-

Description

The TE 65 Multiplex Sand/Wheel Abrasion Tester is designed to perform tests according to the conditions described in the following methods:

- ASTM G65 Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

- ASTM G105 Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests

- ASTM B611 Test Method for Abrasive Wear Resistance of Cemented Carbides

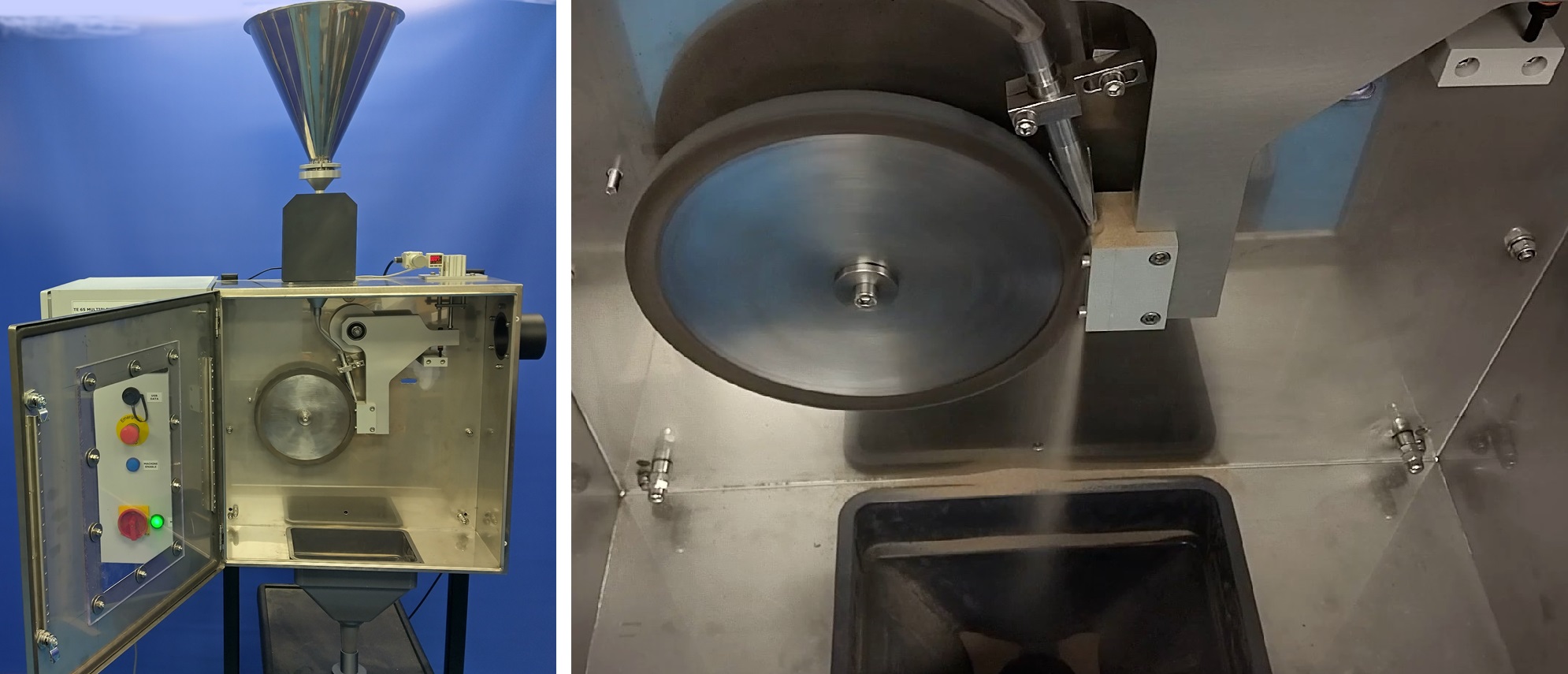

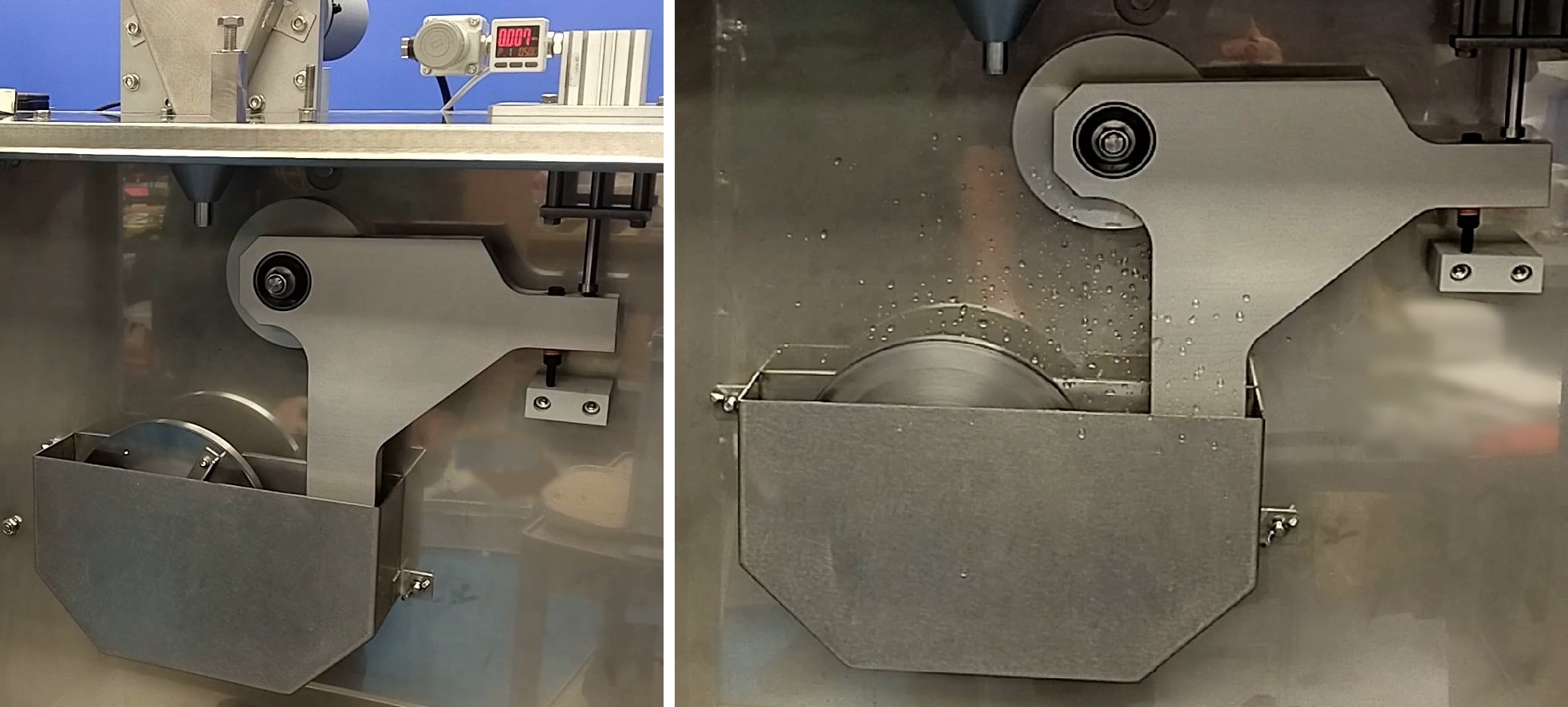

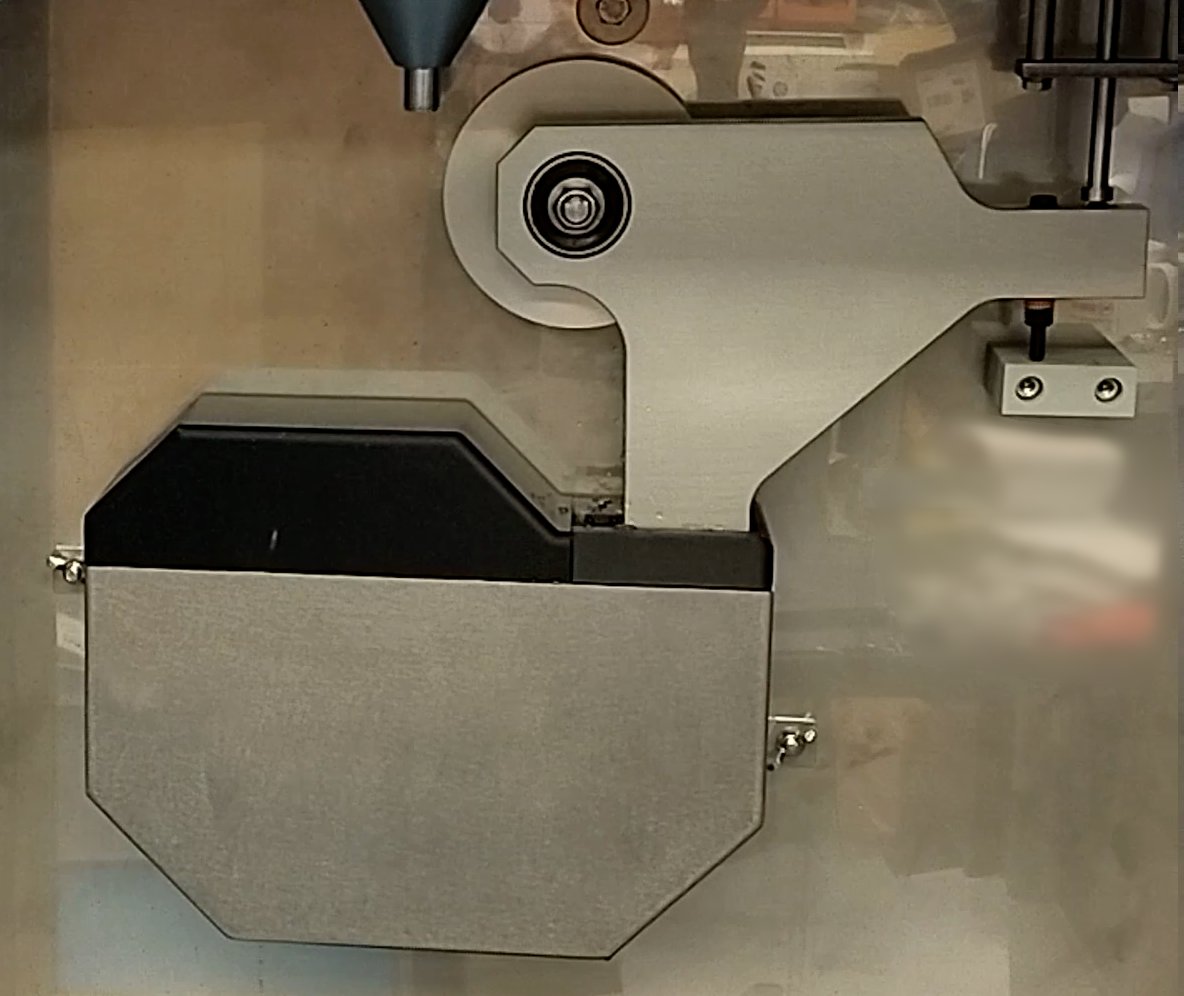

The machine is floor standing with test assemblies mounted on a back-plate and abradant discharged downwards into a collecting hopper. Load is applied by pneumatic cylinder in conjunction with a manually adjusted precision regulator, with a pressure sensor for load measurement.

