• 3000 rpm

• Single function

• Multi-station

• Easy to Operate

• Control via PLC

Introduction

The fatigue lives of nominally identical rolling elements, tested under identical conditions, can be widely different. The principle reason for this is that bearing steels are not homogeneous. The number of repeat tests will depend on the confidence level required, but will rarely be less than ten, and will frequently be twenty, thirty or more.

Description

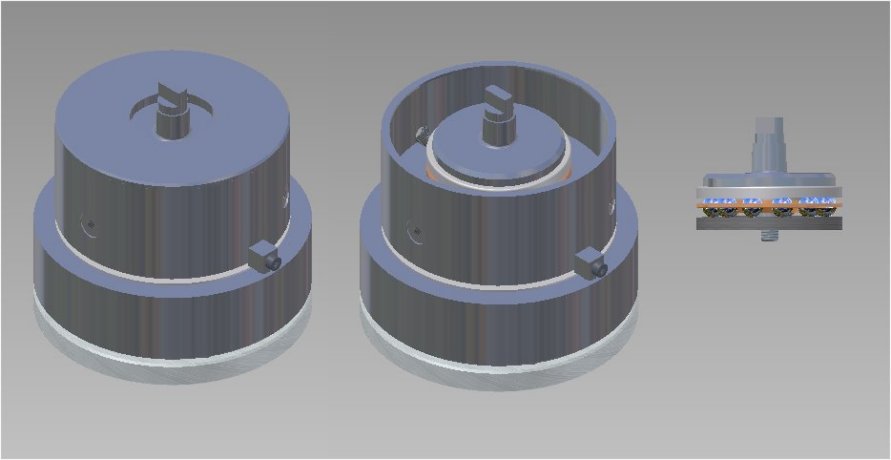

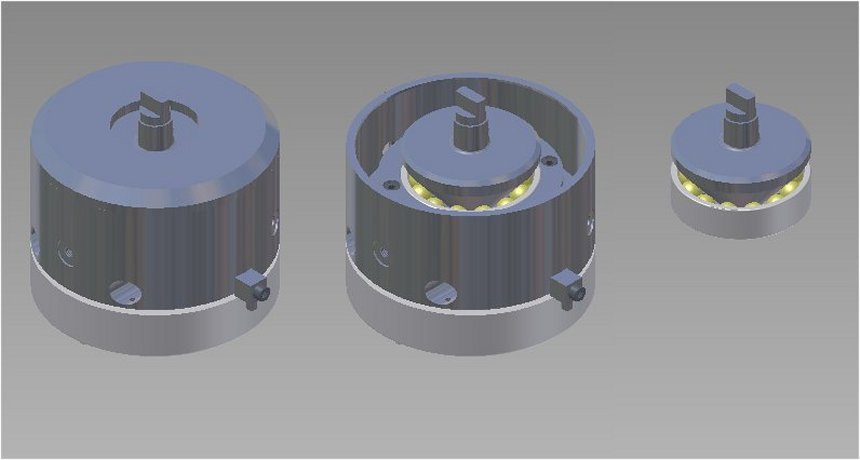

The machine is floor standing and designed to be installed either as a single unit or, more cost effectively, as a multi-unit installation, using a common pneumatic loading system, so that the same load is applied to each test station.

Each station incorporates a PLC, with inputs via touch-screen, for independent control of motor speed and test assembly temperature, plus a vibration sensor and adjustable level trigger circuit, for detecting rolling contact fatigue and stopping the motor.

Load actuators are connected in parallel to a common pneumatic supply, with a manually set precision regulator and a pressure transducer calibrated for load measurement. Manual valves are provided to allow individual actuators to be isolated from the pneumatic circuit, hence removing the load from the associated test station.

Each test station has its own, independently controlled, lubricant circulation system.

