-

Description

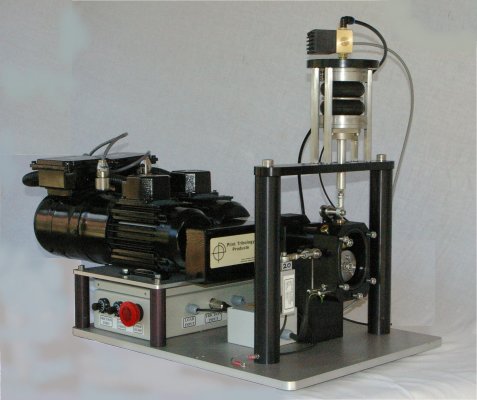

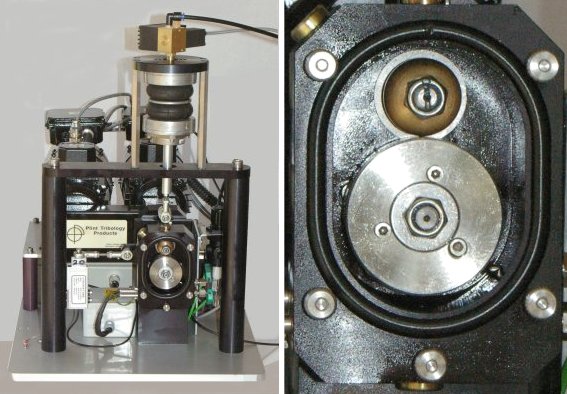

The TE 54 Mini Traction Machine has two motors, one to provide the input power and one to absorb the transmitted power. The design is of the “over-hung” roller type, with test rollers fitted over-hung on the end of the machine test spindles. Loading is via servo controlled pneumatic bellows, with force transducer feedback.