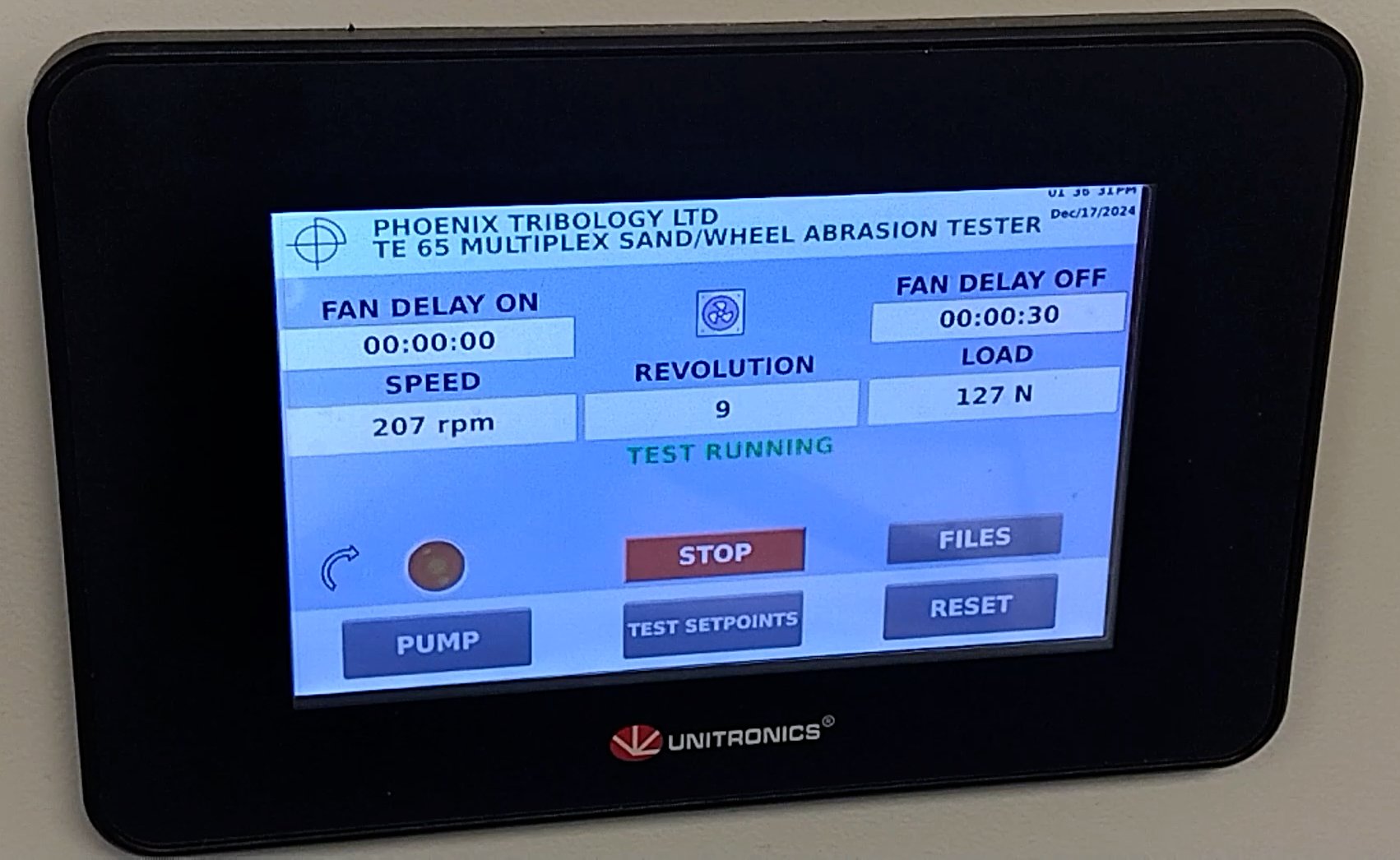

Speed set-point control is manual, implemented via a PLC, with input via touch-screen.

Standard Test Configurations

ASTM G65 uses hopper fed sand, which is delivered through a defined geometry nozzle.

Enhanced control of the particle flow rate is achieved by the addition of a precision feed system.

For ASTM G105 and B611, a slurry trough is fitted, with the specified slurry agitated by vanes on the rotating wheel. The load arm is repositioned to accommodate the smaller diameter test wheels, and the direction of rotation is reversed.

To reduce splashing, a cover is provided for the slurry trough.

-

Technical Specifications

ASTM Conditions Wheel Speed: 10 to 350 rpm 9″ rubber wheel as per ASTM G65 Wheel Types: 6.65″ steel wheel as per ASTM B611 7″ rubber wheel as per ASTM G105 Load: 20 to 350 N Motor Type: a.c. motor with frequency inverter drive Specimen Size: 25 mm x 58 mm Specimen Thickness: 6 mm to 16 mm Test Types: ASTM G 65, ASTM G 105, ASTM B 611 Services Electricity: 220/240V, single phase, 50 Hz, 1 kW 110/120 V, single phase, 60 Hz, 1 kW -

Overview Videos

-

Index Tags

-

Download the Machine Leaflet

Call us on +44 (0) 1635 298279

Email : info@phoenix-tribology.com

Email : info@phoenix-tribology.com