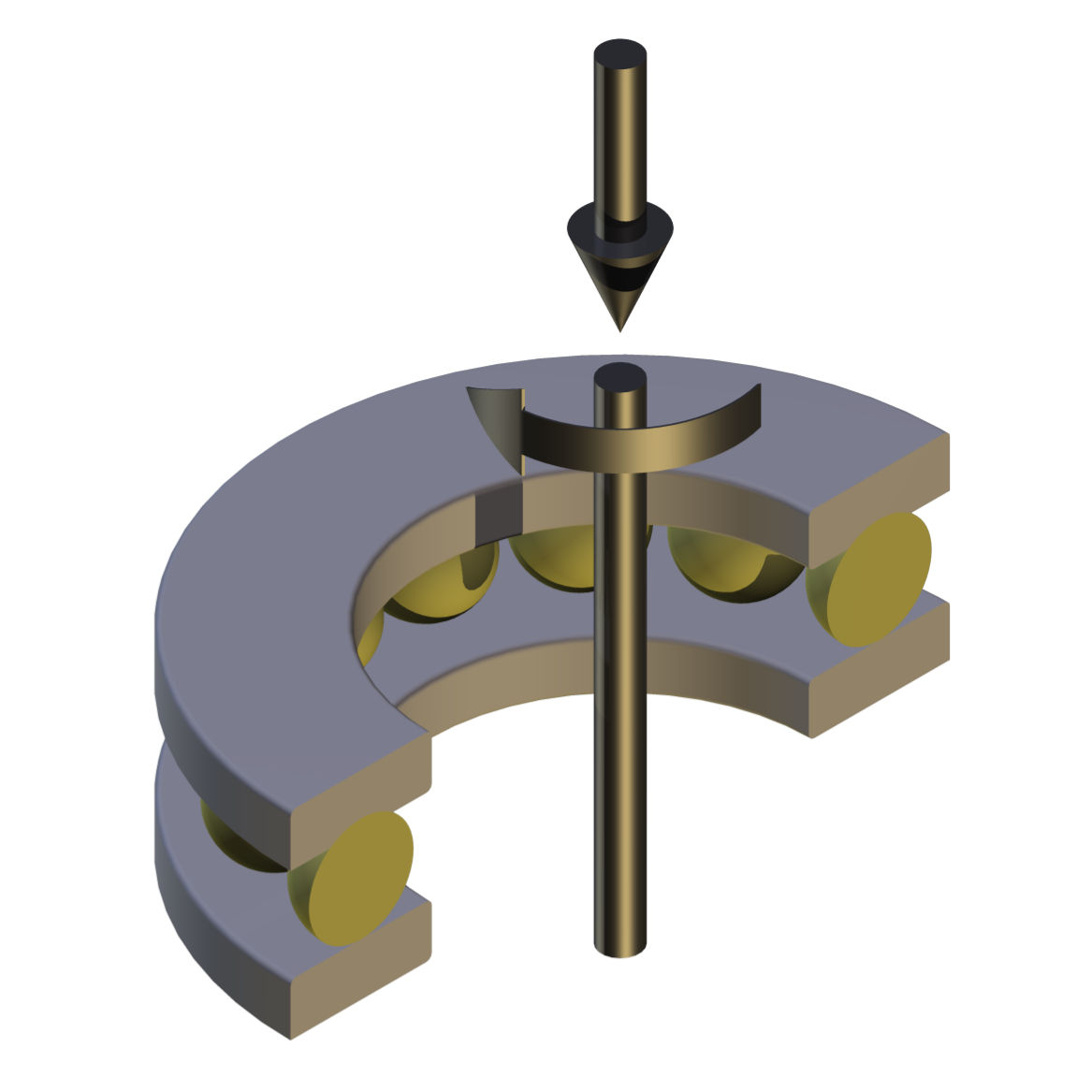

The machine installation footprint is kept to a minimum. It is simple to operate, so requires minimal training.RCF 5/1 Thrust Ball Bearing on Disc Adapter

This adapter uses one half of a standard size 51208 68 mm O/D 40 mm I/D thrust bearing, with the balls running between the normal bearing race and a flat disc. A cage is provided to retain the balls.

