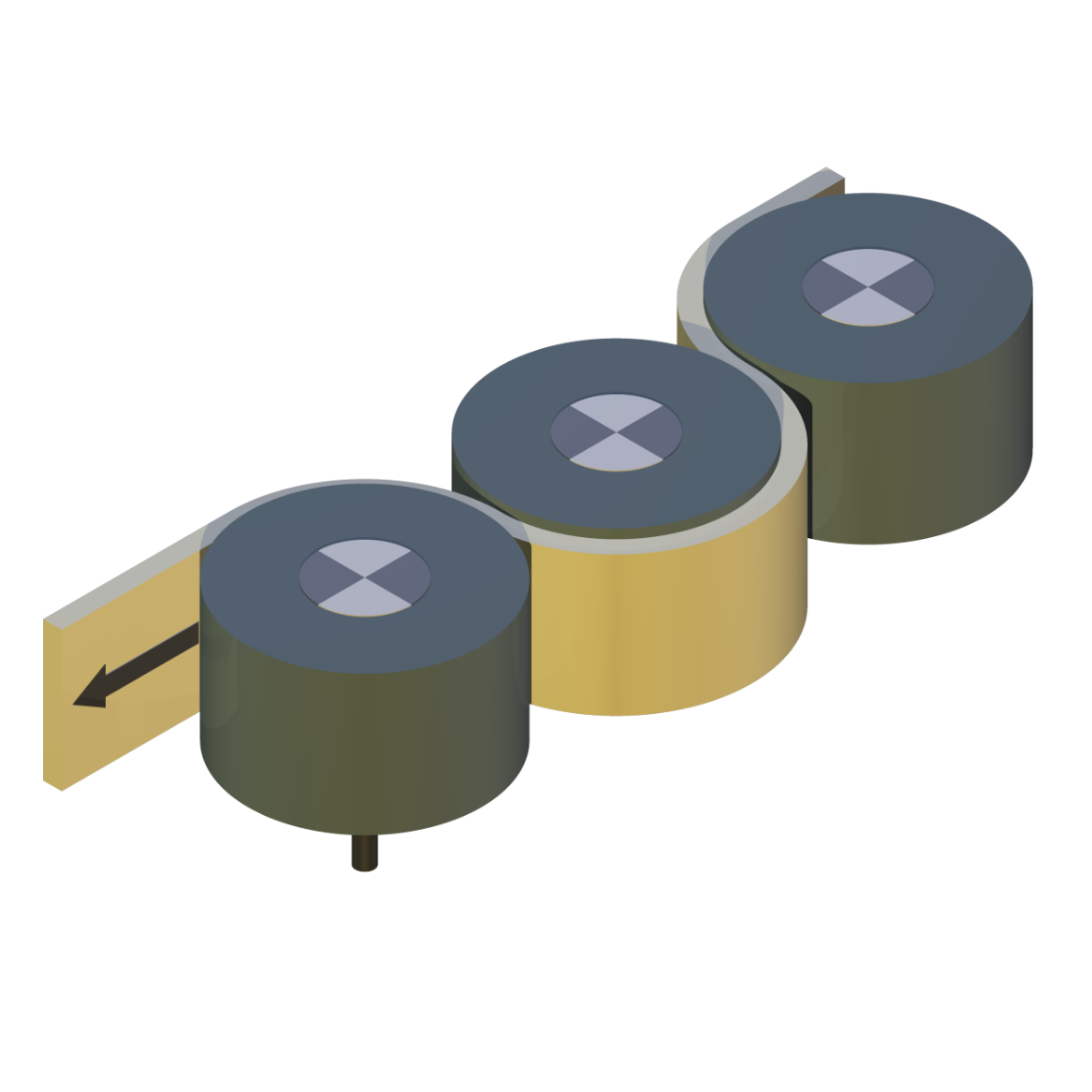

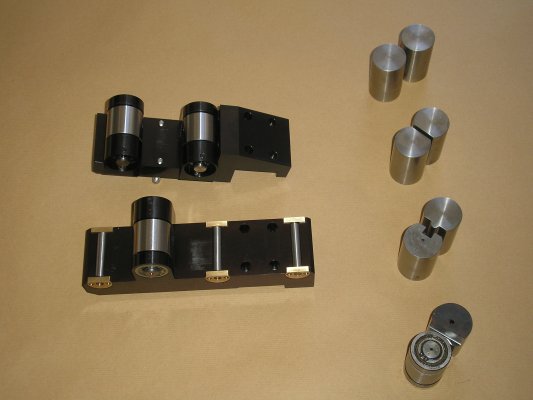

A variety of different tools may be used, providing a range of different sliding contacts including flat on flat area contact, cylinder on flat line contact and draw bead contact. In all these configurations, the friction force measured is the combined force on both surfaces. An alternative cylinder on flat line contact configuration is available in which the cylindrical tool is replaced by a roller, allowing sliding on one surface and rolling on the other.

A roller bead test assembly is also available in which the rollers may either be unclamped and allowed to roll freely, thus generating only the deformation force, or clamped, thus generating combined deformation and sliding friction force.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface. Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.

-

Technical Specifications

Drawing Speed: 200 to 2,000mm/min Speed Resolution: +/- 1% of maximum speed Maximum Clamping Force: 1 kN to 68 kN Clamping Force Load Cell: 100 kN Maximum Pulling Force: 54.8 kN (18.4 kN for a lifetime of 2500 km) Drawing Force Load Cell: 100 kN Maximum Drawing Length: 400 mm Maximum Strip Size: 525 mm x 70 mm Tool Size: 35 mm x 45 mm (typical) Tool Finish: 0.05 – 0.02 microns Ra Contact Conditions: Flat on Flat Cylinder on Flat (sliding) Cylinder on Flat (rolling) Draw Bead Fixed Bead/Roller Bead VDA Standard Flat on Flat: Length 145 mm x Width 70 mm Additional Features: Strip Heating – Ceramic Tool Heating – Cartridge Thermocouples x 2 Pyrometers x 2 Actuator: Electro-thrust Ballscrew with a.c. Servo Motor Clamping Force: Hydraulic Ram Power Pack: 2 l/min at 210 bar Interface: USB Serial Link Interface Module Software: COMPEND 2000 Automatically Controlled Parameters Drawing Speed Specimen Load Measured Parameters Drawing Speed Specimen Load Drawing Friction Force Drawing Displacement Services Electricity: 220/240V, single phase, 50 Hz, 7.5 kW 110/120 V, single phase, 60 Hz, 7.5 kW Installation Floor-standing: 900 mm wide x 600 mm deep x 1,200 mm high, 250 kg Control cabinet: 530 mm x 800 mm x 300 mm high, 20 kg -

Index Tags

-