-

Description

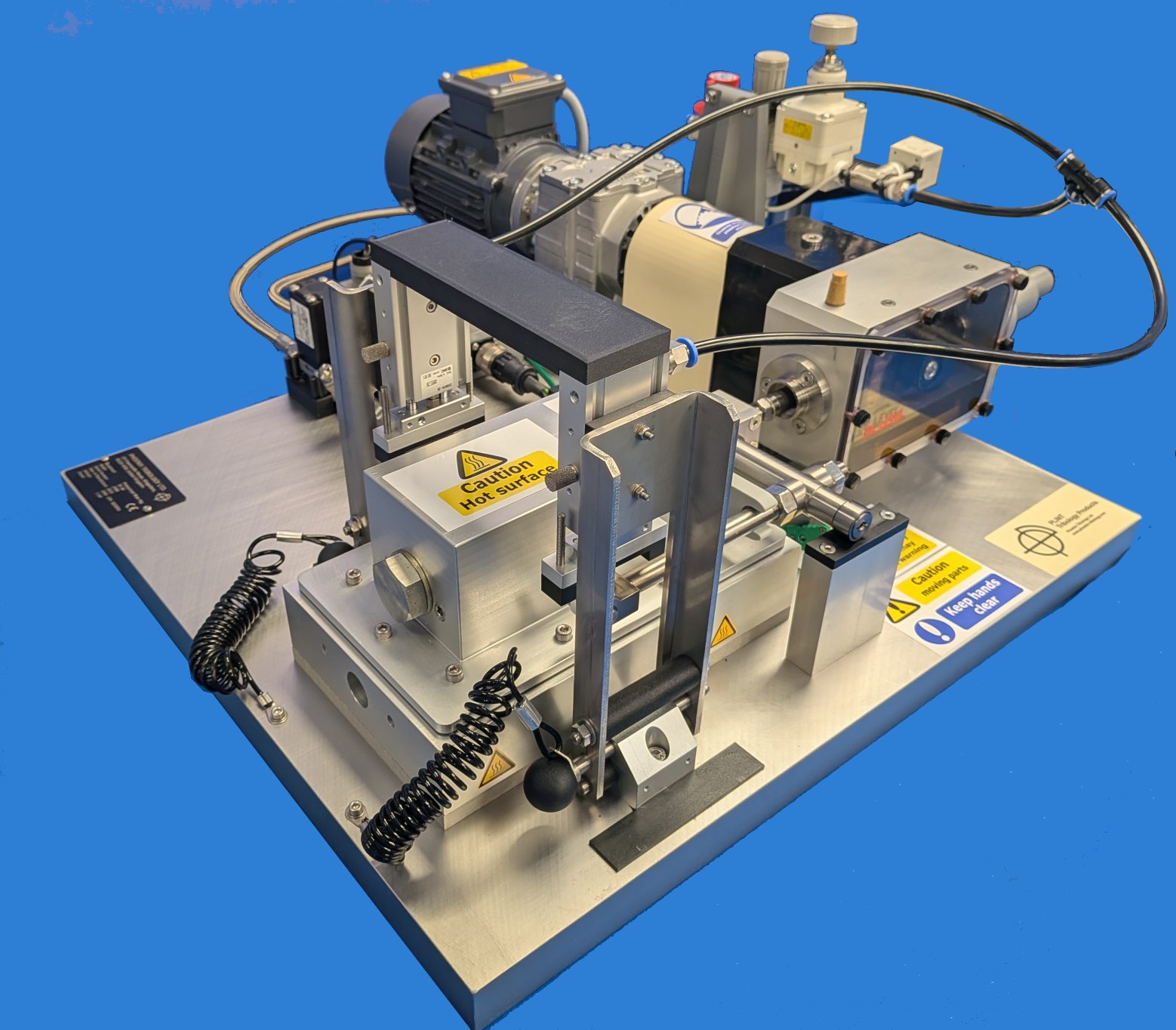

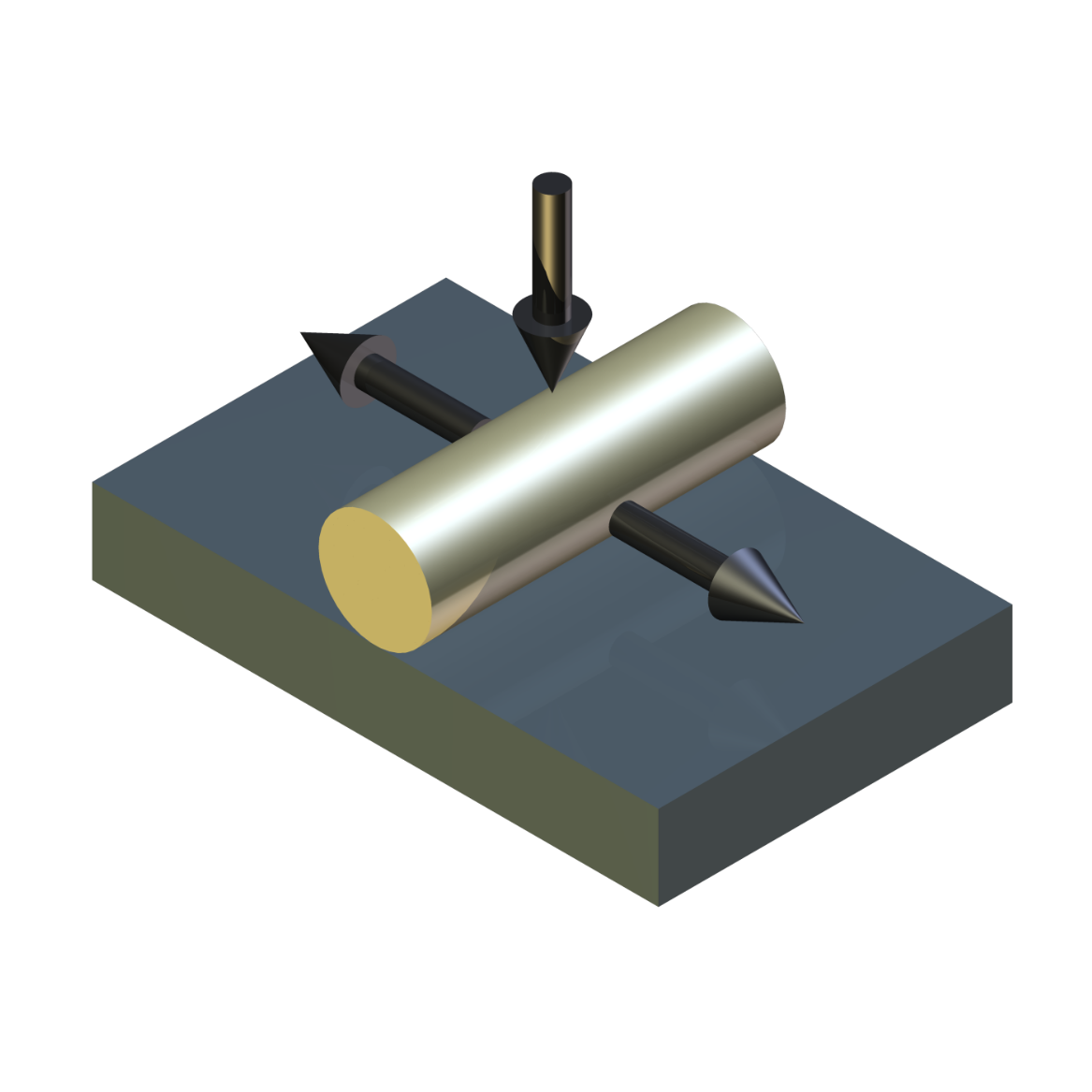

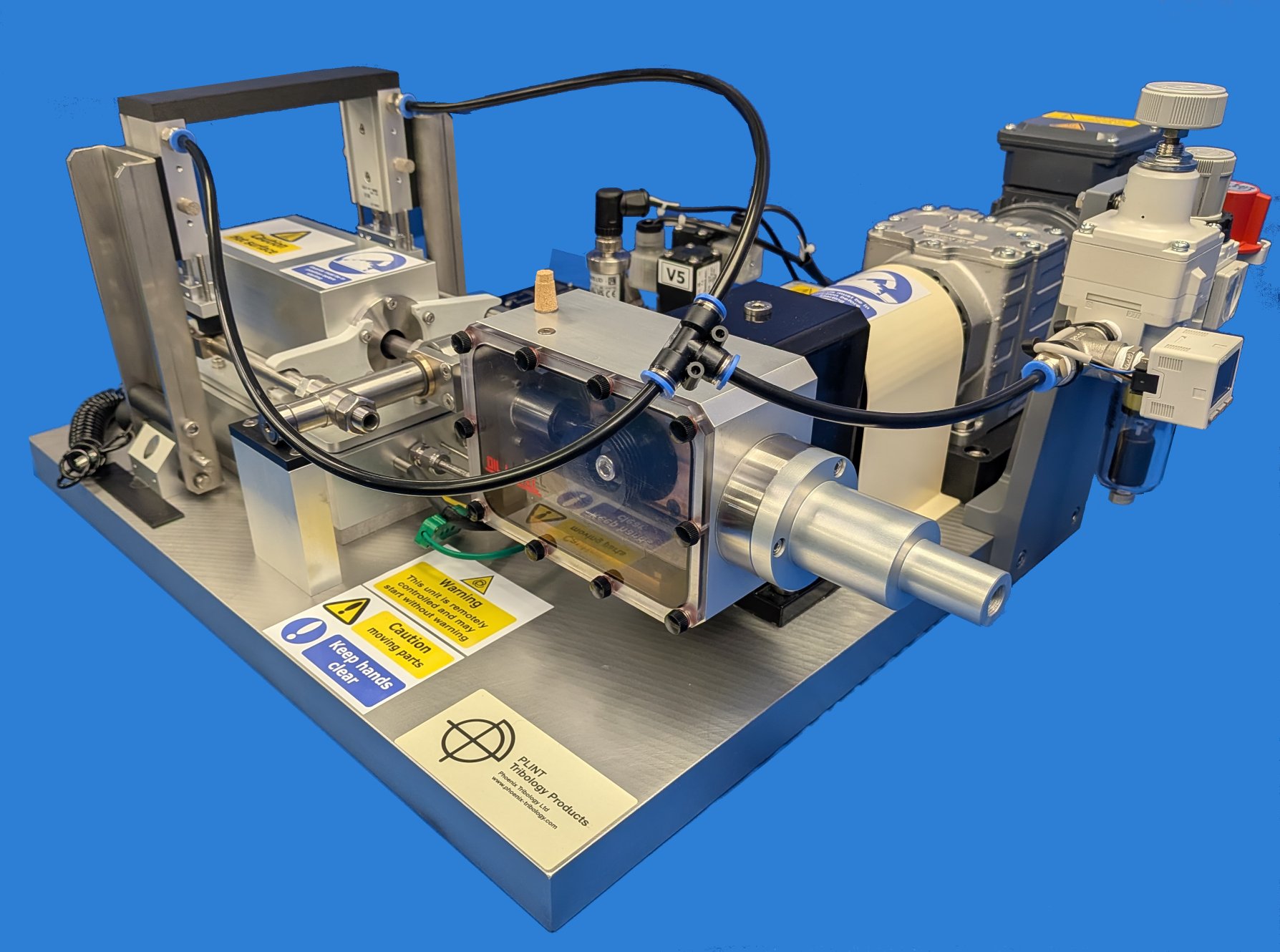