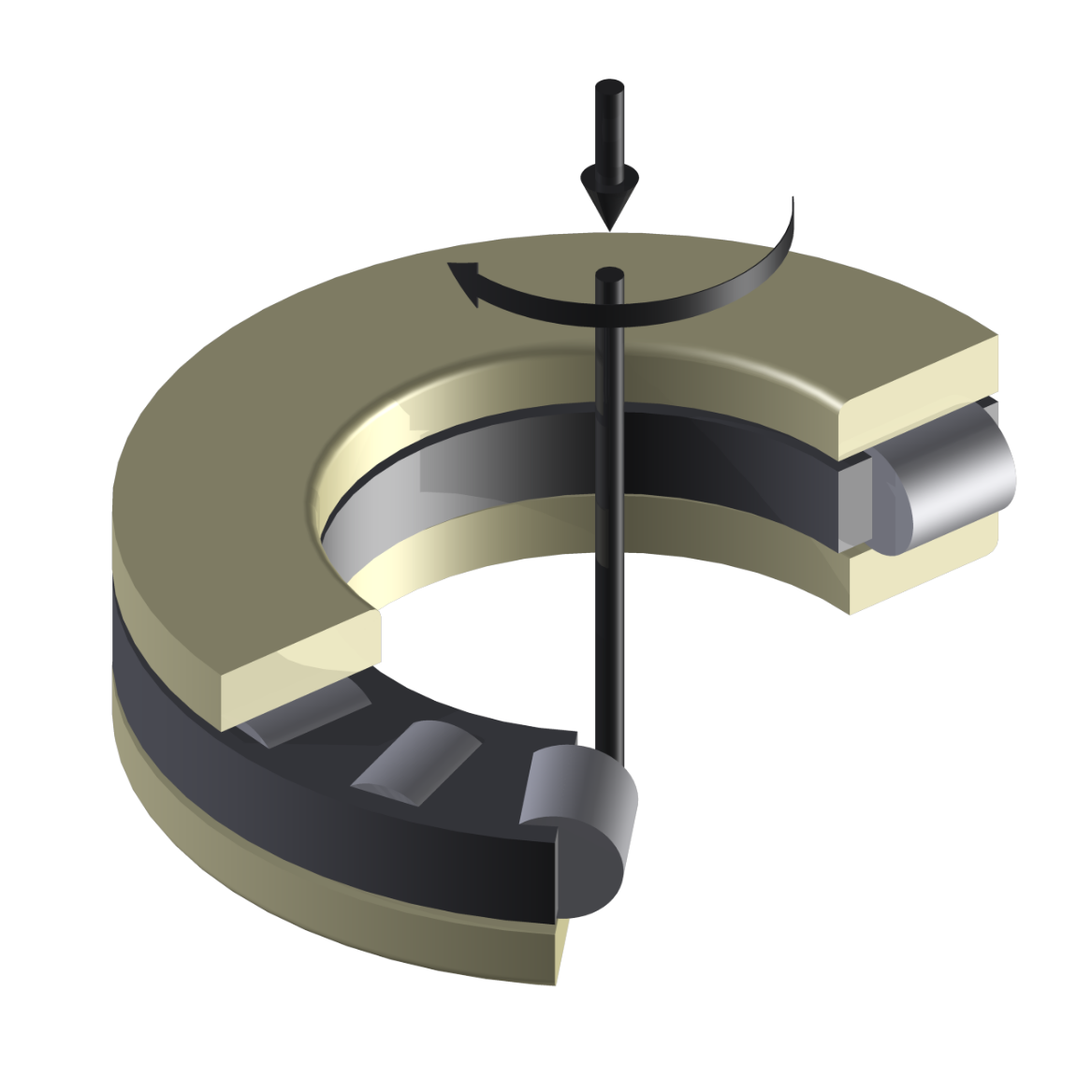

RCF 5/2 Roller Thrust Bearing on Disc Adapter

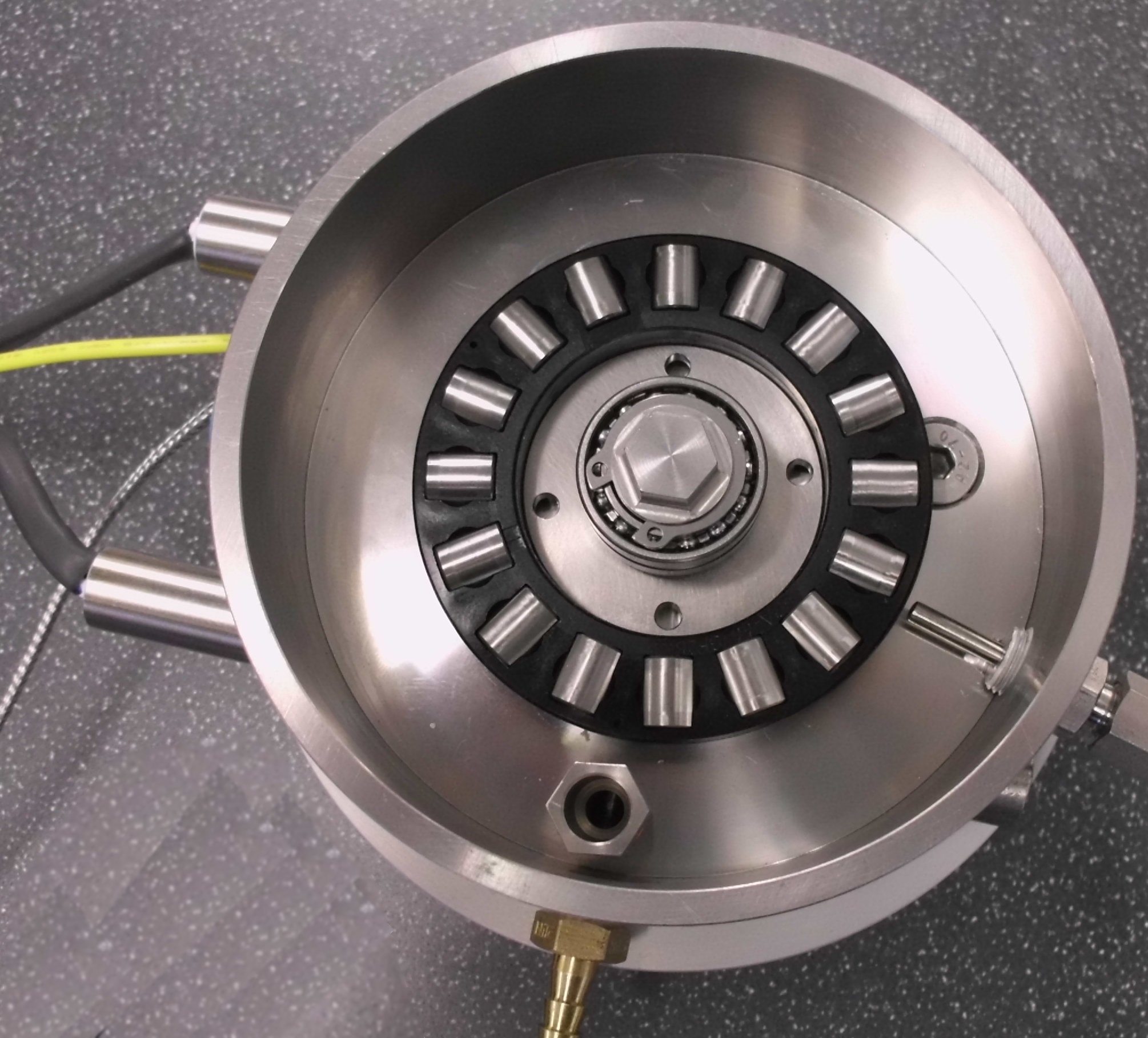

This adapter is essentially similar to RCF 5/1, but uses one half of a standard size 81208 TN roller thrust bearing, loaded against a flat lower disc sample, of chosen material. The standard bearing cage is used to locate the rollers, with the cage centred by a spindle mounted deep groove ball bearing.