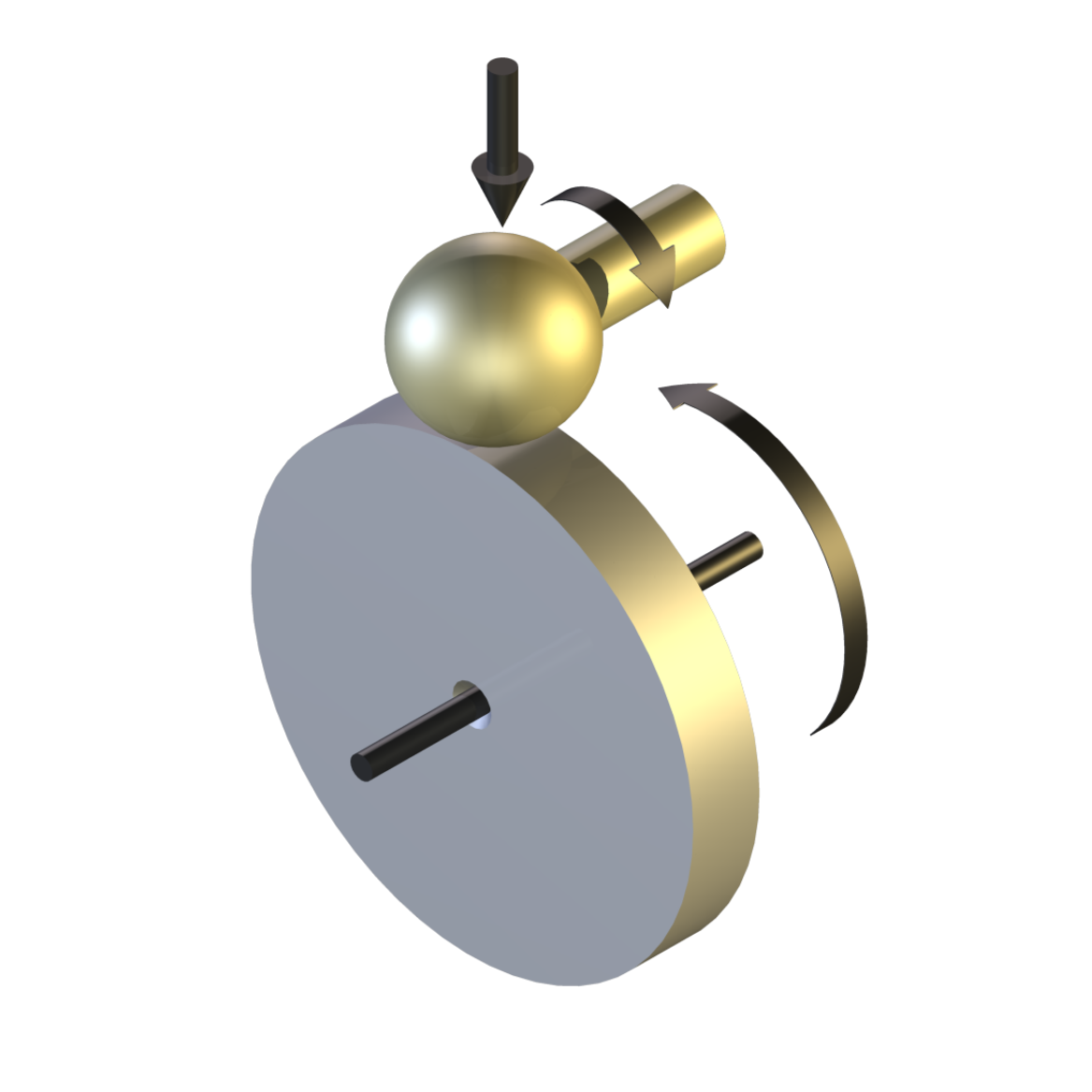

The ball-on-roller arrangement eliminates any possibility of spin or skew in the rolling contact and eliminates any uncertainty with regard ball or track diameter. With circumferential grinding of the roller, it eliminates all the an-isotropic materials properties associated with preparing the specimens.

Self-aligning Two Roller

In addition to the ball on disc arrangement, the TE 54 is also supplied with a self-aligning carrier to allow a 25 mm diameter by 8 mm wide roller to be mounted in place of the ball specimen, thus resulting in an 8 mm wide line contact. Thinner rollers can be manufactured in order to produce narrower line contacts.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.

Pre-programmed test sequences are provided for generating traction and Stribeck curves. -

Technical Specifications

Ball Specimen Diameter: 25 mm Upper Disc Specimen Diameter: 25 mm Upper Disc Specimen Width: 8 mm Lower Disc Specimen Diameter: 50 mm Maximum Ball Speed: 4,000 rpm Maximum Ring Speed: 2,000 rpm Maximum Surface Speed: 5.24 m/s Maximum Load: 500 N Maximum Hertz Pressure (steel): 2.0 GPa Oil Bath Temperature: ambient to 150°C Heater Power: 250 W Temperature Sensor: k-type thermocouple Loading System: Pneumatic bellows with force feedback AC Vector Drive: Two 0.75 kW closed loop with common DC link Motors: Continuous: 0.75 kW @ 50 Hz @ 1,450 rpm Feedback: 2,048 ppr encoder Drive Ratios: Motor:Ball: 1:1 Motor:Ring: 2:1 Interface: Serial Link Interface Module Software: COMPEND 2000 Controlled Parameters Motor speed Motor speed difference Applied load Test bath temperature Measured Parameters: Motor speed Motor speed difference Applied load Traction force Test bath temperature Derived Parameters Entrainment Velocity Sliding Velocity Slide/Roll Ratio Traction Coefficient Services Electricity: 380/415 V, three phase, 50/60 Hz, 1.5 kW, with neutral & earth 220/240 V, three phase, 50/60 Hz, 1.5 kW, with neutral & earth Clean, dry air: 4 cfm at 8 bar (120 psi) -

Overview Videos

Machine Overview

-

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com