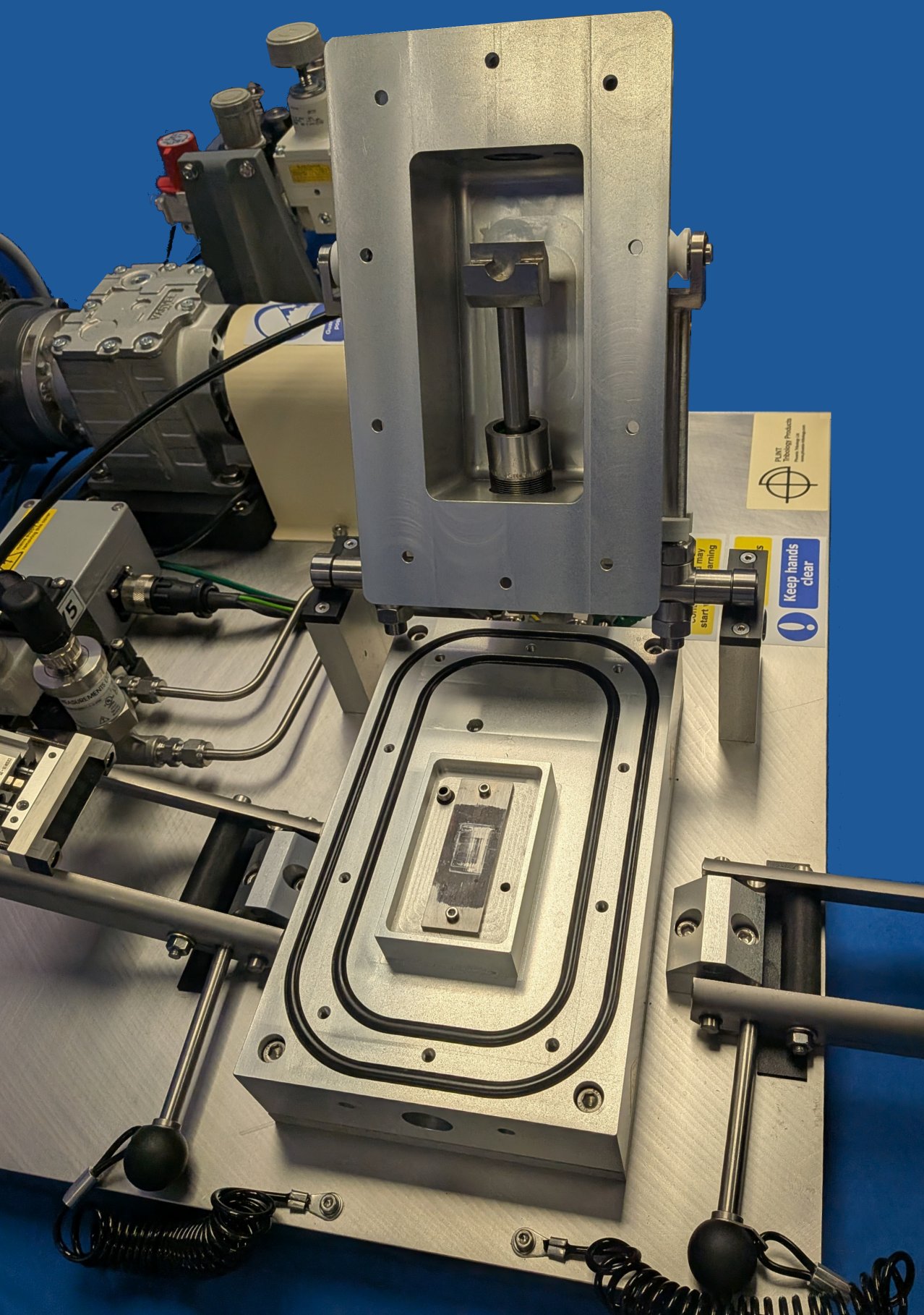

The TE 50 is a sealed and pressurised reciprocating wear generator. The standard test

configuration is line contact with a 6 mm diameter cylinder in contact with a flat surface. A

pressurised chamber fits over the moving specimen, rated to 3 bar, under either liquid or gas

pressure. The base of the test assembly includes locations for cartridge heaters and an optional

refrigerant probe.