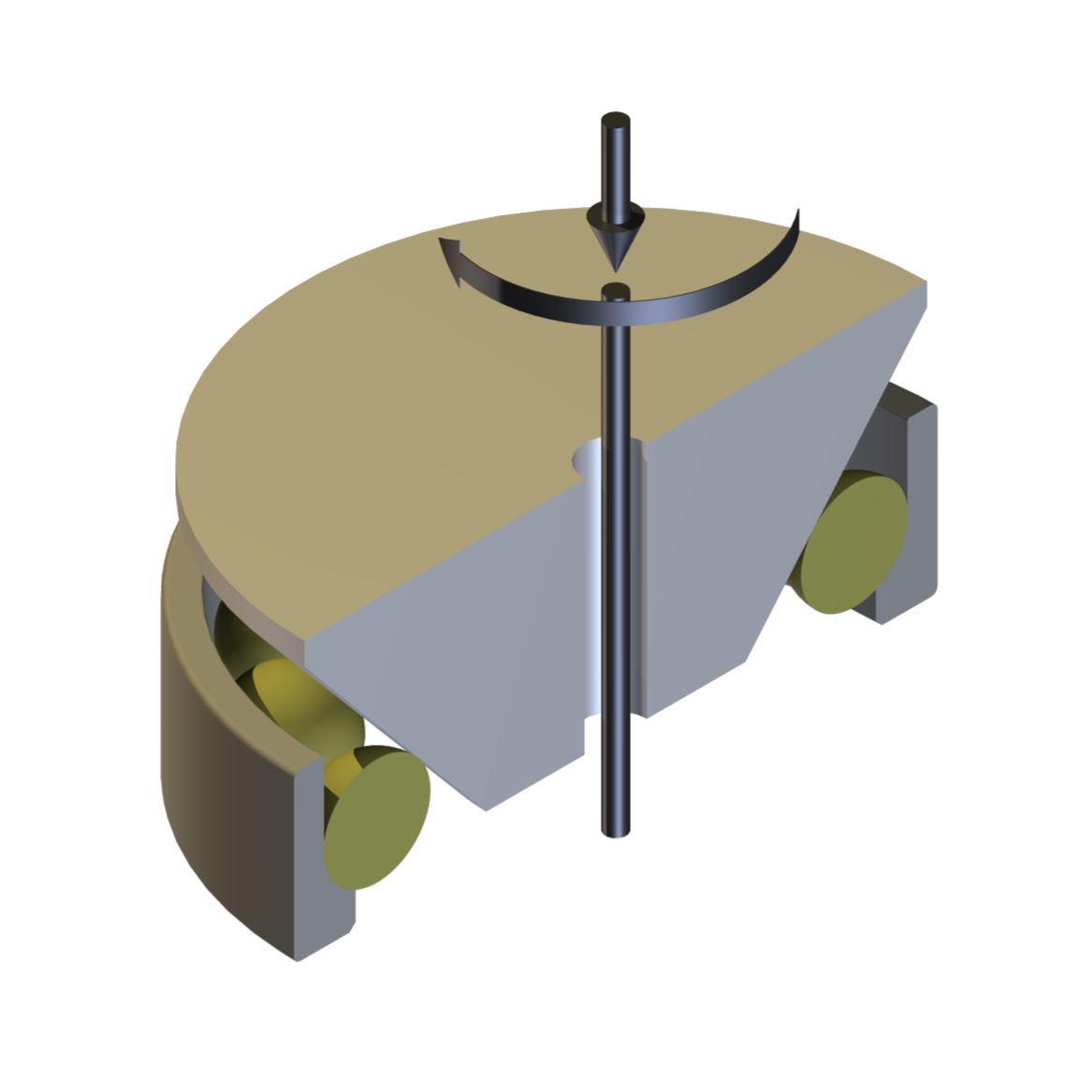

RCF 5/3 Cone on Angular Contact Bearing Adapter

This adapter uses a conical test sample loaded against the lower half of a size 7206 62 mm O/D 30 mm I/D angular contact bearing. The cone angle is designed to give a pure rolling contact. Contact stress can be increased further by removing balls from the bearing cage.

-

Technical Specifications

Test Geometry: Cone on Angular Contact Bearing Adapter (Bearing 7206) Thrust Ball Bearing on Disc Adapter (Bearing 51208) Roller Thrust Bearing on Disc Adapter (Bearing 81208 TN) Motion: Rotary Axial Load: 200 to 10,000 N Speed: 30 to 3,000 rpm Motor: 400 W @ 3,000 rpm Temperature: Ambient to 120°C Test Stations: Up to 6 Control: PLC Lubricant Service Module: Included Manually Controlled Parameters Load: Pneumatic – actuators in parallel Rotational Speed: Each test station independently controlled Temperature: Each test station independently controlled Vibration Level: Each test station Data Logged Parameters Load: Pressure transducer – one per installation Temperature: Yes – each test station Test Duration: Yes – each test station Services Electricity per Test Station: 220/240V, single phase, 50 Hz, 2 kW 110/120V, single phase, 60 Hz, 2 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Index Tags

ball thrust bearing hertzian contact roller thrust bearing rolling bearing materials rolling contact fatigue rolling contact fatigue machines -