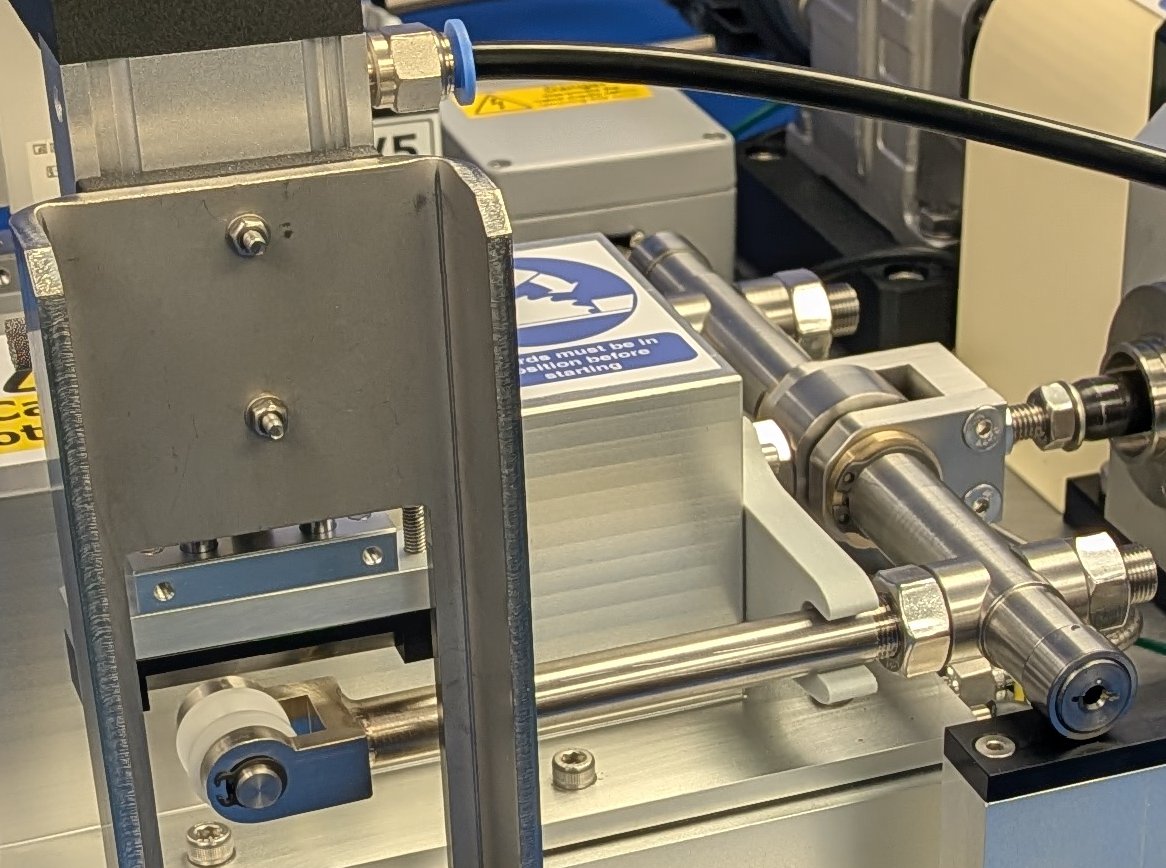

The moving specimen carrier is an arm that projects into the chamber through a stainless-steel

bellows and a sliding seal. The arm is connected via a bearing to a pivoted shaft, with outriggers

and support bearings at either end. A pneumatic cylinder at the end of each outrigger is used to

generate a moment of the pivoted shaft, which is reacted by the force between the moving

specimen and the counter-surface. The stainless-steel bellows provides the necessary freedom of

movement to allow effective transmission of load.

Reciprocating motion is generated using a scotch yoke drive from a standard TE 77 machine,

driven by a gear-motor.

For access to the specimens, the pneumatic cylinders are folded to the side and the chamber

fixing screws removed. The moving specimen arm and the chamber lid are then rotated together,

out of contact with the chamber base. -

Technical Specifications

Maximum Pressure: 3 bar Load Range: 15 to 150 N Temperature Range: Ambient to 150°C Heating Power: 400 W Temperature Sensor: K-type thermocouple Frequency Range: 0.5 to 5 Stroke Range: 0 – 25 mm Maximum Stroke: 25 mm Interface: Touch Screen PLC Motor: 0.18 kW with inline gearbox Plate Specimen: 72 x 23 x 3 Line Contact: 6 mm dia. X 16 mm length PLC Controlled Parameters

Frequency Temperature Test Duration Manually Controlled Parameters

Load Measured Parameters

Load Temperature Frequency Number of Cycles Services

Electricity: 220/240 V, single phase, 50/60 Hz, 1.5 kW Air: Clean Dry air, min. 5 BAR/ 0.5 MPa Installation

Benchtop Machine: 700 mm x 550 mm x 250 mm high, 50 kg Packing Specifications: 1000 x 700 x 500, 80 kg -

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com